Product / WSO

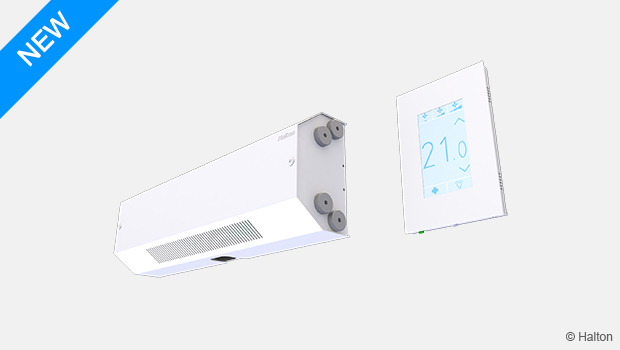

Halton Workplace WSO – System optimiser central unit

The Halton Workplace WSO ensures required ventilation airflow rates and reduces air handling unit (AHU) fan speed to improve energy efficiency.

It communicates with the building management system that is controlling air handling unit (AHU) and all zone dampers to optimise system performance in all circumstances.

- Part of Halton Workplace system

- Communication protocol: BACnet/IP

- Optimises AHU static pressure setpoint and zone damper openings

Overview

The Halton Workplace system is a solution offering room condition management, zone static pressure, and pressure optimisation of the air handling unit (AHU). The demand-based operation of the Workplace system ensures energy efficient operation, without compromising indoor air quality.

The Halton Workplace WSO ensures required ventilation airflow rates and reduces air handling unit (AHU) fan speed to improve energy efficiency. It communicates with the building management system that is controlling air handling unit (AHU) and all zone dampers to optimise system performance in all circumstances.

Halton Workplace WSO can be equipped with Halton Edge gateway to access the Halton Connect and Care IoT platform with cloud-based portal, to see system performance data for system maintenance and to connect with Workplace partner solutions.

The Halton Workplace system supports common BACnet communication protocol.

Application area

- Central control unit of Halton Workplace System

Key features

- Communication protocol: BACnet/IP

- Optimises AHU static pressure setpoint and zone damper openings

- Manages AHU minimum airflow limitation by communicating with room units

- Reduces air handling unit fan speed to improve energy efficiency

- Includes optional Halton Edge remote control

Operating principal

The Halton Workplace WSO manages air handling unit (AHU) fan operation based on the pressure and airflow demand of the system. It communicates with Halton Workplace Zone dampers (Halton Max MDC). If all zone dampers are regulating, airflow although the least demanding zone damper should be fully open with low pressure drop. The Halton Workplace WSO manages the air handling unit (AHU) fan pressure accordingly to keep the pressure level at lowest possible value to reach the desired zone airflow. This reduces the energy consumption of AHU fans and keeps the system at optimal operation conditions.

Same time the Halton Workplace WSO manages AHU minimum airflow limitation by communicating with room units. If AHU airflow is below minimum airflow limit, for instance in situation when most of the room units are operating with minimum airflow rate, The Halton Workplace WSO increases airflow rate in room level in order to maintain AHU airflow at minimum airflow limit.

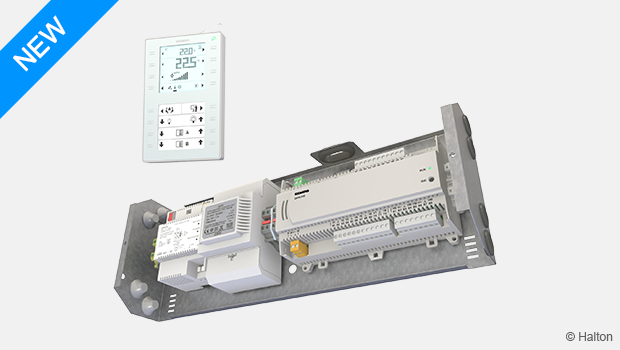

The Halton Workplace WSO consists of two hierarchic levels of operation: the manager module and zone dampers. The functions of each are outlined below.

