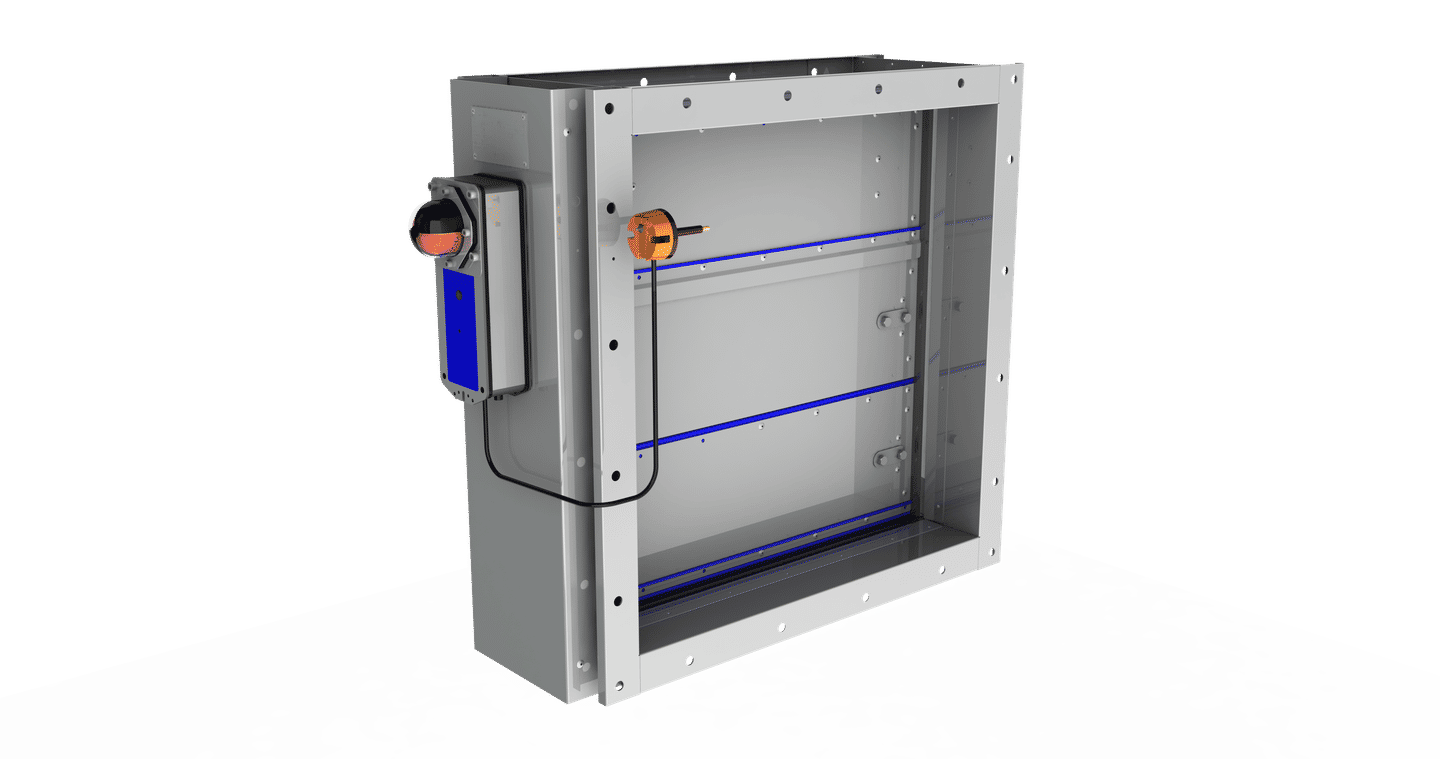

Product / FCE

Overview

- Certified by Centrum Techniki Okretowej S.A.

