Product / ELC

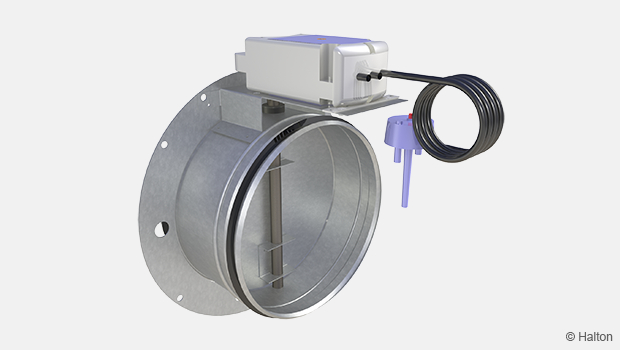

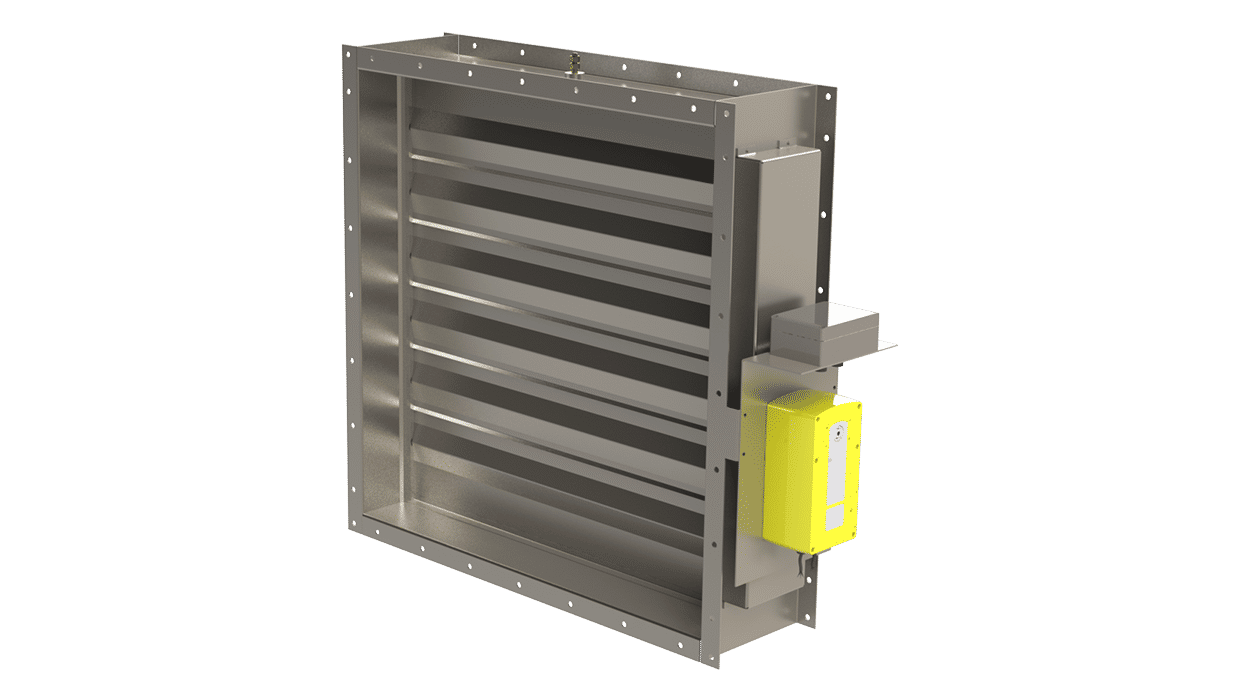

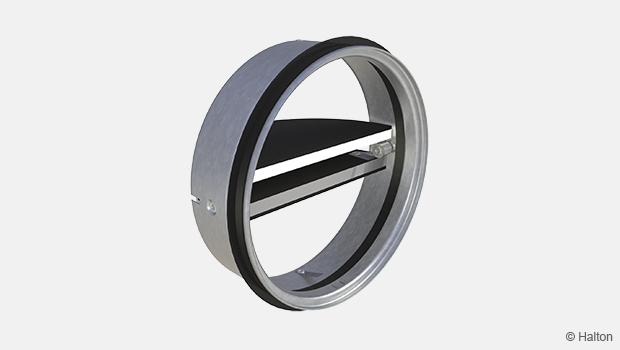

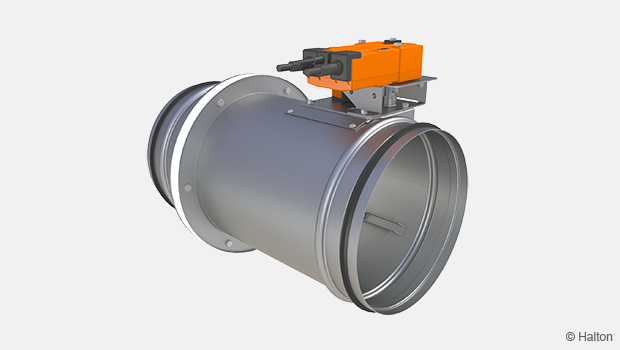

Halton Exe ELC – Fire damper (E 120 S)

This non-insulated CE marked fire damper is one of the shortest in the market and so utilising minimal space.

Fire resistance class is provided up to E 120 S requirements in all installation options.

- Can be installed up to 1.0 m away from the separate element (E 120 S)

- Sizes from Ø100 mm up to 500 mm are available

- Material options galvanised or stainless steel (EN 1.4404/AISI 316L) available

Overview

This non-insulated fire damper is one of the shortest in the market and so utilising minimal space. The light construction makes installation easy. Installation option up to 1.0 meter away from the structure has been certified. Fire resistence class is provided up to E 120 S requirements in all installation options.

Features

- Supplied with electrical spring return actuator (24 V or 230 V), 0 -10 V modulating actuator (24 V) or mechanical spring release (failsafe)

- Sizes from Ø100 mm up to Ø500 mm are available

- Maximum air speed through fire damper in open position is 15 m/s

- Suitable for use in ducts with a maximum pressure difference of 3300 Pa

- Material options galvanised or stainless steel (EN 1.4404/AISI 316L) available

- No spare parts or additional installation frames needed, regardless of installation method

Installation options

- Vertical (wall) and horizontal (ceiling/floor) installation

- Spindle of the blade and the operating models (electric actuator or mechanical spring release) can be installed in any position (360 °) in wall installation

- Can be installed up to 1.0 m away from the separate element (E 120 S)

- Installation in concrete, masonry or lightweight structure (wall or ceiling/floor) which have fire resistance classes of EI 120, EI 90 or EI 60

Standards

This product complies with the following standards:

- CE certified according to product standard EN 15650

- Fire classification according to EN 13501-3+A1 standard

E 120 (ve ho i↔o) S, E 90 (ve ho i↔o) S, E 60 (ve ho i↔o) S - Fire testing according to EN 1366-2

