Product / MRV

MRV – M.A.R.V.E.L. energy saving technology (CE)

Main features

◦ For commercial kitchens ◦ Massive energy savings on HVAC equipment ◦ Automated savings reports ◦ Best balance with Indoor Environment Quality ◦ Integrated fire prevention feature ◦ Optimized ROIs ◦ CE marked

Main benefits

- Halton Thermal Imaging sensing technology

- Smart and self-balanced

- Multiple zones control

- Optional Halton AirWatch IEQ sensor to combine optimal savings and air quality

Overview

Applications

M.A.R.V.E.L. is a Demand Controlled Ventilation (DCV) system specifically designed to drastically reduce the exhaust airflow rates in commercial kitchens – whether they are equipped with hoods, ventilated ceilings, or a combination of both.

By optimizing airflow in real time based on actual cooking activity, M.A.R.V.E.L. significantly lowers energy consumption related to kitchen ventilation, while ensuring optimal working conditions for staff and enhancing fire safety.

M.A.R.V.E.L. can be used in all types of kitchens – closed, opened, or show kitchens – and in general, all food-production environments. It is an asset for projects subjected to LEED (1), BREEAM (2), DGNB (3), RE2020 (4), or similar.

Description

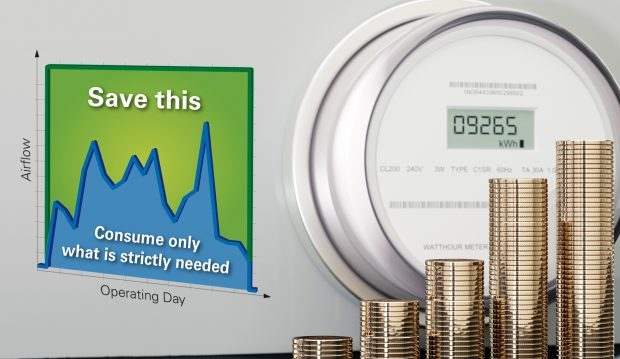

With an annual energy consumption of 800 TWh/m² (7), the foodservice industry is the highest energy-consuming sector among all commercial and residential buildings in the United States.

HVAC systems typically account for 40 to 60% of a restaurant’s energy bill. That’s as much as 320 to 480 TWh/m² in energy use.

Kitchen ventilation alone can consume as much energy as the cooking equipment itself. This is a widely observed trend across the industry. It also highlights a major opportunity for energy savings — provided ventilation is intelligently managed and optimized.

Considerable energy savings

- Up to 44%+ additional reduction in exhaust airflow thanks to M.A.R.V.E.L. optimization. This comes on top of the savings already achieved by the Capture Jet™ technology integrated into Halton hoods and ventilated ceilings.

- When factoring in a 35% reduction provided by Capture Jet™, the total exhaust airflow reduction can reach up to 64%.

- Less extracted air means less supply air is needed – air that must otherwise be heated in winter or cooled in summer.

- On that point, the rule is simple: a 64% reduction in airflow equals a 64% saving on the energy bill for heating or cooling the makeup air.

- M.A.R.V.E.L. also features an advanced algorithm for controlling exhaust fan speed. It adjusts both airflow and pressure, rather than maintaining constant pressure – whether it’s a simple exhaust fan or a pollution control unit like PolluStop.

- This ensures the fan always operates at the lowest possible speed. This significantly reduces noise levels in the kitchen.

- It especially delivers substantial electricity savings for the exhaust fans, both in transporting air and overcoming the filtration stages of pollution control units.

- These savings come in addition to the energy savings achieved on heating and cooling.

- The end result is unparalleled energy and cost savings compared to all other demand-controlled ventilation (DCV) systems.

How does M.A.R.V.E.L. reduce exhaust airflow so effectively?

- M.A.R.V.E.L. features the Halton Thermal Imaging Sensor. It continuously monitors the surface temperature of cooking appliances for variations linked to cooking activity – directly at the source and without delay.

- The M.A.R.V.E.L. algorithm then cross-references this activity data with an assessment of the heat loads generated by the cooking appliances.

- Exhaust airflow can then be continuously and accurately adjusted across three levels – appliances off, hot/standby, or cooking. It ensures optimal performance at all times.

- M.A.R.V.E.L. settings are fully configurable to accurately adapt to the layout of cooking blocks, regardless of the type of cooking appliances.

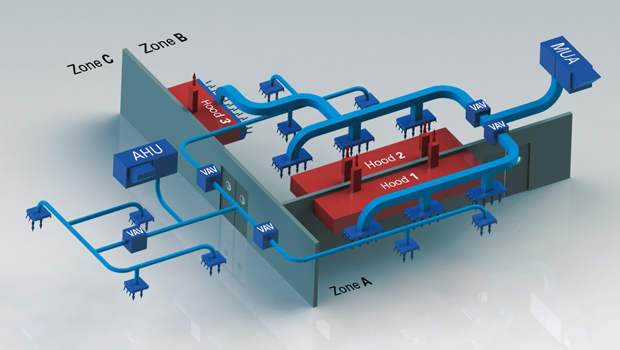

- Each hood section is equipped with an ABD (Automatic Balancing Damper), allowing exhaust levels to be adjusted independently for each section.

- For example, if a kitchen has 10 hood sections and only one is in use, only the airflow for that active hood will increase. The others remain at their minimum flow rate.

- The same logic is applied to each of the zones/subdivisions that make up a ventilated ceiling.

