Tunnel Ventilation

Tunnel ventilation ensures safe air quality for users and, in emergencies, controls smoke to support safe evacuation. Because these systems consume high energy, efficiency in design and operation is essential.

Operating in the most arduous conditions and extremes of climate, Halton dampers have a proven record of reliability and high performance in operational service Fire and Smoke Dampers form an important part of the ventilation system and are installed primarily to prevent the spread of fire or smoke in the event of a fire. The selection of proven certified dampers is essential to ensure the high level of safety required in today’s

transport ventilation systems. Halton has a depth of experience over many years in the design and manufacture of dampers for the tunnel and metro industry.

This has resulted in the company establishing a comprehensive data base of “know-how” covering operating performance, levels of system safety and installation criteria as well as mean time between failure data. Extensive industry experience ensures that Halton is highly competent in the application of its products and services.

Safety of the general public is of prime consideration for operators of transport systems and for consultants and contractors alike. Halton has extensive experience in the application of dampers in tunnel and metro systems.

Station & high-temperature operation tunnel dampers and fire dampers supplied to following projects

Contract

Heathrow Express

Limehouse Link

Rotherhithe

Heathrow

Norther Line Extension

Crossrail

Bell Common Tunnel M25

Holmesdale Tunnel M25

London Power Cable Tunnels

Thames Tideway Tunnel

Frejus Tunnel

Ankara Metro

Istanbul Metro

TAG Tunnel

Sydney Eastern

TRUPO

Bung Dang

Changwan

Backdal

RATP

Cointe

Athens Metro

Hofberg

Farchant

Airport Express

Central Station

Tai Lam

Taites Cairns

Discovery Bay

Quarry Bay

Lantau and Airport Railway

West Rail

Bangkok Metro

Tseun Kwan O

West Rail

Mont Blanc

Chamoise

Tunnel du Siaix

Tunnel de Foix

A86 Auto Route Paris

Paris A1 Road Tunnel

Monaco Tunnel

Riyadh Metro

Country

U.K.

U.K.

U.K.

U.K.

U.K.

U.K.

U.K.

U.K.

U.K.

U.K.