- Automatic electrical operation system

- Blades contain silicone seals (effective up to 300 ºC) for low leakage in normal conditions and thermal expansion graphite seals (effective from 150 ºC) to increase tightness in a case of fire

- Blades contain ceramic wool insulation or calcium silicate fire protective board depending on fire resistance class

- Low weight due to double skin blade structure

- Closed blade leakage to EN 1751, Class 3 size >=200×200

- Casing leakage to EN 1751, Class C

- Maximum duct pressure for damper construction 5000 Pa (3mm casing), 3000 Pa (1mm casing) and maximum air velocity 15 m/s

- Normal operation temperature for damper between -30 ºC to +50 ºC. Actuator and component selection can have an effect on this temperature range. Other temperatures available on request

- Option of circular connection

- Available as ATEX/IECEx certified

- SIL 2 safety assessment certificate available for the damper on specific terms

Specification

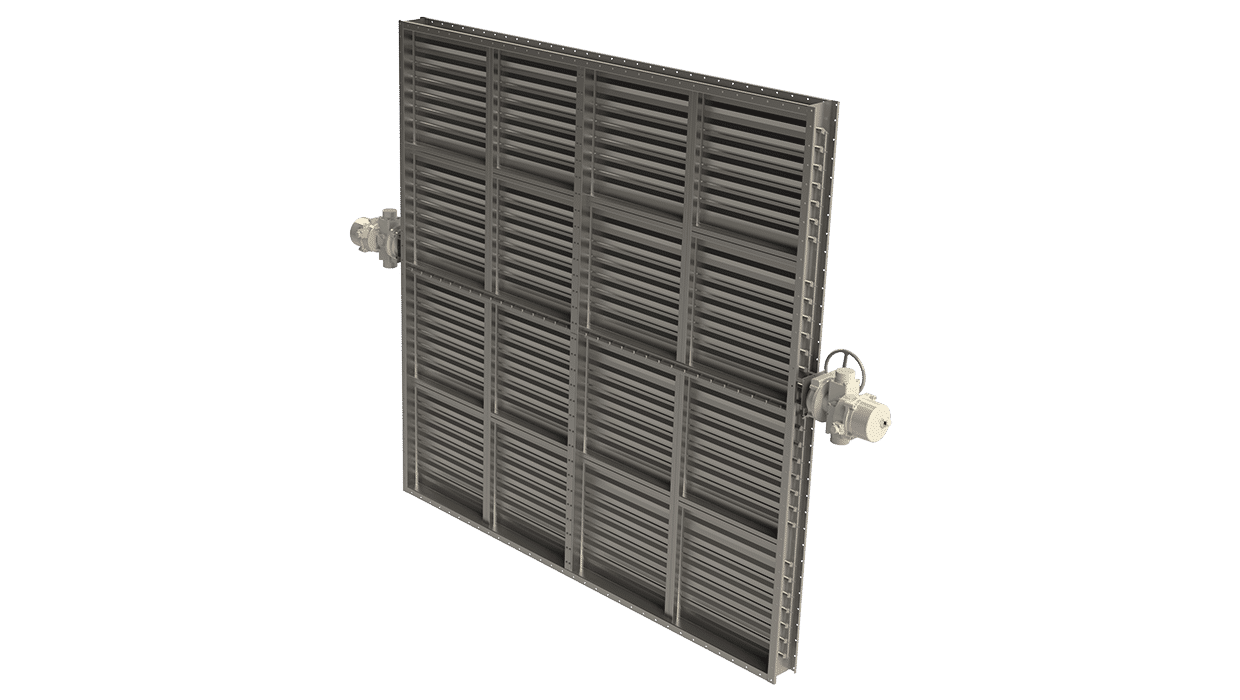

Halton FCE fire dampers are CE-marked according EN 15650:2010 and tested according to EN 1366-2 standard. Halton FCE fire dampers are used as safety-related components in ventilation systems to prevent fire and smoke spreading through ducting.

The FCE fire damper can be installed in rectangular ducts in solid walls, ceilings and lightweight partition wall. During normal operation, the fire damper is in the open position and does not cause significant pressure loss, noise or flow disturbance.

Dimensions and Material Thickness

The FCE fire dampers meet international standards for both rectangular (width B 150-1000 mm with 25 mm division and height H 150-1000 mm with 50 mm division) and circular ducts (Ø100-1000 mm).