- CE certificate of constancy of performance, No: 2434-CPR-0035

- Declaration of Performance, No: 10029-ELC-2019/04/04

- Leakage through closed damper blade fulfils class 4 according to EN 1751

- Damper casing tightness class C according to EN 1751

- Manufactured in accordance with ISO 9001 quality system

Dimensions and weight

With electric actuator

| NS | ØD | Ø D1 | L | L1 | L2 |

| 100 | 99 | 197 | 163 | 120 | 43 |

| 125 | 124 | 222 | 163 | 120 | 43 |

| 150 | 149 | 247 | 163 | 120 | 43 |

| 160 | 159 | 257 | 163 | 120 | 43 |

| 200 | 199 | 297 | 163 | 120 | 43 |

| 250 | 249 | 347 | 163 | 120 | 43 |

| 315 | 314 | 412 | 163 | 120 | 43 |

| 350 | 349 | 447 | 163 | 120 | 43 |

| 400 | 399 | 530 | 163 | 120 | 43 |

| 500 | 499 | 630 | 245 | 143 | 102 |

With mechanical spring release

| NS | ØD | Ø D1 | L | L1 | L2 |

| 100 | 99 | 197 | 197 | 153 | 43 |

| 125 | 124 | 222 | 197 | 153 | 43 |

| 150 | 149 | 247 | 197 | 153 | 43 |

| 160 | 159 | 257 | 197 | 153 | 43 |

| 200 | 199 | 297 | 197 | 153 | 43 |

| 250 | 249 | 347 | 197 | 153 | 43 |

| 315 | 314 | 412 | 197 | 153 | 43 |

| 350 | 349 | 447 | 197 | 153 | 43 |

| 400 | 399 | 530 | 197 | 153 | 43 |

| 500 | 499 | 630 | 245 | 143 | 102 |

Weight (kg)

| NS | With electric actuator |

With mechanical spring release |

| 100 | 2.2 | 1.3 |

| 125 | 2.3 | 1.4 |

| 150 | 2.4 | 1.6 |

| 160 | 2.5 | 1.7 |

| 200 | 2.9 | 2.0 |

| 250 | 3.4 | 2.5 |

| 315 | 4.0 | 3.2 |

| 350 | 4.9 | 3.9 |

| 400 | 5.6 | 4.7 |

| 500 | 6.0 | 5.1 |

Structure and material

| Nr | Part | Material | Note |

| 1 | Casing | Galvanised steel | Stainless steel as option (EN 1.4404/AISI 316L) |

| 2 | Blade | Galvanised steel | Stainless steel as option (EN 1.4404/AISI 316L) |

| 3 | Mounting flange | Galvanised steel | Stainless steel as option (EN 1.4404/AISI 316L) |

| 4 | Shaft | Stainless steel | – |

| 5 | Blade gasket | e-cloth | – |

| 6 | Duct gaskets | 1C-polyurethane hybrid | – |

Operating models

Electric actuator

In the electric actuator system (24 V and 230 V) when a signal from building automation reaches the actuator or the fuse reacts to a rise in temperature (72 °C) power supply is switched off and the spring closes the blade of the damper. When the power supply is turned back on (e.g. during routine testing), the actuator opens the blade. In case of a power failure, the mechanical spring of the actuator ensures the failsafe function by closing the blade.

The actuators are equipped with built-in limit switches for both open and closed position and have a visual position indicator.

The fuse can be replaced from outside the device.

AC/DC 24 V (N1)

The Halton Exe Light Circular fire damper with the 24 V electric actuator option must be connected to buildings fire damper management control system, e.g. We recommend our Modbus based network solution Halton Safe Management 2.0 (SM2) control and testing system. This system enables the use of smoke detectors in ductwork or room spaces.

Operationally, when the Halton Safe Management 2.0 (SM2) receives a signal from the fire alarm or smoke detector the power supply is turned off and the spring return actuator drives the damper blade to closed position. When the power supply is turned back on (e.g. during routine testing) the actuator drives the damper blade to open position.

The fire damper can also be connected to other commonly used building automation systems.

AC 230 V (N2)

The Halton Exe Light Circular fire damper with the 230 V electric actuator option must be connected to buildings fire damper management control system.

AC 24 V / DC 24…48 V, modulating (N3)

The Halton Exe Light Circular fire damper with modulating actuator has two features: It can be used for VAV purposes in air ventilation systems and at same time as a fire damper.