Italy

Turkey

Turkey

Turkey

Australia

Taiwan

Korea

Korea

Korea

France

Belgium

Greece

Germany

Germany

Hong Kong

Hong Kong

Hong Kong

Hong Kong

Hong Kong

Hong Kong

Hong Kong

Hong Kong

Thailand

Hong Kong

Hong Kong

France

France

France

France

France

France

France

Saudi Arabia

Application

Rail/Metro

Road Tunnel

Road Tunnel

Cargo Tunnel

Metro

Metro

Road

Road

Other

Other

Road Tunnel

Metro

Metro

Road Tunnel

Road Tunnel

Rail

Road Tunnel

Road Tunnel

Road Tunnel

Metro

Road Tunnel

Metro

Road Tunnel

Road Tunnel

Metro

Metro

Road Tunnel

Road Tunnel

Road Tunnel

Road Tunnel

Metro

Metro

Metro

Metro

Metro

Road Tunnel

Road Tunnel

Road Tunnel

Road Tunnel

Road Tunnel

Road Tunnel

Rail Tunnel

Metro

Halton dampers for tunnel projects

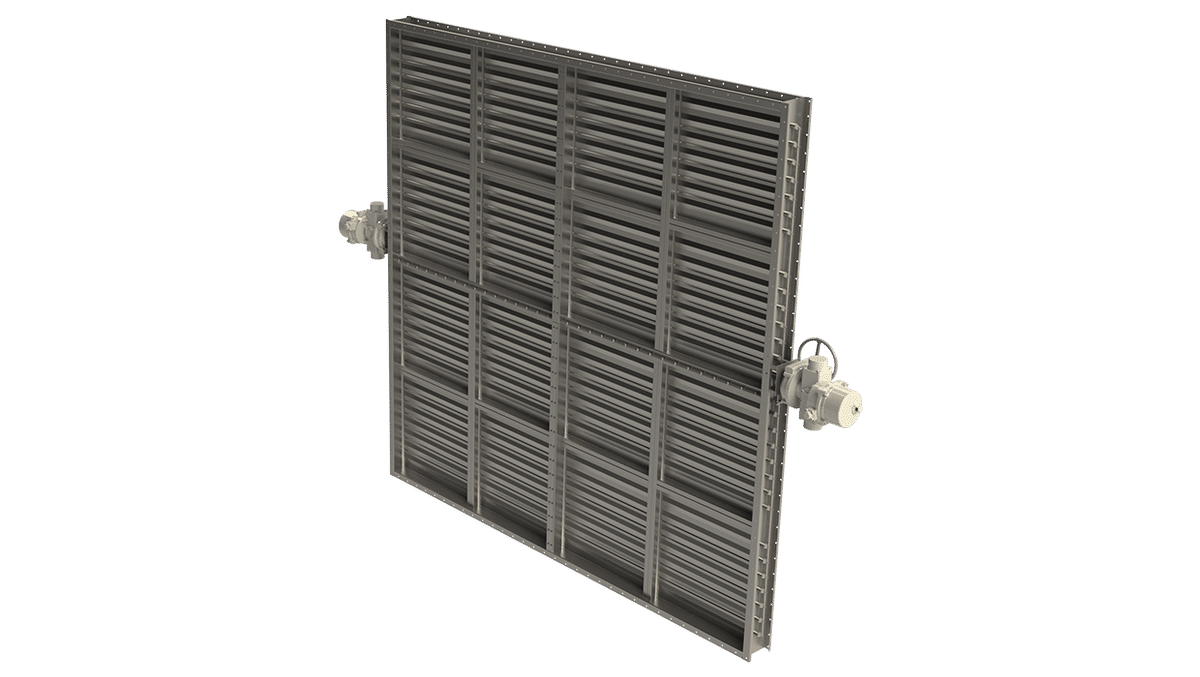

CFD-02TM – High temperature tunnel damper

- Maintains integrity and closure during and after tunnel fires, ensuring effective smoke containment and occupant safety is preserved in critical conditions.

- Performs reliably under pressure surges caused by passing trains, so that airflow performance remains stable during high-impact events.

- Delivers long-term durability, so that operational downtime is minimised and lifecycle reliability is assured.

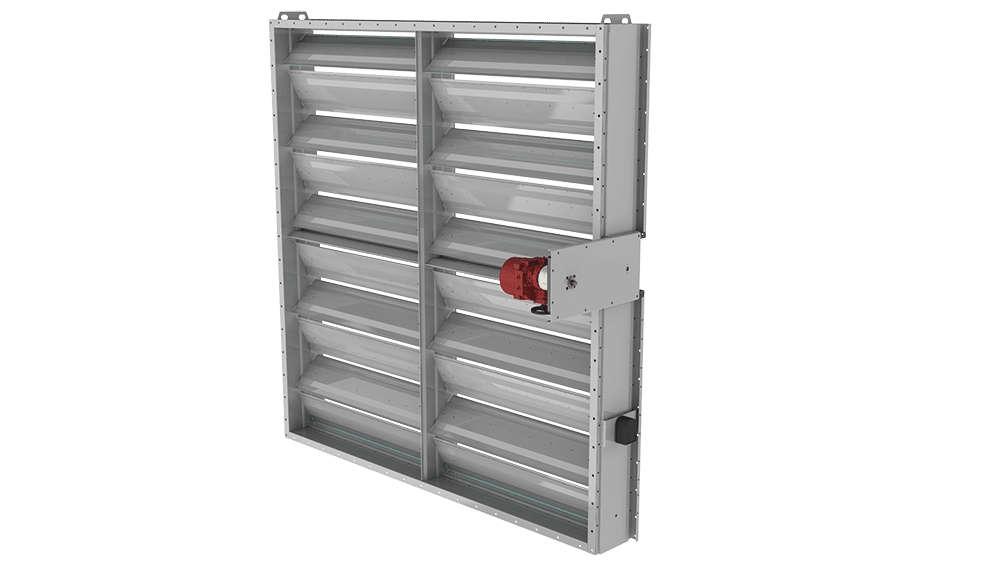

TDH – Tunnel damper – under development

- Operates reliably in high-temperature tunnel fire conditions, so that smoke control and compartmentation are maintained when it matters.

- Provides low leakage in normal and high temperature conditions, maintaining effective ventilation systems under stress.

- Modular assembly design enabling simplified maintenance and reduced-cost servicing.

UPE – Under platform extract grille

- Robust construction ensures the grille maintains alignment and structural integrity in demanding industrial environments.

- Flexible mounting options, reducing installation complexity.

- Dependable airflow without the need for powered actuation.

CPR-01/2H – Fire resistant pressure-relief damper

- Controlled pressure relief with minimal leakage, ensuring compliance with safety and ventilation standards.

- Provides reliable protection in critical fire scenarios. Helping contain fire and smoke within designated zones.

- Flexible and scalable installation, suitable for a variety of duct sizes and structural configurations.

