Product / VCS

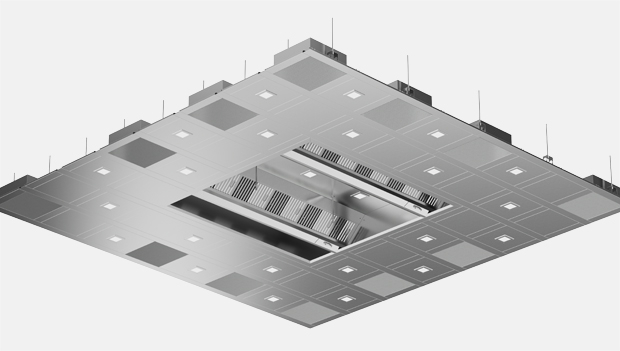

VCS – Ventilated Ceiling System (ETL)

Clean sightlines. Modular performance. A ceiling designed around your kitchen.

The Halton Ventilated Ceiling System (VCS) is ETL Listed and a fully integrated, architecturally clean solution for light‑ to medium‑duty commercial cooking environments. Designed for prestige projects, display kitchens, culinary schools, correctional facilities, and cook‑chill operations, the VCS delivers exceptional capture efficiency, comfort, and aesthetics in one unified ceiling.

How it works

The Halton Ventilated Ceiling System (VCS) is a fully integrated, architecturally clean solution for light‑ to medium‑duty commercial cooking environments. Designed for prestige projects, display kitchens, culinary schools, correctional facilities, and cook‑chill operations, the VCS delivers exceptional capture efficiency, comfort, and aesthetics in one unified ceiling plane.

Key Specifications

- Listing: ETL Listed

- Duty: Light to medium-duty cooking

- Ceiling height range: 84″ to 120″ AFF

- Exhaust airflow: 250–300 CFM per active linear foot

- Supply airflow (typical guidance): up to ~80% of exhaust volume (application dependent)