Halton Connect™ and Automated Energy Reports

- Actual airflow data measured by M.A.R.V.E.L. is automatically transmitted to the Halton Connect™ IoT (Internet of Things) platform.

- This data is processed to generate monthly reports detailing the energy savings achieved by M.A.R.V.E.L.

- The reports support energy-efficiency and sustainability goals with concrete data.

Optimized ROIs

- M.A.R.V.E.L. is a fully modular platform, with components that can be selected and combined based on requirements. It enables simplified configurations for small kitchens and advanced setups for larger ones.

- This approach maintains performance levels while optimizing return on investment (ROI).

Optimal Indoor Environement Quality

- By continuously adjusting airflow downward and keeping fan speed to a minimum, overall ventilation noise – including peak levels – is significantly reduced. Peak levels are only reached during brief rush periods.

- The optional Halton AirWatch sensor ensures that energy savings are not made at the expense of Indoor Environmental Quality.

- Halton AirWatch helps maintain optimal working conditions, staff wellbeing, and productivity.

- It includes safety loops for the most critical pollutants generated by kitchen processes or ventilation malfunction, thereby also enhancing overall safety.

Additional Fire Prevention Feature

- Choosing M.A.R.V.E.L. provides access to Halton FireWatch technology.

- Halton FireWatch detects thermal anomalies that may signal potential fire hazards and alerts staff to take preventive action.

- This proactive feature complements mandatory fire suppression systems, enhancing overall fire safety.

- It also helps prevent costly shutdowns and revenue losses caused by false activations of the fire suppression system.

- Additionally, Halton FireWatch may contribute to reduced insurance premiums.

Other benefits and features

- Compatible with all Capture Jet™ hoods, ventilated ceilings, Jet Extraction Systems, and Halton Air Handling Units.

- Supports the most complex kitchen configurations by independently controlling up to 4 exhaust fans and up to 12 zones with individual temperature and CO₂ monitoring, or up to 4 zones with IEQ monitoring.

- Coordinates supply VAV boxes to consistently maintain proper air balance.

- Equipped with the Halton Connect IoT platform, offering advanced 24/7 remote monitoring capabilities.

- Maximizes ownership value through Halton Connect & Care smart services, available as an option from kitchen commissioning.

- Provides multiple options for fire alarm management and integration with Building Management Systems (BMS).

- Complete solution—exhaust, supply, and VAV boxes—from a single supplier with comprehensive control.

- Fully self-balancing system that eliminates time-consuming manual balancing.

About MA.R.V.E.L. MaaS

M.A.R.V.E.L. as a Service (MaaS) is an all-inclusive “savings-as-a-service” offer. It consists of supplying Halton Capture Jet™ hoods or ventilated ceilings equipped with the M.A.R.V.E.L. system, at an investment level comparable to standard systems without M.A.R.V.E.L..

The service is based on a monthly fee, representing a fair share of the actual energy savings achieved. This model enables immediate operational savings on kitchen ventilation, while preserving capital expenditure.

- Controlled Capex.

- Immediate Opex reduction.

- Transparent performance monitoring.

- All inclusive predictive maintenance.

- Predictable and sustainably reduced operating costs.

Further information is available through Halton representatives.

About MA.R.V.E.L. ready option

The M.A.R.V.E.L.-Ready configuration includes factory-installed components that become difficult to access after the installation of hoods or ventilated ceilings. This setup facilitates future upgrades, especially when upfront capital expenditure is limited.

This option typically involves delivering the hoods with Automated Balancing Dampers (ABDs) pre-installed and preparing them for future integration with M.A.R.V.E.L. controls.

(1) LEED – Leadership in Energy and Environmental Design (2) BREEAM – Building Research Establishment Environmental Assessment Method (3) DGNB – German Sustainable Building Council (4) RE2020 – French Environmental Regulation 2020 (5) EN 16282-2 Equipment for commercial kitchens – Components for ventilation in commercial kitchens – Part 2 : kitchen ventilation hoods – Design and safety requirements (6) HACCP – Hazard Analysis Critical Control Point (7) Energy Efficiency in Buildings, Transforming the Market (WBCSD World Business Council for Sustainable Development)

Downloads

-

Halton FS MARVEL (MRV) nl

Data

Nederlands (nl) -

Halton FS MARVEL (MRV) fr

Data

Français (fr) -

Halton FS MARVEL (MRV) it

Data

Italiano (it) -

Halton FS MARVEL (MRV) da

Data

Dansk (da) -

Halton FS MARVEL (MRV) fi

Data

Suomi (fi) -

Halton FS MARVEL (MRV) de

Data

Deutsch (de) -

Halton FS MARVEL (MRV) sv

Data

Svenska (sv) -

Halton FS MARVEL (MRV) es

Data

Español (es) -

Halton FS MARVEL (MRV) pl

Data

Polski (pl) -

Halton FS MARVEL (MRV) ru

Data

Русский (ru) -

Halton FS MARVEL (MRV) en

Data

English (en) -

Halton FS MARVEL (MRV) zh

Data

简体中文 (zh) -

Halton FS EAC Certificate 02

Data

Русский (ru) -

Halton FS EAC Certificate 01

Data

Русский (ru) -

Halton RemoteMonitoring BR-016

Data

en_US -

Halton M.A.R.V.E.L.Brochure BR-002

Data

en_US

Request for Quotation

"*" indicates required fields