Product / FDB2

Overview

- Type-approved by the most recognized classification societies: class A0 without insulation, A15-A60 when suitably insulated

- Shock and vibration tested

- Blades contain silicone seals (effective up to 300 ºC) for low leakage in normal conditions and thermal expansion graphite seals (effective from 150 ºC) to increase tightness even up to 50% in a case of fire

- A closed damper fulfils the requirement of leakage (EN1751:2014) from class 1 to class 3 depending on the size. Details available from Halton Marine

- Casing leakage (EN1751:2014) class B

- The nominal fuse release temperatures are 50 ºC, 74 ºC or 100 ºC. Other temperatures available

- Low weight due to patented double skin blade structure

- Automatic electrical, pneumatic or spring operation system available

- Maximum duct pressure for damper construction 5000 Pa and maximum air velocity 15 m/s

- The normal operating temperature for the damper is between -50 ºC to +80 ºC. Actuator and component selection can affect this temperature range. Other temperatures available on request

- Available as ATEX/IECEx certified

- SIL 2 safety assessment certificate available for the damper on specific terms

Specification

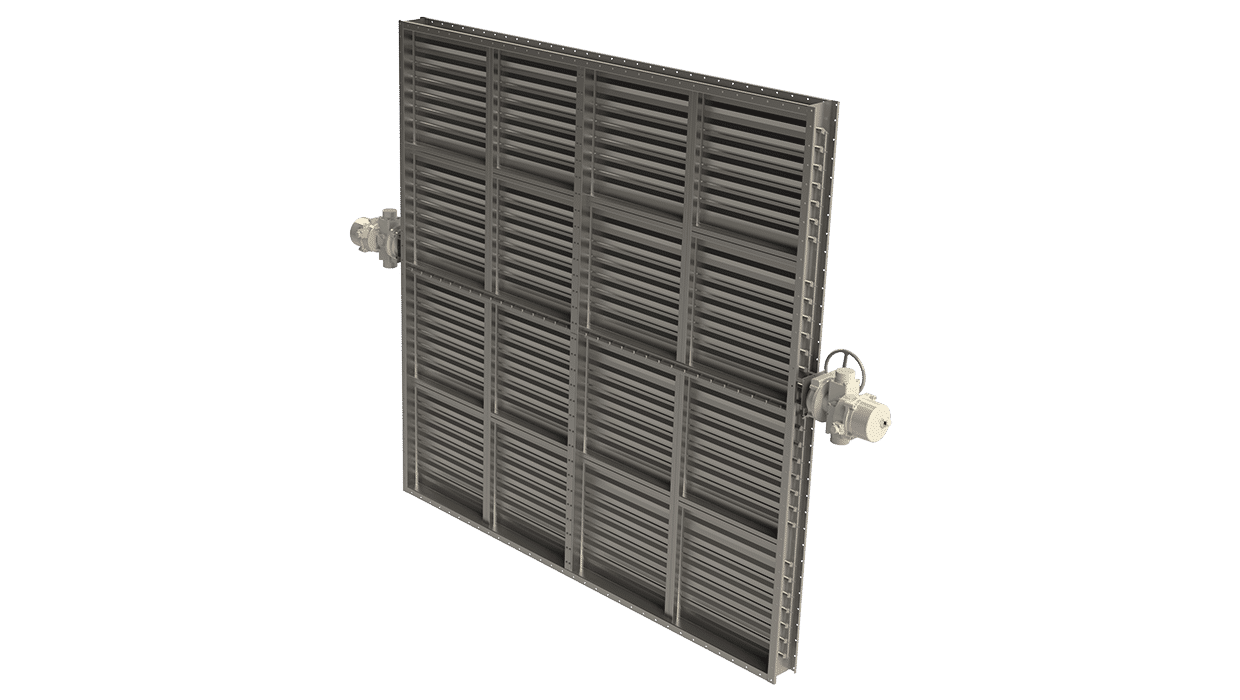

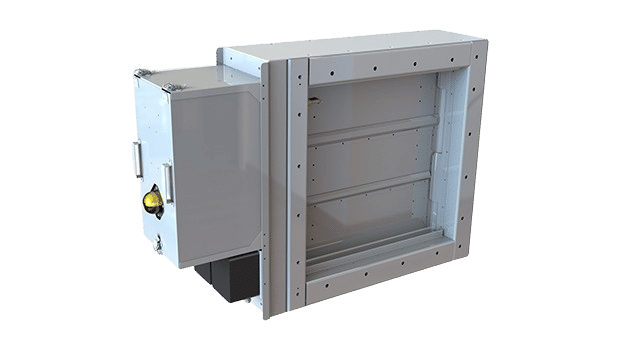

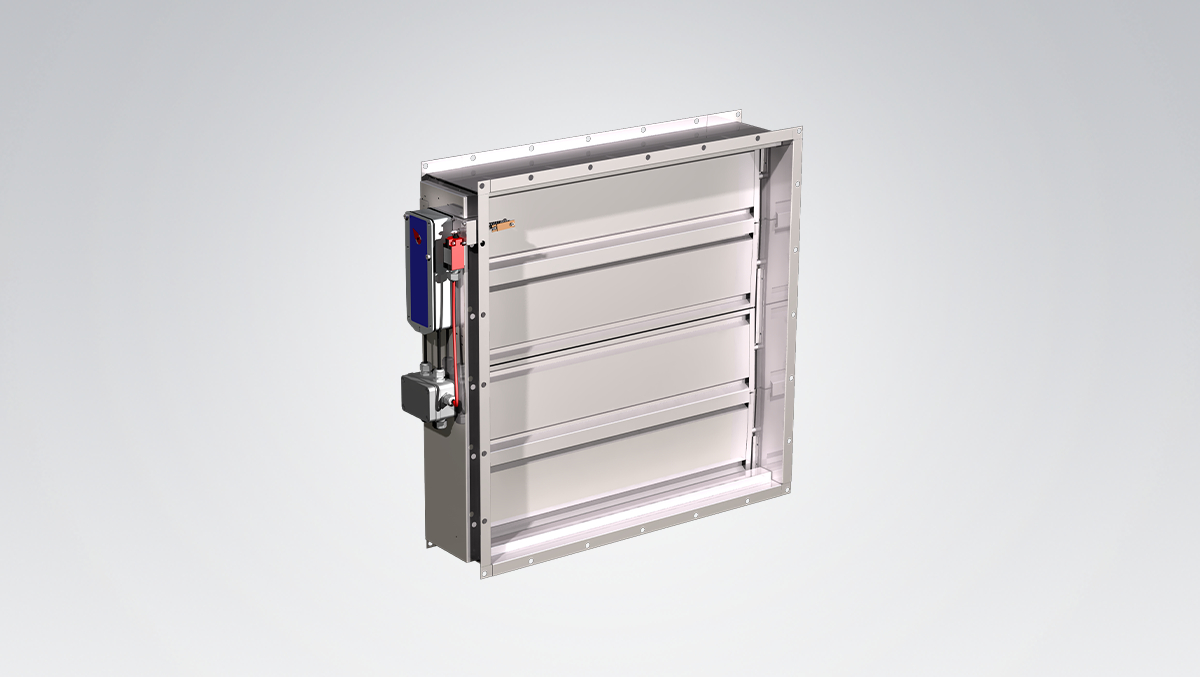

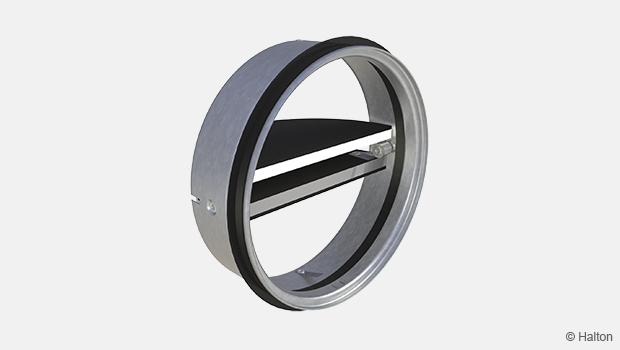

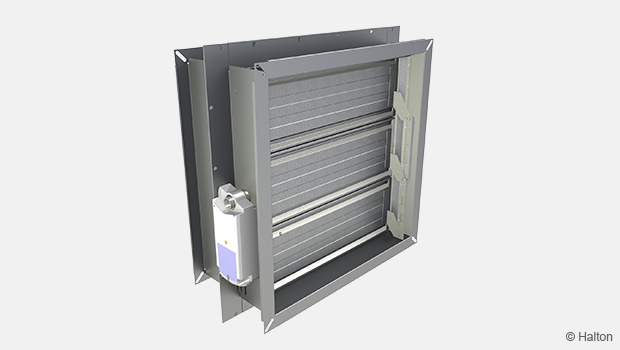

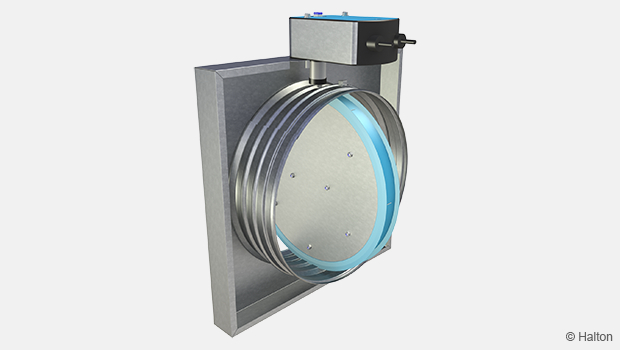

Halton FDB2 fire dampers are type-approved class A0(A60) fire and gas dampers for use in offshore, marine and navy ventilation systems. The FDB2 can be installed in rectangular or circular ducts. All fire dampers have a fusible link and they prevent the spread of fire and gases within the ventilation ductwork. When the blades are in the open position, the device does not cause significant pressure loss, noise or flow disturbance. Fire dampers are set from outside and can be installed in any position. An open-closed indicator is visible on the outside of the damper. Fire dampers with non-standard dimensions can be supplied on request.

Dimensions

