Product / MUA-DG

Halton’s MUA-DG Direct Fired Make-Up Air Units are engineered to deliver a consistent supply of tempered outdoor air to commercial kitchens and large facilities. Whether you’re managing a high-volume restaurant, a food processing center, or an institutional kitchen, the MUA-DG system provides an energy-efficient solution to maintain indoor air quality, pressurization, and thermal comfort. Direct gas is now an excellent option for pairing with demand-controlled kitchen ventilation, offering air turndown capabilities that align seamlessly with our M.A.R.V.E.L. system.

With Halton’s signature quality, the MUA-DG is built for durability and performance, even in the most demanding ventilation environments.

Enhance Your Ventilation Strategy with Halton

Make-up air systems are designed to support the performance of your kitchen and overall operating efficiency. Halton’s MUA-DG Units provide fresh air accurately where and when it is required.

Module Options

DX Cooling

For applications requiring cooling, Halton’s MUA-DG units can be equipped with DX (Direct Expansion) cooling to provide precise temperature control and enhanced comfort. This integrated option uses a refrigerant-based system to cool incoming air efficiently, making it ideal for hot climates or facilities with high internal heat loads. DX cooling delivers reliable performance with a compact footprint and reduced energy consumption.

Evaporative Cooling

Halton MUA-DG units can be configured with evaporative cooling for an energy-efficient solution in dry or arid climates. This system cools incoming air by passing it over water-saturated media, lowering temperatures without using compressors or refrigerants. It is an option that reduces energy consumption and operational costs while maintaining effective ventilation and occupant comfort.

Hydronic Heating & Cooling

Halton MUA-DG units can also be configured with Hydronic Heating & Cooling for facilities that utilize hot water or chilled water systems. This option provides thermal control through water-based heat exchange, offering a quieter, low-maintenance alternative to direct-fired or refrigerant-based systems. The hot and chilled water modules use existing building water systems such as a boiler, chiller, or energy recovery device to transfer heat to or from the Make-up air stream. Hydronic heating and cooling can be used as a primary heating or cooling source or to supplement gas heat, DX cooling, or heat pump systems.

Heat Recovery

To maximize energy efficiency, Halton’s MUA-DG units can be configured with heat recovery options that capture and reuse energy from exhaust air streams. By transferring heat to the incoming make-up air, these systems reduce the load on heating and cooling components, lowering energy consumption and operational costs. Heat recovery is an ideal solution for facilities focused on sustainability, offering improved indoor air quality without sacrificing efficiency

Why Choose Halton MUA-DG?

Reliable Ventilation Performance

Provides a steady supply of outdoor air to replace exhausted kitchen air, helping maintain positive building pressure and a comfortable environment.

Integrated with Demand-Controlled Ventilation

Seamlessly integrates with Halton’s M.A.R.V.E.L. DCKV system and Halton SafeGuard for intelligent modulation based on real-time kitchen activity, optimizing airflow and energy savings.

Customizable Airflow & Capacity

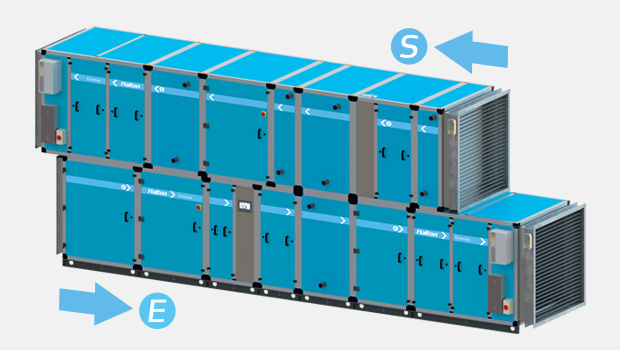

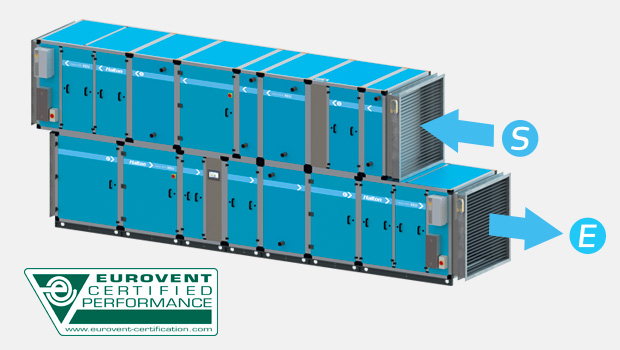

Available in multiple sizes and configurations to meet your facility’s unique airflow requirements — whether rooftop or indoor-mounted.