Read more

How to convince a customer: test your product a million times

Tunnel dampers must be custom-made to the millimeter to fit any layout. Brutal testing in 400–1000 degrees Celsius ensures reliable operation. When it comes to budget, transportation cost of heavy-duty tunnel dampers can be a surprise – pleasant or unpleasant!

Ensuring fire safety is imperative in designing large tunnels. The reasons are obvious. In an underground space, the spreading of heat, smoke, and toxic gases can be catastrophic if proper precautions are not planned. Tunnel dampers are among the most essential fire safety equipment. No large tunnel is built without them.

In the past, hard lessons have been learned in various tunnel fire accidents. A major turning point was the London metro fire in 1987. After this incident, tunnel designers have paid much more attention to fire safety. Indeed, a huge leap in positive progress has been made.

Tunnel dampers can be divided into two groups (that may overlap to some extent). Their structure is similar: steel blades are attached to a rectangular frame, opening and closing with actuators. Both damper types are installed in ventilation ducts.

- Fire dampers automatically close in the event of a fire, sealing off the duct. This prevents the flames from spreading through the ductwork and protects the occupants and emergency responders.

- Smoke dampers control the spreading of smoke and hazardous gases. They can be used to isolate the area affected by smoke. Sometimes, by contrast, dampers are opened in specially designed ventilation shafts so that the ventilation system can extract the smoke away from the incident area.

By becoming a 100 percent shareholder in the damper manufacturer Flamgard Calidair in 2023, Halton took a strong foothold in the underground fire safety business.

“Our competitive edge lies in the thoroughly tested, tailor-made equipment that are often designed together with the customer,” says Lee Bramald, Business Development Executive at Halton.

Burning needs

The dampers are tested in large furnaces with temperatures of 400–1000 degrees Celsius and air pressure of up to 6000 pascals or more. This ensures reliability in real-life situations. A typical test can include, for example, opening and closing the steel blades every 10 minutes for two hours using the specialized actuators.

“One particularly demanding client wanted us to test a damper for 100,000 cycles. This is five times more than normally. We managed to do that. After tweaking the product further, we took it to a full million cycles. I got the impression we did convince the customer!”, says Lee Bramald.

Intensive, months-long testing periods guarantee that the actuators, bearings, seals, and other critical parts are reliable in any circumstances. Testing also ensures that dampers comply with international fire safety standards such as BS 476 and UL 555.

Power optimization by design

Ventilation technology is always inherently tied to energy efficiency, and tunnel dampers are no exception. When the parts of the damper allow the air to flow as smoothly as possible, less electricity is needed in the fans, and they can be smaller in size. This kind of energy optimization can make a big difference during the lifespan of the ventilation system.

Every tunnel project is unique, and ventilation equipment need to fit the desired airflow requirements smoothly. One size does not fit all. To meet the flexibility needs, the Halton-Flamgard dampers are manufactured by one-millimeter increments which ensures desirable fit for any layout. Actuators can also be positioned in a bespoke manner, adding further adaptability.

“When it comes to cost, we have an ace up our sleeve. Halton has factories around the world. This means the transportation costs will probably remain reasonable, wherever the customer project may be located on this planet. In a large tunnel project, hundreds of heavy-duty dampers are needed. If the manufacturer is far from the construction site, the transportation can cost a seven-figure sum,” Lee explains.

About testing

Testing details

- Damper operation at high temperature

- Leakage through the damper

- Mechanical resistance?

- Operation at specific pressure differentials

- Speed of operation

- Operational life cycles

Mechanical Tests

- 1000 operations at a pressure differential of 1200 Pa and 2500 Pa

- Time for damper to close is no more than 15 seconds

- Structural integrity of the dampers is measured at a pressure differential of 1000 Pa and 4000 Pa

- Leakage – damper subjected to pressure differentials of between 500 Pa and 4000 Pa in 500 Pa increments. Leakage no greater than 0.02m3/s/m2

- Temperature tested up to 400oC for 2hrs and 600oC for 1 hr

Halton Tunnel Dampers are tested rigorously

- Dampers tested in both vertical and horizontal orientations

- High temperature testing to 400oC for 2 hours, cycled every 10 minutes.

- CFD-02-TM additionally tested to UL 555 & BS 476 Pt 20, for 2 hrs at over 1,000oC, UL hose stream tested in accordance with ASTM E2226 15b.

- Testing with repetitive loading of the blades to 6,000 Pa x 7.8 million cycles

- Stress analysis of the blades and casing.

- 100,000 cycle durability testing

- Leakage testing in accordance with EN1751:2014 to Class 3 for blades and Class C for casing, including with forced blade deflection and case twist scenarios.