FDB2 fire dampers meet international standards for both rectangular (width B 100-1200 mm and height H 100-1600 mm, 1 mm division) and circular ducts (Ø100-1250 mm). Modular constructions are available for bigger sizes. Non-standard dimensions and flange drilling available on request. Standard flange width 27 mm. Flanges and drilling also available according to ISO 15138 standards. Frame thickness 3 mm or 3-5 mm according to SOLAS. Also 6, 8 and 10 mm frame thicknesses are available on request. Blades are made of two sheets, each of them being 1 mm thick (sandwich design).

Frame thickness according to SOLAS

| DIMENSIONS | S |

| If B or H > 100, but < 449 | 3 |

| If B or H > 450 but < 649 | 4 |

| If B or H > 650 | 5 |

Frame thickness according to SOLAS, Edition Dec. 2015

| DIMENSIONS | S |

| If A < 0.075 m2 | 3 |

| If A > 0.075 and A < 0.45 m2 | 4 |

| If A > 0.45 m2 | 5 |

Actuator effect in dimensions

| ACTUATOR | R | A | |

| Electrical (EL) | BF230, BF24, BF120 | 100 | H<300 = 300, H>300 =H |

| Pneumatic (PNR) | Pneumatic rotating actuator AT100 | 170 | H<300 = 300, H>300 =H |

| Pneumatic (PNR) | Pneumatic rotating actuator AT200 | 190 | H<350 = 350, H>350 =H |

| Spring (SP) | Spring | 140 | H |

The above table contains only some examples of actuators and their effect on dimensions.

