Product / KGS-ETL

KGS – Kitchen grease duct safety control system (ETL)

For new or existing kitchens

ETL Listed – Halton’s KGS Duct Safety System monitors grease film deposits and provides an alarm to suggest cleaning is required. This system provides an objective method for determining cleaning intervals based on grease deposit levels consistent with NFPA-96 guidelines for cleaning or local regulations. The system also indicates if cleaning has been performed to a satisfactory level.

KGS is compatible with exhaust hoods new or existing kitchens.

Overview

- Monitors grease deposit levels in all ductwork.

- Mitigates hygiene and fire safety concerns.

- Allows operator to clean ductwork when required by grease deposit levels, not dictated by schedule.

- Compatible with new or existing exhaust ductwork.

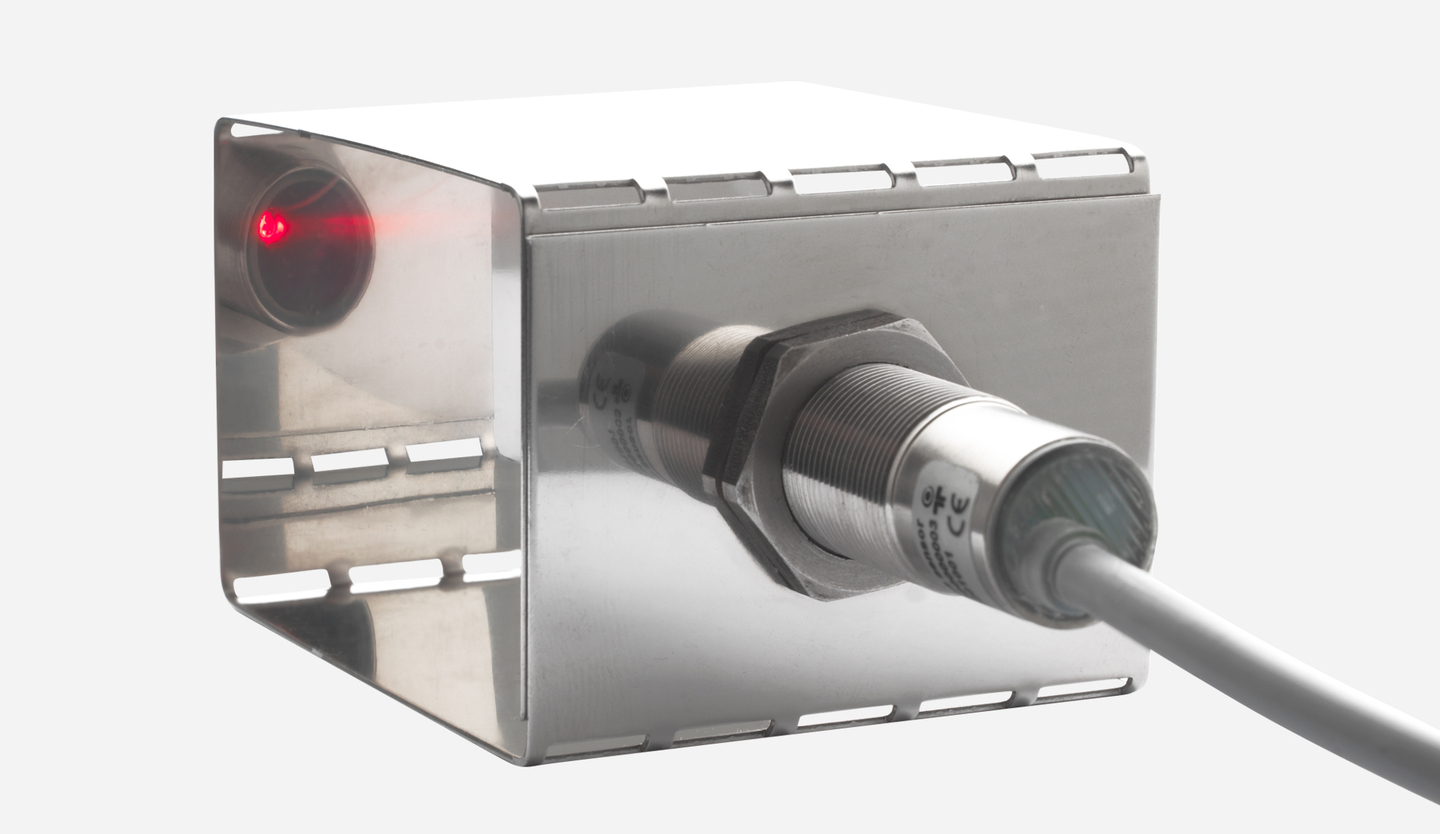

- Optical grease sensing device not affected by ambient light.

- Up to 10 grease sensors per system (extendable).

- Operates as a “stand alone” system.

- Grease sensor and reflector assemblies are UL1978 listed. Control panels are ETL listed.