Standard flanges height 50 mm and drilling according to ISO 15138 standards. Frame thickness 1 mm to 3 mm. Blades are made of two sheets, each of being 1 mm thick (sandwich design).

| DIMENSIONS | ØC | F | P1 | P2 | BM |

| If longest side < 350 | 10 | 50 | 75…150 | 75…150 | 20 |

| If longest side 351…1000 | 12 | 50 | 75…150 | 75…150 | 30 |

| ACTUATOR | T | T (external limit switch) |

| Belimo BF | 112 | 163 |

| Schischek BF | 132 | 184 |

| QT.EX_MFD | 95 | 197 |

Fire classification according to EN 13501-3

EI 60 (ve ho i ↔ o ) S

E 120 (ve ho i ↔ o ) S

E: Integrity (against flames & hot gases)

I: Insulation (against heat)

S: Smoke leakage (against gases & smoke)

ve: Vertical installation

ho: Horizontal installation

i ↔ o: Fire direction, outside & inside duct

60 Minutes integrity and insulation

120 Minutes integrity

FCE leakage in fire conditions

Test pressure 300 Pa. Damper size 1000×1000 mm. Test according to EN 1366-2.

FCE, general drawings

Material and Finishing

| PART | MATERIAL | FINISHING |

| Frame | Carbon steel (3 mm) Steel (1 mm) |

Hot-dip galvanized / ISO 1464 Z275 / EN 10346:2015 |

| Frame | Stainless steel EN 1.4301 (AISI304), EN 1.4404 (AISI316), EN 1.4432 (AISI316L) |

(3 mm) Pickling / (1 mm) N/A |

| Blades | Steel | Z275 / EN 10346:2015 |

| Blades | Stainless steel EN 1.4301 (AISI304), EN 1.4404 (AISI316), EN 1.4432 (AISI316L) |

– |

| Blade insulation | Calcium silicate (EI 60 S) Ceramic wool (E 120 S) |

– |

| Maintenance-free bearings | Oil bronze | – |

| Bearings | EN 1.4404 (AISI316) (Available as an option) |

– |

| Shafts | Stainless steel EN 1.4404 (AISI316) |

– |

Product Models and Accessories

Halton FCE is available with following actuators:

- FCE-EL: Electrical spring return motor; standard actuators being 24 V to 230 V. The motor contains built-in open-closed limit switches. Separate junction box included in the EL-model. A wide range of Ex actuators available.

HSO: Halton Smart Override function for HVAC damper black-start available. With automatic reset function when power is reinstated.

A wide range of accessories available.

Operation principles

If temperature increases (≥72°C) in case of fire or hot gases the damper blade closes automatically. Alternatively, the FCE damper may be released by a local switch or common building automation system.

Weights

Weights according to fire resistance class ES 120

Standard Halton Marine FCE dampers (kg), without an actuator, frame thickness 1 mm

| H/Height

(mm) |

B/Width (mm) | |||||||||||||||||

| 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | |

| 150 | 7 | 7 | 8 | 9 | 10 | 11 | 11 | 12 | 13 | 14 | 15 | 16 | 16 | 17 | 18 | 19 | 20 | 21 |

| 200 | 7 | 8 | 9 | 10 | 11 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 17 | 18 | 19 | 20 | 21 | 22 |

| 250 | 8 | 9 | 10 | 11 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 17 | 18 | 19 | 20 | 21 | 22 | 22 |

| 300 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 |

| 350 | 11 | 12 | 13 | 14 | 15 | 16 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 400 | 12 | 13 | 14 | 15 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 |

| 450 | 14 | 16 | 17 | 18 | 20 | 21 | 22 | 23 | 25 | 26 | 27 | 29 | 30 | 31 | 33 | 34 | 35 | 36 |

| 500 | 16 | 17 | 18 | 19 | 21 | 22 | 23 | 25 | 26 | 27 | 29 | 30 | 31 | 32 | 34 | 35 | 36 | 38 |

| 550 | 17 | 18 | 19 | 21 | 22 | 23 | 24 | 26 | 27 | 28 | 30 | 31 | 32 | 34 | 35 | 36 | 37 | 39 |

| 600 | 18 | 19 | 20 | 22 | 23 | 24 | 26 | 27 | 28 | 29 | 31 | 32 | 33 | 35 | 36 | 37 | 39 | 40 |

| 650 | 20 | 21 | 23 | 24 | 26 | 28 | 29 | 31 | 32 | 34 | 35 | 37 | 38 | 40 | 41 | 43 | 44 | 46 |