FDB2 general drawings

FDB2 circular connections

FDB2 general drawing, top

FDB2 general drawing, circular with connection flanges

| DAMPER HEIGHT | TOTAL DEPTH WITH BLADES OPEN |

| < 250 mm | 210 mm |

| > 250 mm < 300 mm | 250 mm |

| > 300 mm < 349 mm | 210 mm |

| > 350 mm | 240 mm |

Material and Finishing

| PART | MATERIAL | FINISHING |

| Frame | Carbon steel | Painted or galvanized |

| Frame | Stainless steel EN 1.4301 (AISI304), EN 1.4404 (AISI316L), EN 1.4432 (AISI316L) | – |

| Blades | Steel | Galvanized |

| Blades | Stainless steel EN 1.4301 (AISI304), EN 1.4404 (AISI316L), EN 1.4432 (AISI316L) | – |

| Maintenance-free bearings |

Stainless steel EN 1.4404 (AISI316L) | – |

| Shafts | Stainless steel EN 1.4404 (AISI316L) | – |

Product Models and Accessories

Halton FDB2 is available with following actuators:

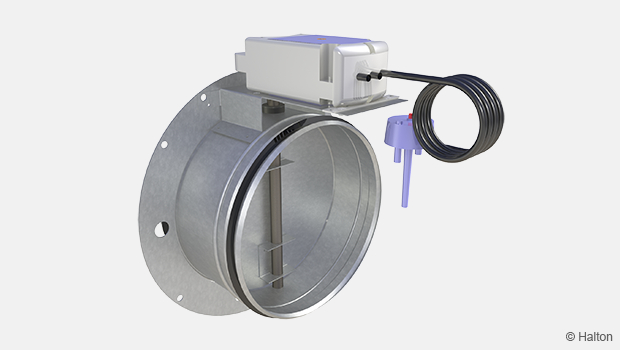

- FDB2-EL: Electrical spring return motor; standard actuators being 24 V or 230 V or 120 V. The motor contains built-in open-closed limit switches. Separate junction box included in the EL-model. A wide range of Ex actuators available, including a one second closing time function as an option.

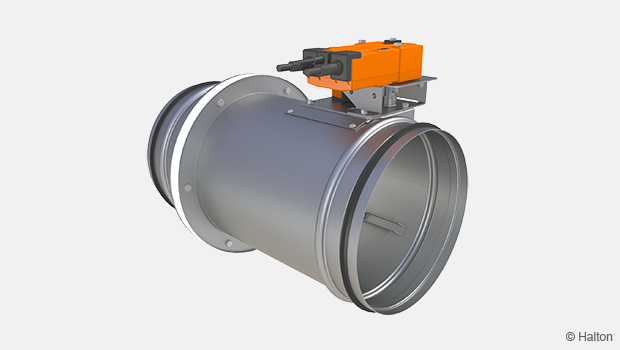

- FDB2-PNR: Pneumatic rotating actuator

- FDB2-SP: Manual spring-actuated damper with fusible link

DOT: manual override function available for PNR and EL models.

HSO: Halton Smart Override function for HVAC damper black-start available for PNR and EL models. With automatic reset function when power and/or pneumatic air supply is reinstated.

A wide range of accessories available.

Operation Principle

In the event of a temperature rise in ductwork:

- FDB2-EL: fusible link releases and cuts off operating voltage to the spring return motor, allowing the spring to close the damper blades. The fire damper opens automatically when the fuse has been changed and the operating voltage to the motor is re-established.

- FDB2-PNR: fusible link releases and cuts off operating pressure to the spring return actuator, allowing springs to close the damper blades. The fire damper opens automatically when the fuse has been changed and the pneumatic air supply is re-established.

- FDB2-SP: fusible link releases allowing the spring to close the damper blades. When the fuse has been changed, the fire damper must be reset into open position manually.