The fire damper must be connected to buildings fire damper management control system.

| Order code |

Operating model |

Damper sizes (ØD, mm) |

Operating voltage | Limit switch |

| N1 | GNA 126.1E-T12, 7 Nm |

100 – 500 | AC/DC 24 V | ✔ |

| N2 | GNA 326.1E-T12, 7 Nm |

100 – 500 | AC 230 V | ✔ |

| N3 | GNA 166.1E/T12, 7 Nm (modulating) |

100 – 500 | AC/DC 24 V | ✔ |

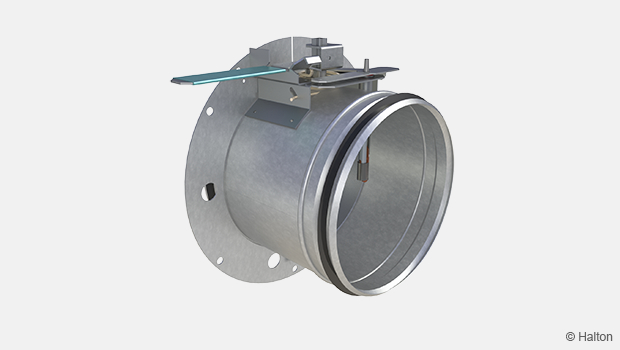

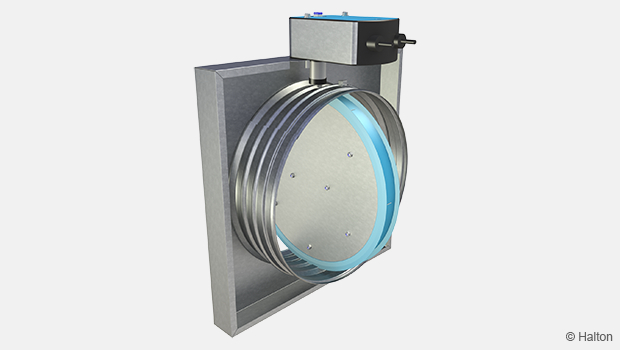

Mechanical spring release (failsafe)

In Halton Exe Light Circular fire damper with mechanical spring release (Fig.1.), the fuse reacts to the rise of temperature (70 ºC) and the mechanical spring closes the blade of the damper. It needs to be opened manually.

This operating model has a visual position indicator and fuses can be replaced from outside the device.

Fig.1. With mechanical spring release

The limit switch (accessory) indicates the position of the damper blade. When it is open (safe position), the limit switch indicates this position. If the damper blade is closed (failsafe), the limit switch sends an impulse to the monitoring system. This system triggers an alarm and/or stops/starts fans, depending on the designed system. The limit switch has no influence on the thermal fuse or release mechanism.

The maximum operating voltage and current is 400 V, 10 A.

| Limit switch | LS1 | Closed position indication, enclosure class IP 65 (Fig.2.) |

| Limit switch | LS2 | Open/closed position indication, enclosure class IP 65 (Fig.3.) |

Fig.2. With one limit switch Fig.3. With two limit switches

Function

The Halton Exe Light Circular fire damper is CE certified for vertical (ve) and horizontal (ho) installation in concrete, masonry or lightweight structures. It fulfils the fire resistance class up E 120 (ve ho i↔o) S requirements.