| 700 | 21 | 23 | 24 | 26 | 27 | 29 | 30 | 32 | 33 | 35 | 36 | 38 | 39 | 41 | 42 | 44 | 45 | 47 |

| 750 | 22 | 24 | 25 | 27 | 28 | 30 | 31 | 33 | 34 | 36 | 37 | 39 | 40 | 42 | 43 | 45 | 47 | 48 |

| 800 | 23 | 25 | 26 | 28 | 29 | 31 | 32 | 34 | 35 | 37 | 38 | 40 | 42 | 43 | 45 | 46 | 48 | 49 |

| 850 | 25 | 27 | 29 | 31 | 32 | 34 | 36 | 38 | 39 | 41 | 43 | 45 | 46 | 48 | 50 | 52 | 53 | 55 |

| 900 | 27 | 28 | 30 | 32 | 34 | 35 | 37 | 39 | 41 | 42 | 44 | 46 | 48 | 49 | 51 | 53 | 55 | 56 |

| 950 | 28 | 29 | 31 | 33 | 35 | 36 | 38 | 40 | 42 | 43 | 45 | 47 | 49 | 50 | 52 | 54 | 56 | 57 |

| 1000 | 29 | 30 | 32 | 34 | 36 | 37 | 39 | 41 | 43 | 44 | 46 | 48 | 50 | 51 | 53 | 55 | 57 | 58 |

Standard Halton Marine FCE dampers (kg), without an actuator, frame thickness 3 mm

| H/Height

(mm) |

B/Width (mm) | |||||||||||||||||

| 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | |

| 150 | 12 | 12 | 14 | 15 | 16 | 18 | 19 | 20 | 21 | 22 | 23 | 25 | 26 | 27 | 28 | 29 | 31 | 32 |

| 200 | 12 | 14 | 15 | 16 | 17 | 19 | 20 | 21 | 22 | 24 | 25 | 26 | 27 | 28 | 29 | 31 | 32 | 33 |

| 250 | 14 | 15 | 16 | 17 | 18 | 20 | 21 | 22 | 24 | 25 | 26 | 27 | 28 | 29 | 31 | 32 | 33 | 34 |

| 300 | 16 | 17 | 19 | 20 | 22 | 23 | 25 | 26 | 28 | 29 | 30 | 32 | 33 | 35 | 36 | 37 | 39 | 40 |

| 350 | 17 | 19 | 20 | 22 | 23 | 25 | 26 | 28 | 29 | 30 | 32 | 33 | 35 | 36 | 38 | 39 | 40 | 42 |

| 400 | 19 | 20 | 22 | 23 | 24 | 26 | 28 | 29 | 31 | 32 | 33 | 35 | 36 | 38 | 39 | 40 | 42 | 43 |

| 450 | 22 | 23 | 25 | 27 | 28 | 30 | 32 | 33 | 35 | 36 | 38 | 40 | 41 | 43 | 45 | 46 | 48 | 50 |

| 500 | 23 | 25 | 26 | 28 | 30 | 31 | 33 | 35 | 36 | 38 | 40 | 41 | 43 | 44 | 46 | 48 | 49 | 51 |

| 550 | 25 | 26 | 28 | 30 | 31 | 33 | 34 | 36 | 38 | 39 | 41 | 43 | 44 | 46 | 48 | 49 | 51 | 52 |

| 600 | 26 | 28 | 29 | 31 | 33 | 34 | 36 | 38 | 39 | 41 | 42 | 44 | 46 | 47 | 49 | 51 | 52 | 54 |

| 650 | 29 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 43 | 45 | 47 | 49 | 51 | 53 | 55 | 56 | 58 | 60 |

| 700 | 30 | 32 | 34 | 36 | 37 | 39 | 41 | 43 | 45 | 47 | 49 | 51 | 52 | 54 | 56 | 58 | 60 | 62 |

| 750 | 32 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 59 | 61 | 63 |

| 800 | 33 | 35 | 37 | 39 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 53 | 55 | 57 | 59 | 61 | 63 | 65 |

| 850 | 35 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 | 63 | 65 | 67 | 69 | 71 |