Weights

Weights of standard Halton Marine FDB2 dampers without an actuator (kg)

| H/HEIGHT (mm) |

B / WIDTH (mm) | |||||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | |

| 100 | 5 (5) | 7(7) | 9(9) | 10(10) | 12(13) | 14(15) | 15(22) | 17(25) | 19(27) | 20(30) | 22(32) | 24(35) |

| 200 | 7(7) | 9(9) | 11(11) | 12(12) | 14(16) | 16(18) | 18(26) | 20(28) | 22(31) | 23(34) | 25(36) | 27(39) |

| 300 | 9(9) | 11(11) | 13(13) | 15(15) | 17(19) | 19(21) | 21(30) | 23(32) | 25(35) | 27(38) | 29(41) | 31(43) |

| 400 | 11(11) | 13(13) | 15(15) | 17(17) | 20(22) | 22(24) | 24(33) | 26(36) | 28(39) | 30(42) | 32(45) | 34(48) |

| 500 | 13(16) | 16(19) | 18(22) | 21(25) | 23(27) | 25(30) | 28(38) | 30(41) | 32(44) | 35(47) | 37(50) | 39(54) |

| 600 | 15(18) | 18(21) | 20(24) | 23(27) | 25(30) | 28(33) | 30(41) | 33(45) | 35(48) | 38(51) | 40(55) | 43(58) |

| 700 | 18(25) | 21(28) | 23(32) | 26(35) | 29(39) | 32(42) | 34(46) | 37(50) | 40(53) | 42(57) | 45(60) | 48(64) |

| 800 | 20(27) | 23(31) | 25(35) | 28(38) | 31(42) | 34(46) | 37(50) | 40(53) | 43(57) | 46(61) | 49(64) | 51(68) |

| 900 | 22(31) | 25(35) | 28(39) | 32(42) | 35(46) | 38(50) | 41(54) | 44(58) | 47(62) | 50(66) | 53(70) | 56(74) |

| 1000 | 24(33) | 27(37) | 31(41) | 34(45) | 37(50) | 40(54) | 44(58) | 47(62) | 50(66) | 53(70) | 57(74) | 60(78) |

| 1100 | 26(36) | 30(41) | 33(45) | 37(49) | 40(54) | 44(58) | 47(62) | 51(67) | 54(71) | 58(75) | 61(79) | 65(84) |

| 1200 | 28(39) | 32(44) | 36(48) | 39(52) | 43(57) | 46(61) | 50(66) | 54(70) | 57(75) | 61(79) | 65(84) | 68(88) |

| 1300 | 31(42) | 35(47) | 38(52) | 42(56) | 46(61) | 50(66) | 54(70) | 58(75) | 62(80) | 65(84) | 69(89) | 73(94) |

| 1400 | 32(45) | 37(50) | 41(55) | 45(59) | 49(64) | 53(69) | 57(74) | 61(79) | 65(84) | 69(88) | 73(93) | 77(98) |

| 1500 | 35(48) | 39(53) | 43(58) | 48(63) | 52(68) | 53(73) | 60(78) | 65(83) | 69(89) | 73(94) | 77(99) | 82(104) |

| 1600 | 36(51) | 41(56) | 45(61) | 50(66) | 54(72) | 59(77) | 63(82) | 67(87) | 72(92) | 76(98) | 81(103) | 85(108) |

| D2 ØD | WEIGHT |

| (mm) | kg |

| 100 | 8 (8) |

| 125 | 8 (8) |

| 160 | 12 (12) |

| 200 | 13 (13) |

| 250 | 19 (19) |

| 315 | 20 (20) |

| 400 | 27 (27) |

| 500 | 35 (43) |

| 630 | 46 (62) |

| 800 | 62 (89) |

| 1000 | 83 (118) |

| 1250 | 113 (162) |

(Frame thickness according to SOLAS)

Examples of actuator weights: FDB2-EL GGA 326.1E 2,3 kg, GNA 326.1E 1,3 kg, BF230 +3,2 kg, BLF230 +1,7 kg, ExMax/Redmax +3,5 kg, CSQP +3 kg ,

FDB2-PNR AT100 +2,1 kg, AT100 as AISI316 4,4 kg, AT200 +3,2kg, AT200 as AISI316 +6,2 kg, FDB2-SP +1 kg. Control enclosure +4 kg.

Installation

Installation on wall or roof.

At wall installation the blade orientation must always be in horizontal plane.

Copies of Installation, Operation and maintenance manuals are available from Halton Marine Sales offices and distributors.