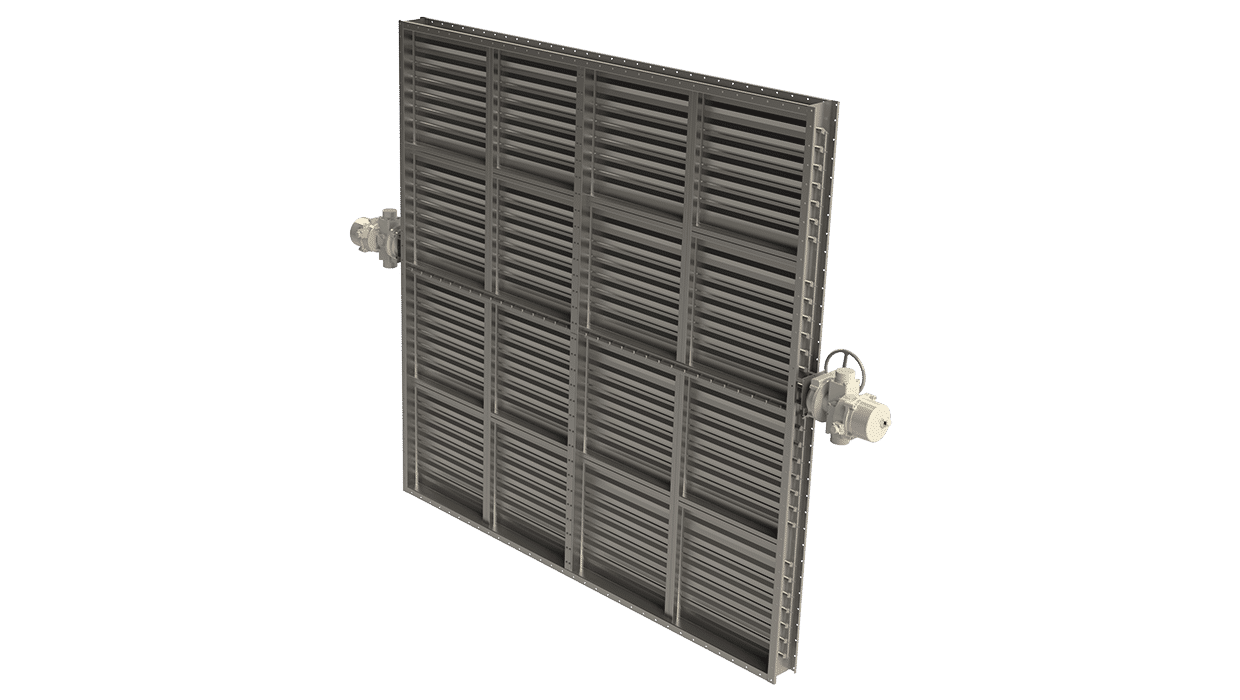

General

Fire dampers are shutters in ventilation duct systems and prevent spreading of the fire and smoke from one fire department to the other. They are equipped with either an electric operating model (actuator) or mechanical spring release (failsafe). Under both options, a fuse reacts to a rise in temperature, causing a spring-return damper blade to close position.

A fire damper with electrical actuator must be connected to a common fire alarm or building automation system.

In the electric actuator (24 V or 230 V) system, when a signal from building automation reaches the actuator or the fuse reacts to a rise in temperature (72 °C), the power supply is switched off, the spring closes the damper blade and seals the duct fire and smoke tightly. When the power supply is turned back on (e.g. during routine testing), the actuator opens the damper blade. The actuator is equipped with built-in limit switches for both open and closed position.

Alternatively, the fire damper can be delivered with a mechanical spring release (fail safe) with a fuse that reacts to the rise of temperature (70 ºC) and the mechanical spring closes the damper. It needs to be opened manually.

Fire damper management system

It is recommended that the fire damper with an electrical actuator is connected to an automatic fire damper management system, e.g. Halton Safe Management 2.0 (SM2) with operating voltage AC 24 V. Testing for fire dampers can be done automatically in Halton Safe Management 2.0 (SM2) .

Only fire damper with 24 V electric actuator can be connected to the Halton Safe Management 2.0 (SM2) control and testing system. It enables the use of smoke detectors in ductwork or in the rooms.

Operationally, when the Halton Safe Management 2.0 (SM2) receives a signal from the fire alarm or smoke detector the power supply is turned off and the spring return actuator drives the damper blade to the closed position. When the power supply is reinstated (e.g. during routine testing) the actuator drives the damper blade to the open position.

The Halton Exe Light Circular fire damper can also be connected to common building automation systems.

Installation

Please see/download Installation Guide for this fire damper from section Downloads.

Servicing

No regular maintenance is required for the product.

