Product / MUA-IF

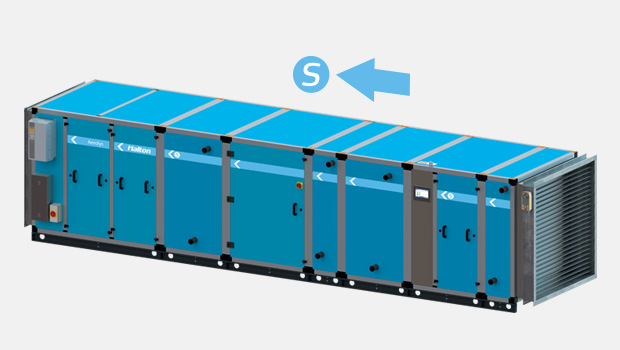

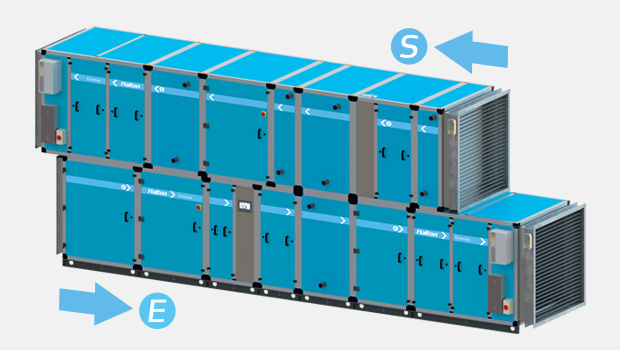

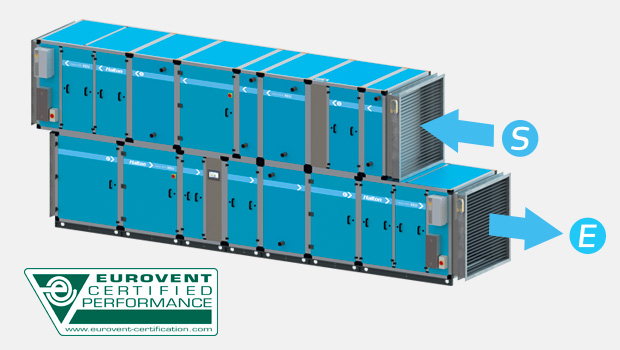

Halton’s Indirect Fired Make-Up Air Units (MUA-IF) provide reliable tempered outdoor air to commercial kitchens, industrial spaces, and institutional facilities where combustion-free airstreams are required. These systems utilize a sealed heat exchanger to warm the air without direct contact with combustion gases, making them ideal for applications that prioritize cleanliness and precise control.

Built for performance and long-term efficiency, Halton’s indirect-fired MUA systems integrate seamlessly with your ventilation infrastructure and energy-saving strategies.

Halton units provide a high level of air quality inside the kitchen and work “hand-in-hand” with PolluStop pollution control units and Halton’s M.A.R.V.E.L. Demand Controlled-Kitchen Ventilation (DCKV).

Enhance Your Air Quality Strategy with Halton

Every make-up air solution should meet the highest standards for safety, performance, and indoor air quality. Halton’s Indirect Fired MUA units deliver clean, conditioned air with precision—supporting your facility’s comfort, compliance, and operational goals.

Optional Modules

DX Cooling

Integrated DX (Direct Expansion) cooling allows for precise air temperature control using a refrigerant-based coil system. This compact solution is perfect for facilities that need efficient cooling with minimal energy use and footprint.

Evaporative Cooling

Halton offers evaporative cooling as a low-energy alternative, particularly effective in dry climates. It cools air by drawing it through water-saturated media, delivering comfort without mechanical refrigeration or high energy demand.

Hydronic Heating & Cooling

Hydronic coils are available for facilities utilizing hot water or chilled water systems, offering quiet operation and compatibility with centralized plant infrastructure. This option ensures consistent performance with low maintenance.

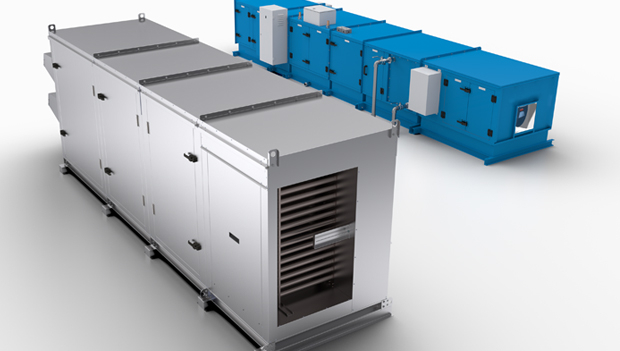

Heat Recovery

Improve energy efficiency with optional heat recovery systems, which reclaim heat from exhaust air to pre-condition incoming fresh air. This reduces load on primary heating systems, lowers utility costs, and supports sustainability goals.

Why Choose Halton’s Indirect Fired Make-Up Air Units?