Product Code

(S)=Shape of Connection

(A) Circular on one side

(C ) Circular on two sides

(R) Rectangular

(W)=Width

100-1200

(H)=Height

100-1600

(D)=Diameter

100-1250

(FA)=Fire Approval

(C1) ABS American Bureau of Shipping

(C2) MED Marine Equipment Directive

(C3) LRS Lloyds Register

(C4) DNV-GL

(C5) BV Bureau Veritas

(C9) RMRS Russian Maritime Register

(EX)=Atex Class

(NA) No

(X1) ATEX certified damper [please fill]

(SF)=Flange Option

(H0) Eurovent flange in circular connections

(H1) Eurovent flange + loose flange in circular connections

(HA) Eurovent flanges

(HB) Eurovent flanges + counter flanges (2 sides)

(HC) Eurovent flanges + counter flange (1 side)

(N0) ISO15138 flange drilling in circular connection

(N1) ISO15138 flange drilling + Loose flange in circular connection

(NA) Circular connections without flanges

(NR) ISO15138 flange drilling

(FS)=Frame Dimensioning

(HS) Manual dimensioning

(SO) SOLAS dimensioning

(S1) SOLAS dimensioning (supplement 2015)

(MA)=Material

(AS) Stainless steel 1 mm EN1.4404

(CS) Carbon steel 1 mm

(LS) Stainless steel 1 mm EN1.4432

(SS) Stainless steel 1 mm EN1.4301

(FM)=Frame Material

(A3) Stainless steel 3 mm EN1.4404

(A4) Stainless steel 4 mm EN1.4404

(A5) Stainless steel 5 mm EN1.4404

(C3) Carbon steel 3 mm

(C4) Carbon steel 4 mm

(C5) Carbon steel 5 mm

(L3) Stainless steel 3 mm EN1.4432

(L4) Stainless steel 4 mm EN1.4432

(L5) Stainless steel 5 mm EN1.4432

(S3) Stainless steel 3 mm EN1.4301

(S4) Stainless steel 4 mm EN1.4301

(S5) Stainless steel 5 mm EN1.4301

(FI)=Finishing

(HG) Hot galvanized

(NA) Acid treatment

(PN) Standard painting grey RAL7001

(PX) Special Painting C5-M ISO12944

(IN)=Insulation

(N) No

(Y) A60 insulation on actuator side

(RE)=Actuator

(E1) Electric – Belimo, BF24-2-HL

(E3) Electric – Belimo, BF230-2-HL

(E7) Electric – Belimo, BF120-HL

(E8) Electric – Belimo, NF24A-SR

(E9) Electric – Belimo, NF24A-SR-S2

(E10) Electric – Belimo, SF24A-SR

(E11) Electric – Belimo, SF24A-SR-S2

(I1) InMax – Schischek, 15-SF

(I2) InMax – Schischek, 15-SF VAS

(I3) InMax – Schischek, 15-SF1 VAS

(I4) InMax – Schischek, 8-SF-1

(I6) InMax – Schischek, 15-SF-1

(I9) InMax – Schischek, 5.10-SF

(I10) InMax – Schischek, 5.10-SF VAS

(I11) InMax – Schischek, 8-SF-1 VAS

(K0) Electric – Belimo, BFN24.1

(K2) Electric – Belimo, BFN230.1

(P0) Pneumatic – Air Torque, AT101, Aluminium

(P3) Pneumatic – Air Torque, AT104, AISI316

(Q1) Pneumatic – Air Torque, AT201, Aluminium

(Q2) Pneumatic – Air Torque, AT204, AISI316

(S1) Spring

(T1) Electric – Belimo, BF24-T-2.1HL

(T3) Electric – Belimo, BF230-T-2.1HL

(Z2) Electric (EX) – Schischek, ExMax 15-SF

(Z3) Electric (EX) – Schischek, ExMax 5-10SF

(Z4) Electric (EX), Schischek, ExMax 15-SF VAS

(Z5) Electric (EX) – Schischek, ExMax 15-SF1 VAS