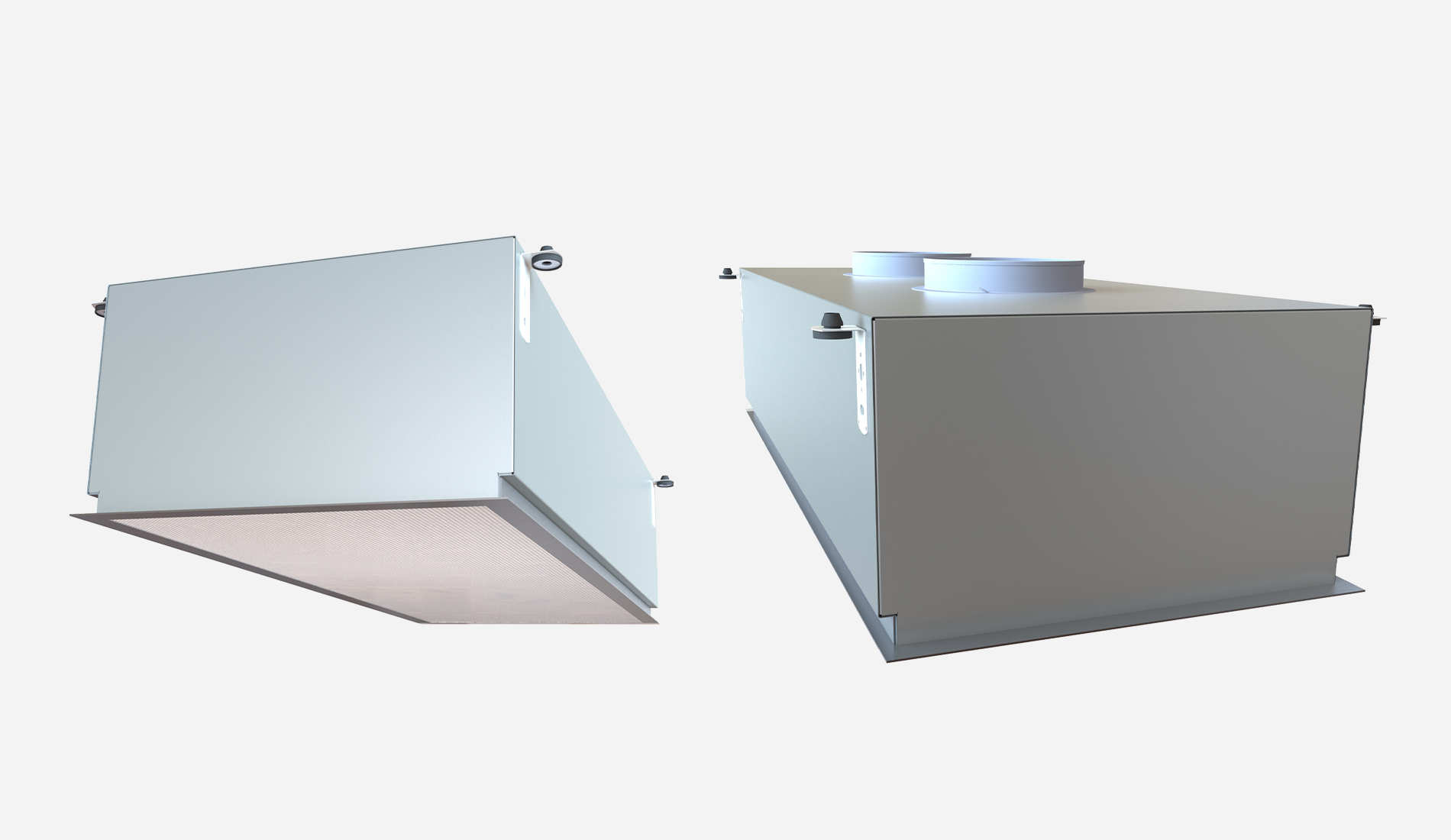

- Construction: stainless ceiling grid, pods, and cassettes

- Filtration: Halton KSA centrifugal extractors (removable, washable)

- Lighting: Integrated LED in exhaust pods; 50,000‑hour LED lifetime with matching power‑supply longevity

- Experience: Unobstructed sightlines

Why Choose a Ventilated Ceiling System?

The Ventilated Ceiling System replaces traditional canopy hoods with a flush, unobstructed ceiling plane that improves sightlines, enhances the dining experience, and simplifies cleaning. It is custom‑engineered for each project and adaptable to multiple appliance lineups and architectural layouts.

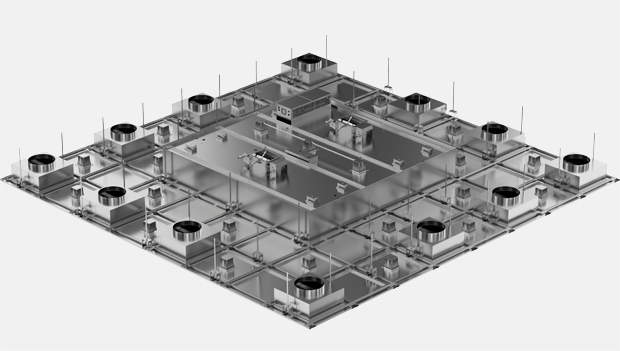

Adaptable Configurations for Modern Commercial Kitchen

Design Flexibility The VCS supports multiple kitchen layouts, including:

- Wall‑line appliance rows

- Back‑to‑back island configurations

- Single‑row island layouts with double V‑bank pods

Each configuration includes defined airflow rates, overhang requirements, and mounting heights to ensure proper capture and containment.

Optional Features & System Enhancements

The VCS can be tailored to meet project‑specific requirements through a range of optional integrations and finish choices, including:

- Select powder‑coated color finishes (consult factory for availability)

- Fully integrated fire‑suppression system

- Compatibility with the M.A.R.V.E.L. demand‑controlled kitchen ventilation platform

FAQs

Frequently Asked Questions

What is a ventilated ceiling system in a commercial kitchen?

A ventilated ceiling is a ceiling-integrated ventilation approach that combines exhaust, supply air, and lighting into a modular ceiling grid to support open sightlines and a clean architectural look.

What cooking duty is VCS designed for?

VCS is engineered for light to medium-duty cooking applications, with the final design configured to the specific kitchen and appliance line-up.

How high can the VCS ceiling be installed?

Halton guidance indicates the ceiling may be mounted 84″ to 120″ above finished floor (A.F.F.)

Can VCS work with demand-controlled ventilation?

Yes. VCS is compatible for use with Halton M.A.R.V.E.L. demand ventilation kitchen control.

Downloads

Contact Us

For inquiries, request a quotation or ask our specialists. We are here for you.

Our team looks forward to hearing from you. Please fill in the form. We’ll be in touch with you shortly.

"*" indicates required fields