Halton Workplace WSO – System optimiser controller

- Collects information from zone dampers

- Calculates AHU static pressure setpoint

- Operates with network or 0-10 VDC to BMS

- Manages AHU minimum airflow limitation by communicating with room units

Zone dampers

- Communication with the Halton Workplace System Optimiser

- Damper blade position and zone airflow

- Pressure and airflow control of zone

Key technical data

| Feature | Value |

| Communication interface | BACnet/IP |

| Protection class | Controller: IP 20 |

| Transformer |

|

| Product options |

|

| Maintenance | Maintenance free |

Structure and components

| No. | Part | Details |

| 1 | Halton Edge gateway | Remote control unit |

| 2 | Halton Workplace WSO | Siemens DXR2.E18 controller |

| 3 | Transformer | 230/24V AC 20VA transformer |

| 4 | Power socket | Power supply for Halton Edge gateway |

Dimensions and weight

Weight:

5 kg

Specification

The Halton Workplace WSO monitors the performance of the ventilation system. Minimises energy consumption by keeping the lowest possible pressure level in the ductwork. Includes optionally Halton Edge gateway remote control to access the Halton Connect and Care cloud-based portal.

Construction

- The Halton Workplace WSO controller unit is delivered installed in installation cabinet.

- Transformer and controller unit is installed in cabinet with space reservation for Halton Edge gateway

Material

- Installation cabinet: polycarbonate

Electrical data

- Communication protocol: BACnet/IP

- Power supply voltage 230 V AC

Communication cable (BACnet/IP)

- Standard Ethernet cable:

- Min. category 5

- Shielded or unshielded

- Length between router/switch and room automation station: max. 100 m

- Length between room automation stations: max. 100 m

- Number of devices under a line topology: max. 20

Parameter settings

- Controller settings are adjustable on site with BACnet/IP connection or web browser

Installation

Installation options

The Halton Workplace WSO manager is delivered with own installation cabinet with transformer with direct din-rail mounting or wall-mounting.

Space requirements

Space needs to be reserved for installation cabinet so that the Halton Workplace WSO is accessible. Installation cabinet has space reservation for Halton Edge gateway.

Wiring

Controller connections

| Pin | Description | Terminal | Module | Channel |

| 1, 2 Ethernet | 2x RJ45 interface for 2-port ethernet switch |  |

– | – |

| 11, 12 KNX | KNX connection | +, – | – | – |

| 31…41 inputs | Digital input | D1, D2 | 1 | 1, 2 |

| Universal input | X1…X4 | 1 | 5…8 | |

| System neutral | Ʇ | – | – | |

| Field supply AC 24 V for active sensors | V~ | – | – | |

| Field supply DC 24 V for active sensors | V+ | – | – | |

| USB | USB interface | – | – | |

| 51…52 power 24 V AC | Power supply SELV / PELV AC 24 V | V~ | – | – |

| System neutral | Ʇ | – | – | |

| 61…72 Triac outputs | Switching output AC 24V | Y1…Y8 | 11 | 1…8 |

| System neutral | Ʇ | – | – | |

| 81…88 analog outputs | Positioning output DC 0…10 V | Y10…Y40 | 21 | 1…4 |

| System neutral | Ʇ | – | – | |

| Field supply AC 24 V | V~ | – | – | |

| Service | Service button | SVC | – | – |

| Display | Operation LED | RUN | – | – |

Wiring schematics

Fig.1. Wiring diagram for Workplace System Optimiser (WSO) with analogue connections from air handling unit (AHU)

Fig.1. Wiring diagram for Workplace System Optimiser (WSO) with analogue connections from air handling unit (AHU)

Fig.2. Wiring diagram for Workplace System Optimiser (WSO) with BACnet/IP connection for air handling unit (AHU)

Fig.2. Wiring diagram for Workplace System Optimiser (WSO) with BACnet/IP connection for air handling unit (AHU)

Commissioning

The Halton Tune commissioning support and start-up services guarantee proper functionality of the ventilation system before the occupants move in. By ensuring that all installations of components have been made correctly, and all parameters have been set according to the design, optimal thermal conditions and energy savings are achieved. Halton helps you provide a fully functional, comfortable, and safe indoor climate for the building users.

Halton supplies its customers with Halton Tune commissioning support and start-up services according to the following table.

| Service concept | Contents of service provided by Halton | Customer’s responsibilities |

| Services performed prior to delivery |

|

|

| On-site commissioning services |

|

|

Order code

WSO/C, ZT

C =Control unit and remote connection

O System optimiser controller

E Halton Edge gateway

B System optimiser + Halton Edge gateway

Other options and accessories

ZT = Tailored product

Y Yes (ETO)

Order code example

WSO/O, ZT=N

Downloads

"*" indicates required fields