| 900 | 37 | 39 | 41 | 43 | 45 | 47 | 49 | 51 | 54 | 56 | 58 | 60 | 62 | 64 | 66 | 68 | 70 | 72 |

| 950 | 38 | 40 | 43 | 45 | 47 | 49 | 51 | 53 | 55 | 57 | 59 | 61 | 63 | 65 | 68 | 70 | 72 | 74 |

| 1000 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 59 | 61 | 63 | 65 | 67 | 69 | 71 | 73 | 75 |

| ACTUATOR OPTIONS | CLOSING TIME | MATERIAL | WEIGHT (APPR.) |

| Ex/InMax-BF | 3/10 seconds | Aluminium | 3,5 kg |

| Ex/InMax-BF | 3/10 seconds | Stainless steel | 7,0 kg |

| QT.Ex-MFD | 3 seconds | High Tech Polymer | 4,1 kg |

| BF230-T | 16 seconds | Steel | 3,1 kg |

| BF24-T | 16 seconds | Steel | 2,8 kg |

Weights according to fire resistance class EI 60 S

Standard Halton Marine FCE dampers (kg), without an actuator, frame thickness 1 mm

| H/Height

(mm) |

B/Width (mm) | |||||||||||||||||

| 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | |

| 150 | 7 | 8 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

| 200 | 8 | 9 | 10 | 11 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 250 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| 300 | 11 | 12 | 13 | 14 | 16 | 17 | 18 | 19 | 21 | 22 | 23 | 25 | 26 | 27 | 28 | 30 | 31 | 32 |

| 350 | 12 | 13 | 14 | 16 | 17 | 18 | 20 | 21 | 22 | 24 | 25 | 26 | 27 | 29 | 30 | 31 | 33 | 34 |

| 400 | 13 | 14 | 16 | 17 | 18 | 20 | 21 | 22 | 24 | 25 | 26 | 28 | 29 | 30 | 32 | 33 | 34 | 36 |

| 450 | 15 | 17 | 18 | 20 | 22 | 23 | 25 | 26 | 28 | 30 | 31 | 33 | 34 | 36 | 38 | 39 | 41 | 42 |

| 500 | 16 | 18 | 20 | 21 | 23 | 25 | 26 | 28 | 29 | 31 | 33 | 34 | 36 | 38 | 39 | 41 | 42 | 44 |

| 550 | 18 | 19 | 21 | 23 | 24 | 26 | 28 | 29 | 31 | 33 | 34 | 36 | 38 | 39 | 41 | 43 | 44 | 46 |

| 600 | 19 | 21 | 22 | 24 | 26 | 27 | 29 | 31 | 32 | 34 | 36 | 38 | 39 | 41 | 43 | 44 | 46 | 48 |

| 650 | 21 | 23 | 25 | 27 | 29 | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 | 48 | 50 | 52 | 54 |

| 700 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 48 | 49 | 50 | 52 | 54 | 56 |

| 750 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 |

| 800 | 25 | 27 | 29 | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 | 49 | 51 | 53 | 56 | 58 | 60 |

| 850 | 27 | 29 | 32 | 34 | 36 | 39 | 41 | 43 | 46 | 48 | 50 | 52 | 55 | 57 | 59 | 62 | 64 | 66 |

| 900 | 28 | 31 | 33 | 35 | 38 | 40 | 42 | 45 | 47 | 49 | 52 | 54 | 56 | 59 | 61 | 63 | 66 | 68 |

| 950 | 29 | 32 | 34 | 37 | 39 | 41 | 44 | 46 | 48 | 51 | 53 | 56 | 58 | 60 | 63 | 65 | 67 | 70 |

| 1000 | 31 | 33 | 36 | 38 | 40 | 43 | 45 | 48 | 50 | 52 | 55 | 57 | 60 | 62 | 64 | 67 | 69 | 72 |

