In day-to-day operations of a hotel’s Chinese kitchen, cooking grease remains a persistent challenge. High-heat cooking methods like wok-frying and deep-frying generate immense volumes of grease vapor and particulate matter. Traditional hoods often prove ineffective, leading to significant grease buildup within ducts over time. This not only necessitates frequent and costly cleaning but also poses a serious fire safety hazard.

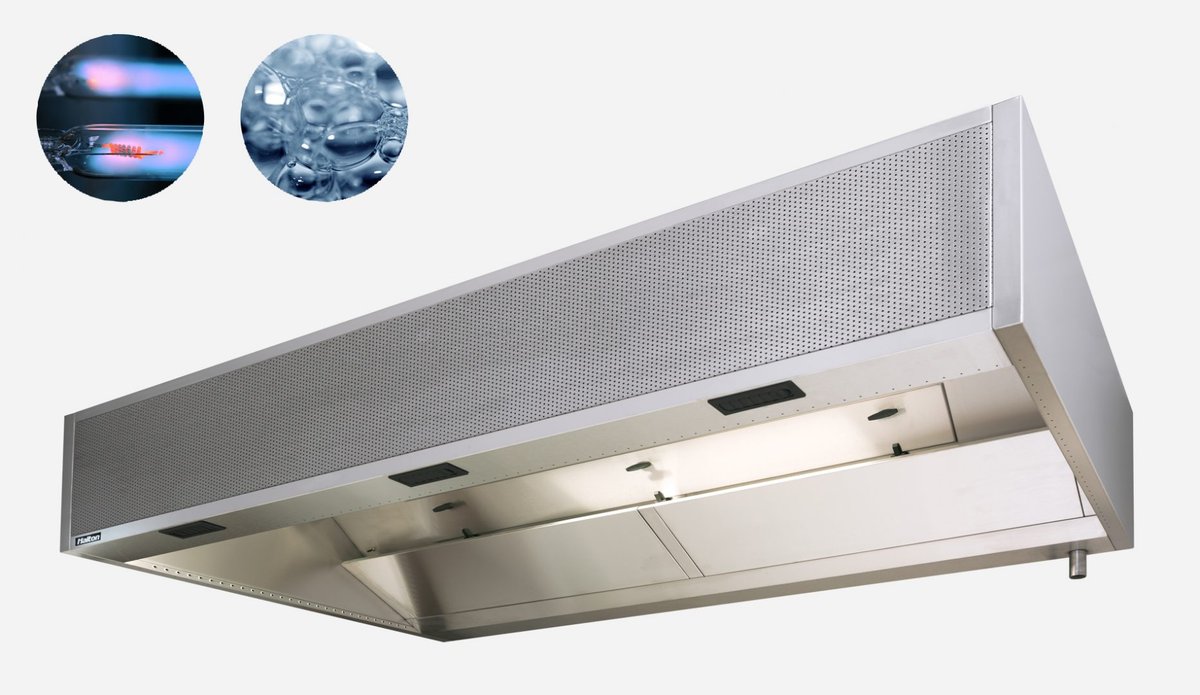

Engineered specifically to address these pain points, Halton UWF Hood is ideal for all enclosed or open kitchen layouts within hotels. It features Capture RayTM and water-wash technologies, offering an ideal solution to the unique demands of Chinese culinary operations.

Grease and Energy Reduction Through Innovative Technology

The core advantage of UWF lies in its innovative use of the Capture RayTM technology. This technology neutralizes the small grease particles, the grease vapors and a portion of the VOCs that can’t be removed by any primary mechanical filtration, preventing residue buildup in the exhaust plenums and ductwork. By reducing grease accumulation, the Capture RayTM technology significantly reduces the odors discharged outdoor and thus lowers the kitchens’ environmental impact on the neighborhood and the risk of complaints or legal action.

Moreover, UWF incorporates the Capture Jet™ technology which is based on the use of one or several sets of aerodynamic nozzles. Compared to conventional exhaust hoods, it reduces required exhaust airflow by 30–40%, resulting in significant energy savings. At the same time, the system delivers a gentle supply of fresh air into the kitchen, maintaining balanced air pressure and ensuring a comfortable cooking environment free from disruptive drafts.

Reduced Maintenance with Integrated Water Wash

Halton UWF exhaust hood’s integrated water wash technology streamlines operations in hotel kitchens by fully automating filter cleaning. It significantly reduces the need for manual handling, cutting labor costs and freeing staff from routine maintenance. It ensures consistent hygiene and fire safety while reducing dependence on external service providers.

In large kitchens with extended operating hours, these benefits are particularly evident. With filter maintenance efficiently managed, your culinary team can focus entirely on their core task: preparing high-quality meals for guests.

UV on demand

Halton’s integrated Thermal Imaging sensor (HTI) continuously monitors cooking surfaces to detect whether appliances are off, idling, or actively in use. This enables the “UV On Demand” technology to activate UV lamps exclusively during cooking mode—rather than continuously whenever the fan is running. This responsible approach extends the service life of UV-C lamps, significantly reducing replacement frequency and maintenance costs while lowering energy consumption. As a result, up to half of all UV-C lamp sets can be saved, delivering measurable savings in both maintenance and energy expenses.

For Chinese wok kitchens in hotels where efficiency, energy conservation, and operational safety are critical, Halton UWF provides value that goes beyond immediate grease issues. By pairing Capture Ray™ technology with automated water wash systems, our solution directly addresses the essential needs of a hotel’s wok kitchen. It delivers what matters most: reduced long-term costs, lower risks, and greater efficiency.

To learn more about our innovative technologies for hotel kitchens, explore our solutions here.