(Z6) Electric (EX) – Schischek, ExMax 8-SF1

(Z7) Electric (EX) – Schischek, ExMax 15-SF1

(Z10) Electric (EX) – Schischek, ExMax 5.10-SF VAS

(Z11) Electric (EX) – Schischek, ExMax 8-SF1 VAS

(C1) Electric – Elodrive, CSQP-05A1E 24V

(C2) Electric – Elodrive, CSQP-05A2E 120/230V

(C3) Electric – Elodrive, CSQP-10A1E 24V

(C4) Electric – Elodrive, CSQP-10A2E 120/230V

(C5) Electric – Elodrive, CSQP-15A1E 24V – Blocked

(C6) Electric – Elodrive, CSQP-15A2E 120/230V – Blocked

(FU)=Fuse

144 °C

100 °C

95 °C

74 °C

72 °C

70 °C

65 °C

50 °C

(AC)=Accessories

(E1) Junction box – Ensto, Plastic, IP66 & 67

(E2) EX junction box – Cooper, GRP, IP66, T6

(E4) Cable connectors – Wieland & Hensel

(L2) Limit switch 2 pcs – Bernstein, Plastic, IP66, Mechanical

(L4) EX Limit switch 2 pcs – Bartec, Plastic, IP66, Mechanical

(L5) EX Limit switch 4 pcs – Bartec, Plastic, IP66, Mechanical

(L6) EX Magnetic switch 2 pcs – Elobau, AISI6118, Magnetic

(L7) EX Magnetic switch 4 pcs – Elobau, AISI6118, Magnetic

(L8) EX Magnetic switch 2 pcs – Pepperl & Fuchs, AISI303, Inductive

(L9) EX Magnetic switch 4 pcs – Pepperl & Fuchs, AISI303, Inductive

(M1) Solenoid valve – SMC, Aluminium, 24 VDC

(M2) Solenoid valve – SMC, Aluminium, 230 VAC

(M3) EX solenoid valve – ASCO, Brass, 24 VDC

(M4) EX solenoid valve – ASCO, Brass, 230 VAC

(M5) EX solenoid valve – Bifold, AISI316, 24 VDC

(P1) Manual pneumatic valve – SMC, Aluminium

(P2) Manual pneumatic valve – Bifold, AISI316

(S3) Limit switch open/Close – Belimo, SN2, Mechanical

(SC) Cover box – Stainless steel

(ST) Pneumatic tubing & fittings – AISI316

(ED) Manual over-ride handle – Halton DOT or HV-SKU

(O1) Smart override handle – Halton, HSO Schischek

(O2) Smart override handle – Halton, HSO Pneumatic

Code example

FD3/R-1300-1200,FA=C1,SF=HA,FS=SO,MA=CS,FM=C5,FI=HG,RE=Z2,FU=50,ZT=N,AC=E2

Downloads

-

Halton FDB2 datasheet 2025

Data

English -

ABS Certificate for Halton FDB2

Data

English -

BV Certificate for Halton FDB2

Data

English -

CCS Certificate for Halton FDB2

Data

简体中文 (zh) -

DNV Certificate for Halton FDB2

Data

English -

EAC Certificate for Halton FDA, FDB2, FDO, FDH, FCE, UTA, UTG, BDH, BRD, BLD

Data

Русский (ru) -

EC Type Examination Certificate for Halton FDB2

Data

English -

RMRS Certificate for Halton FDB2

Data

Русский (ru) -

TR CU – SAFE Certificate for Halton FDB2, FDL, FEX, UTG, UTX, UTP, UTN, UTT, BLD, BRD

Data

Русский (ru) -

LR Certificate for Halton FDB2

Data

English -

Halton Marine Oy MED Quality System Module D Certificate

Data

English -

SIL 2 Safety Assessment Certificate

Data

English -

ATEX Certificare for FDB2, FDL, FDO, FDA

Data

English -

ClassNK Certificate for Halton FDB2

Data

English

Request for Quotation

"*" indicates required fields