Standard Halton Marine FCE dampers (kg), without an actuator, frame thickness 3 mm

| H/Height

(mm) |

B/Width (mm) | |||||||||||||||||

| 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | |

| 150 | 12 | 13 | 14 | 15 | 17 | 18 | 20 | 21 | 22 | 23 | 25 | 26 | 27 | 29 | 30 | 31 | 32 | 34 |

| 200 | 13 | 14 | 15 | 17 | 18 | 20 | 21 | 22 | 24 | 25 | 26 | 28 | 29 | 30 | 32 | 33 | 34 | 36 |

| 250 | 14 | 15 | 17 | 18 | 19 | 21 | 23 | 24 | 25 | 27 | 28 | 29 | 31 | 32 | 33 | 35 | 36 | 37 |

| 300 | 16 | 18 | 20 | 21 | 23 | 25 | 27 | 28 | 30 | 31 | 33 | 35 | 36 | 38 | 39 | 41 | 43 | 44 |

| 350 | 18 | 20 | 21 | 23 | 25 | 27 | 28 | 30 | 32 | 33 | 35 | 37 | 38 | 40 | 41 | 43 | 45 | 46 |

| 400 | 20 | 21 | 23 | 25 | 26 | 28 | 30 | 32 | 33 | 35 | 37 | 38 | 40 | 42 | 43 | 45 | 47 | 48 |

| 450 | 23 | 25 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 53 | 55 |

| 500 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 |

| 550 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 |

| 600 | 27 | 29 | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 | 62 |

| 650 | 30 | 32 | 34 | 37 | 39 | 41 | 44 | 46 | 48 | 50 | 53 | 55 | 57 | 60 | 62 | 64 | 66 | 69 |

| 700 | 31 | 34 | 36 | 38 | 41 | 43 | 45 | 48 | 50 | 52 | 56 | 57 | 59 | 62 | 64 | 66 | 68 | 71 |

| 750 | 33 | 35 | 38 | 40 | 42 | 45 | 47 | 49 | 52 | 54 | 56 | 59 | 61 | 63 | 66 | 68 | 71 | 73 |

| 800 | 35 | 37 | 39 | 42 | 44 | 46 | 49 | 51 | 54 | 56 | 58 | 61 | 63 | 65 | 68 | 70 | 73 | 75 |

| 850 | 37 | 40 | 42 | 45 | 48 | 50 | 53 | 56 | 58 | 61 | 63 | 66 | 69 | 71 | 74 | 77 | 79 | 82 |

| 900 | 39 | 41 | 44 | 47 | 49 | 52 | 55 | 57 | 60 | 63 | 65 | 68 | 71 | 73 | 76 | 79 | 81 | 84 |

| 950 | 40 | 43 | 46 | 48 | 51 | 54 | 56 | 59 | 62 | 65 | 67 | 70 | 73 | 75 | 78 | 81 | 83 | 86 |

| 1000 | 42 | 44 | 47 | 50 | 53 | 55 | 58 | 61 | 64 | 66 | 69 | 72 | 75 | 77 | 80 | 83 | 86 | 88 |

| ACTUATOR OPTIONS | CLOSING TIME | MATERIAL | WEIGHT (APPR.) |

| Ex/InMax-BF | 3/10 seconds | Aluminium | 3,5 kg |

| Ex/InMax-BF | 3/10 seconds | Stainless steel | 7,0 kg |

| QT.Ex-MFD | 3 seconds | High Tech Polymer | 4,1 kg |

| BF230-T | 16 seconds | Steel | 3,1 kg |

| BF24-T | 16 seconds | Steel | 2,8 kg |

Installation

The FCE fire damper can be installed into rectangular HVAC ducts that penetrate solid or lightweight partition walls and ceilings. The damper ease of installation on-site makes it an ideal choice compared to other fire dampers. The damper is installed 75-1000 mm away from the wall by using a fire-rated duct. This installation method follows the requirements of the above-mentioned standards and therefore the final damper arrangement provides a fully compliant installation.

Note regarding wall installation

At wall installation the blade orientation must always be in horizontal plane.

Product Code

Downloads

-

Halton FCE datasheet 2025

Data

English -

ATEX Certificate for Halton FCE and FDH

Data

English -

Construction Product Regulation (CPR) – FCE

Data

English -

Declaration of Performance (DoP) – FCE

Data

English -

EAC Certificate for Halton FDA, FDB2, FDO, FDH, FCE, UTA, UTG, BDH, BRD, BLD

Data

Русский (ru) -

SIL 2 Safety Assessment Certificate

Data

English

Request for Quotation

"*" indicates required fields