Features

- DX Cooling Capacities from 1,800 CFM to 12,600 CFM – 60335-2-40 Certified for R454b

- Remote Condensers up to 20 tons

- Direct Drive, Plenum Fan

- Rolled Steel, ODP Blower motor

- EC Fan

- Motorized intake damper

- Unit Mounted Discharge Temp. Controls

- Remote Start/Stop

- Constant volume

- Unit mounted Non-Fused Disconnect

- Neoprene Fan Isolators

- End or Bottom discharge

- 1” Insulation, double wall

- Heavy Hinged Doors

- G90 Galvanized, unpainted

Available Options

- TEFC Blower Motor (Rolled Steel or Cast Iron)

- Intake Hood w/ 2” Alum. Mesh Filters & Bird Screen

- MERV 8 Dust Filters

- Gravity Intake Damper

- Remote DAT (Discharge Air Temp.) or

- Freeze Stat

- Variable Volume (Halton provides VFD)

- Seismic Blower Isolators

- Roof Curb (Optional Insulation & Nailer)

- Uninsulated

- Gas Pressure Gauges

- High and Low Gas Pressure Switches

- Gas Regulator (Field Installed)

- Special Coating

- Automated Profile Plates

- 30% Air Turndown

- Pair with Halton’s SafeGuard System for remote monitoring

Frequently Asked Questions

Where are direct fired MUA units commonly used?

Direct fired units are best suited for restaurants, foodservice kitchens, warehouses, and manufacturing facilities where code permits limited exposure to combustion byproducts and where efficiency, cost and heating speed are priorities.

Does it integrate with demand-controlled ventilation?

Yes. The MUA-DG integrates seamlessly with Halton’s M.A.R.V.E.L. system (DCKV), which adjusts airflow based on real-time cooking demand—significantly reducing energy usage and improving air balance. Halton Direct Gas MUA is a great choice with DCKV as its air turndown can match that of the DCKV system.

Is the MUA-DG suitable for all climates?

Yes. Halton can configure the unit with appropriate heating and cooling components—including high-efficiency burners and optional cooling modules—to handle hot, cold, or variable climates.

How is the system maintained?

Halton designs its systems for ease of maintenance, with service access panels, diagnostics-ready controls, and optional remote monitoring. Routine maintenance includes checking burner operation, filters, and control sequences. Controls overrides are present on the HMI for commissioning and servicing.

What is the typical application for Direct Gas Heating (MUA-DG) units?

Direct gas heating is typically specified for make-up air in kitchens. It is not commonly used for space conditioning, although there have been instances where it has been used for space heating, such as in small, ventilated areas like shower areas.

What are the efficiency levels of Direct Gas units compared to Indirect Gas units?

Direct gas units are 100% efficient thermodynamically but are 92% efficient from an HVAC heating standpoint due to moisture generated by combustion. Indirect gas units are typically between 80-90% efficient.

What are the safety considerations for Direct Gas units?

Direct gas units have combustion byproducts in the air stream, including CO, CO2, and NOx, but these are in very tiny quantities and regulated by safety standards. The burners are optimized to produce less than 5 ppm CO and less than 0.5 ppm NOx, which is sometimes less than ambient conditions in kitchens. Due to air changes in commercial kitchens the biproducts are typically unmeasurable relative to background levels.

What are the maximum temperature rise and discharge air temperature for MUA-DG units?

The maximum temperature rise allowed for MUA-DG units is 100°F, and the maximum discharge air temperature is 140°F.

What are the available sizes for Direct Gas MUA units?

Direct gas MUA units are sold in 6 sizes when sold without cooling (heat only) ranging from 0-16000 CFM, and in 5 sizes when sold with cooling ranging from 0-13000 CFM

What are the key components of MUA-DG units?

Key components include the burner and gas train, which are provided and listed by a company that leak checks and test fires the burner/gas train. The burners have an input rate capacity of 750,000 BTU/HR per foot of length, although this capacity is not typically fully utilized in these units

What are the design and layout considerations for Direct Gas units?

Direct gas units with evaporative cooling have the cooling section before the burner, while units with DX cooling have the coil after the burner. The fan cabinet is always the last section on the unit, and units can be configured for both horizontal and vertical discharge.

What are the control options for MUA-DG units?

Control options include unit-mounted DAT (Discharge Air Temperature) controllers, remote DAT, and remote DAT temperature controls. The units can have either direct spark or piloted gas valve trains

What are the operational procedures for MUA-DG units?

When the unit is powered on, the blower will be enabled to provide airflow unless set up for remote start/stop. If there is a call for heat, the burner will ignite, provided airflow is within the acceptable range. If the burner fails to ignite, the unit will reset call for heat after a few minutes. After ignition the unit will maintain the required discharge air temperature (DAT).

Learn more about make-up air

How not to ruin a good thing, Make-up Air 101

When replacement air is brought into a kitchen, it needs to be distributed through louvers, vents, diffusers, plenums, etc. It’s not good practice and would be another article, to just “dump” the air in the space through a duct with nothing on the end.

Downloads

Contact Us

For inquiries, request a quotation or ask our specialists. We are here for you.

Our team looks forward to hearing from you. Please fill in the form. We’ll be in touch with you shortly.

"*" indicates required fields