Reliable Indoor Air Quality

Delivers clean, tempered make-up air to maintain building pressurization, kitchen comfort, and code compliance in sensitive facilities.

Versatile Design Options

Available in a variety of capacities and configurations with options for rooftop or indoor installation, advanced filtration, and integrated cooling.

Smart Energy Control with Halton M.A.R.V.E.L. DCKV

Can be paired with Halton’s M.A.R.V.E.L. demand-controlled kitchen ventilation system for dynamic airflow modulation based on real-time cooking activity—optimizing energy use and operational efficiency.

Promotes Sustainability Objectives

When combined with heat recovery, Halton’s indirect units reduce overall energy consumption and contribute to green building certifications.

Features

- DX Cooling Capacities 1800CFM to 13000 CFM, 60335-2-40 Certified for R454b

- Remote Condensers up to 25 ton

- EC Fan

- Rolled Steel, ODP Blower motor

- Motorized intake damper

- Unit Mounted Halton Discharge Air Temp. Controls

- Unit Mounted Call for Heat

- Remote Start/Stop

- Constant volume

- Unit mounted

- Non-Fused Disconnect

- Neoprene Fan Isolators

- End or Bottom discharge

- 1” Insulation, double wall

- G90 Galvanized, unpainted

- Heavy Duty Hinged Doors (add to DG too)

- 10:1 Gas Turn Down

Options Available

- Direct Drive, Plenum Fan

- TEFC Blower Motor (Rolled Steel or Cast Iron)

- Intake Hood w/ 2” Alum. Mesh Filters & Bird Screen

- MERV 8 Dust Filters

- Remote DAT (Discharge Air Temp.)

- Freeze Stat

- Variable Volume (Halton provides VFD)

- Heat Recovery (HRU) Module

- Up to 30:1 Gas Turn Down

- Air Turn Down up to 30:1

- Seismic Blower Isolators

- Roof Curb (Optional Insulation & Nailer)

- Gas Regulator (Field Installed)

- Special Coil Coating

- Pair with Halton’s SafeGuard System for remote monitoring

Frequently Asked Questions

What is an indirect fired make-up air unit?

An indirect fired make-up air unit heats outdoor air using a sealed heat exchanger, keeping combustion gases completely separate from the supply air. This ensures clean, tempered air delivery—ideal for environments with strict air quality requirements.

Where are indirect fired units typically used?

These units are ideal for healthcare facilities, food processing plants, laboratories, schools, and any application where tempered air is required and air purity is a priority.

Do Halton’s units support demand-controlled ventilation?

Absolutely. Halton’s indirect fired units are fully compatible with M.A.R.V.E.L. demand-controlled ventilation, allowing real-time airflow modulation based on kitchen activity. This enhances efficiency and reduces energy waste.

Can Halton’s indirect fired units be paired with cooling systems?

Yes. Halton offers DX cooling, evaporative cooling, and hydronic cooling options, allowing you to customize your unit based on climate, facility needs, and energy goals.

What is the maximum discharge temperature for Halton’s indirect fired units?

The maximum discharge temperature for MUA-IF units is 140°F, but it is typically limited to 90°F .

What is the efficiency of indirect fired MUA-IF units?

Indirect-fired MUA-IF units are approximately 80% efficient.

What are the gas supply pressure requirements for MUA-IF units?

The minimum gas supply pressure is 7 inches water column (w.c.), and the maximum is 14 inches w.c.

What is the turndown ratio for modulating and staged burners in MUA-IF units?

Modulating burners have a turndown ratio of 10:1, while staged burners have a turndown ratio of 2:1. The total turndown ratio on the largest unit can be up to 30:1, depending on the burner configuration

What are the clearances required for Halton’s indirect fired units?

Clearances to combustibles are 0 inches on the top and bottom, and 1 inch on the inlet and discharge ends. Service clearances are 42 inches on the controls side and 18 inches on the burner side

What materials are used for the burner/heat exchanger tubes in MUA-IF units?

The burner/heat exchanger tubes are made of 400 series stainless steel

What are the control requirements for modulating and staged burners in Halton’s indirect fired units?

Modulating burners require a call for heat and a 0-10V signal (at least 2.5V) to start the ignition cycle. Staged burners require R/W signals and can be dual or split manifold.

What is the maximum external static pressure for Halton’s indirect fired units?

The maximum external static pressure for MUA-IF units is 1.5 inches w.c. .

What safety features are included in MUA-IF units?

Each burner has a safety valve (On/Off), and the burner control board is connected to safety sensors. Burners will not fire if the air temperature is above ~200°F, the pressure switch is closed, or the gas is not ignited.

What is the minimum and maximum temperature rise allowed for MUA-IF units?

The maximum temperature rise allowed is 100°F, and the minimum temperature rise is 20°F.

Downloads

Contact Us

For inquiries, request a quotation or ask our specialists. We are here for you.

Our team looks forward to hearing from you. Please fill in the form. We’ll be in touch with you shortly.

"*" indicates required fields