To ensure proper operation of fire dampers, inspection must be carried out regularly according to local building codes. The minimum recommended inspection period is every 6 months. Documentation of testing needs has to be saved for future needs.

A fire damper with electrical actuator must be connected to a common fire alarm or building automation system.

It is recommended that the fire damper with an electrical actuator is connected to an automatic fire damper management system, e.g. Halton Safe Management 2.0 (SM2) with operating voltage AC 24 V. Testing for fire dampers can be done automatically in Halton Safe Management 2.0 (SM2).

The fuse of a fire damper equipped with an electric actuator must be replaced if the fuse has been released because of a rise of temperature in the duct. The fuse can be changed from outside the fire damper.

If the fuse of a fire damper with a mechanical spring release (failsafe) is worn out, it must be replaced.

The actuators (electrical and mechanical spring release) include position indicators, open and close

Upon failure during testing of the fire damper, maintenance service shall be ordered from an authorised Halton representative to ensure appropriate operation of the product.

Specification

The fire damper is CE certified and marked according to the standard EN15650 and fire tested according EN 1366-2 standard.

A fire damper of maximum fire resistence class E 120 (ve ho i↔o) S requirements.

The fire damper casing complies with the tightness requirements for EN 1751 class C. Internal leakage is class 4 according to EN 1751.

The fire damper can be installed both vertical and horizontal position in concrete, masonry or lightweight structures.

The spindle of the blade and the operating models (electric actuator or mechanical spring release) can be installed in any position (360°) in wall installation.

The fire damper can be installed away from the separate element up to 1.0 metre (E 120 S).

The casing and the blade of the fire damper are made of galvanised or stainless steel (EN 1.4404/AISI 316L).

In model with electric actuator, the fuse shall be activated at 72 °C.

In the mechanical spring release model, the fuse shall be activated at 70 °C.

The fire damper with electric operating model includes position indicators, open and close and is equipped with built-in limit switches for both open and closed position.

The fire damper with mechanical spring release includes one position indicator (open) or two position indicators (open and closed). It can be equipped with limit switch(es), open or open and closed.

Order code

ELC-D, MA-OP-FU-LS-ZT

D = Diameter of duct connection (mm)

100, 125, 150, 160, 200, 250, 315, 350, 400, 500

Other options and accessories

MA = Material

GS Galvanised steel

AS Stainless steel (EN 1.4404/AISI 316L)

OP = Operating model (actuators)

N1 GNA126.1E/T12 (72 °C) 24 V, 7 Nm

N2 GNA326.1E/T12 (72 °C) 230 V, 7 Nm

N3 GNA166.1E/T12 modulating (72 °C) 24 V, 7 Nm

MA Mechanical spring release, (70 °C, failsafe)

FU = Fuse release temperature

72 72 °C (electric actuator)

70 70 °C (mechanical spring release)

LS = Limit switch (for mechanical spring release)

NA Not assigned

LS1 Limit switch (closed)

LS2 Limit switches (open/closed)

ZT = Tailored product

N No

Y Yes (ETO)

Code example

ELC-100, MA=GS, OP=N1, FU=72, LS=NA, ZT=N

Downloads

-

Halton Exe ELC – Fire damper (E 120 S)

Data

en

-

Halton Exe ELC – Palopelti (E 120 S)

Data

fi

-

Halton Exe ELC – Brandgasspjäll (E 120 S)

Data

se

-

Installation guide – Halton Exe Light Circular (ELC)

Data

en_GB -

Asennusohje – Halton Exe Light Circular (ELC)

Data

FI -

Palo- ja savunhallintapeltien asennustodistus

Data

Suomi (fi) -

Installation Certificate for Fire Dampers (used in UK)

Data

English (en) -

Declaration of Performance (DoP) – ELC

Data

en_GB -

Construction Product Regulation (CPR) – ELC

Data

en_GB

"*" indicates required fields