Product / MRV-ETL

MRV – M.A.R.V.E.L. DCKV Demand Controlled Kitchen Ventilation (ETL)

Demand Controlled Ventilation (DCKV) for Commercial Kitchens

ETL Listed – The M.A.R.V.E.L. demand controlled kitchen ventilation (DCKV) system is packed full of technological innovations. This is the first truly intelligent, responsive, and completely flexible demand controlled kitchen ventilation (DCKV) system specifically designed for commercial kitchen ventilation

M.A.R.V.E.L., in combination with Capture Jet™ technology, offers the lowest levels of energy consumption currently possible and provides complete comfort for users.

Overview

M.A.R.V.E.L.(1) is the first truly intelligent and responsive Demand Controlled Kitchen Ventilation system (DCKV).

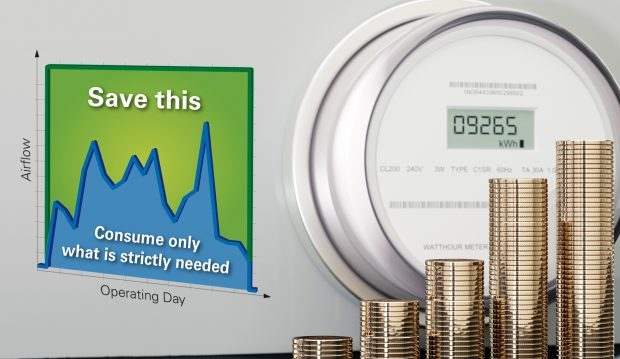

M.A.R.V.E.L. « scans » the cooking equipment’s surface to determine the appliances’ status: switched off, idle, or in the process of cooking. Each status corresponds to a different exhaust airflow need. The maximum value is used only in cooking mode for a limited time period. This leads to a first drastic reduction of exhaust airflows.

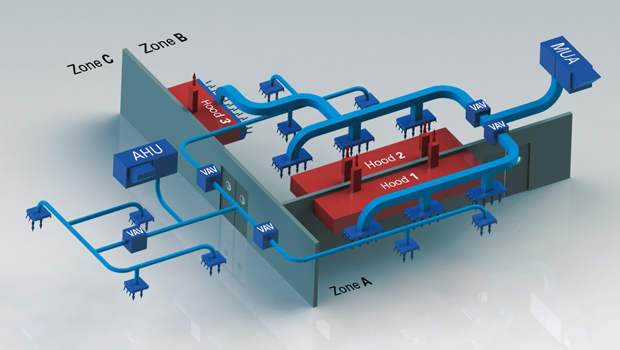

M.A.R.V.E.L. can uniquely adjust the exhaust airflow hood by hood in a fully independent way. If just one cooking range is operating, only the airflow for that hood concerned will be automatically adjusted. The other hoods will continue to operate at a low flow rate. It works the same way with the zones of a ventilated ceiling. This ability further reduces exhaust airflows.

The icing on the cake: M.A.R.V.E.L. continually regulates the speed of the fans to obtain the required rate with minimal pressure. Power consumption is thus kept to the bare minimum.

M.A.R.V.E.L. currently represents the most efficient Demand Controlled Kitchen Ventilation system with massive financial savings on air conditioning and on the electrical consumption of the fans.

Related Articles

Demand Controlled Kitchen Ventilation Systems Sensors, how do they differ, and how are they the same?

Demand Controlled Kitchen Ventilation Systems Sensors, how do they differ, and how are they the same?

Downloads

Contact Us

For inquiries, request a quotation or ask our specialists. We are here for you.

Our team looks forward to hearing from you. Please fill in the form. We’ll be in touch with you shortly.

"*" indicates required fields