Principles of operation

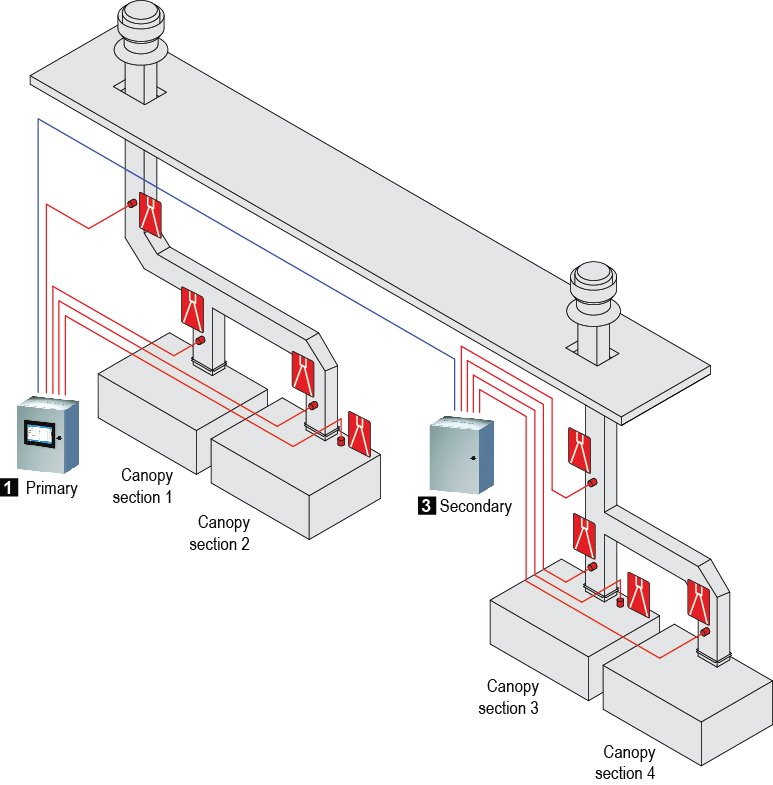

A – Primary control panel

B – Secondary control panel

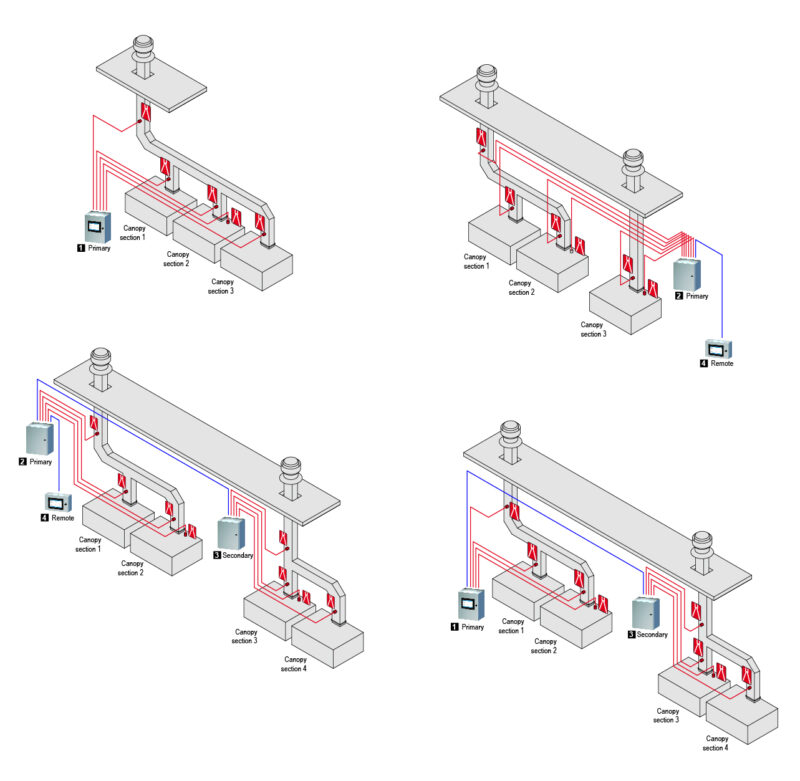

Design principles applied on hoods. Two areas managed by one Primary Control Panel combined with one Secondary Control Panel.

Construction

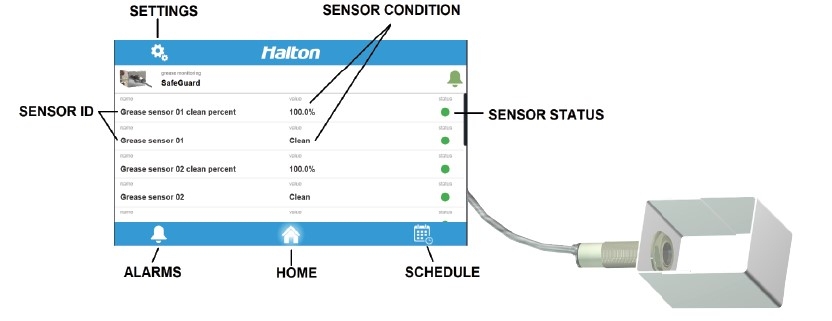

► KGS SCREEN DESCRIPTION

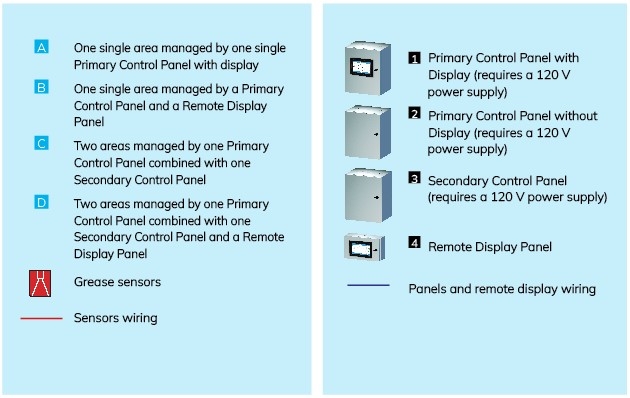

The controls of the KGS system are integrated inside a control panel. To simplify its installation, different models of control panels are available, completed by a remote display panel.

|

|

| Primary Control Panel with Display This control panel is stand-alone. It can handle up to 10 sensors. On it’s own, it is used ideally for kitchens with a single cooking area. To simplify the wiring in complex or large kitchens, it can be combined with a slave control panel. |

Secondary Control Panel The secondary control panel has to be systematically connected to a master control panel. It allows to split the sensors installed on the ductwork into several groups to simplify the wiring, depending on the kitchen configuration. |

|

|

| Primary Control Panel without Display This control panel has to be combined with a remote display. It can handle up to 10 sensors. On it’s own, it is used ideally for kitchens with a single cooking area. To simplify the wiring in complex or big kitchens, it can be combined with a slave control panel. |

Remote Display Panel It allows to separate the display from the controls. A master control panel – and possible slave control panel(s) – can then be installed inside the bulkhead, depending on the kitchen configuration. It can also handle up to 10 sensors. |

► KGS DESIGN PRINCIPLES APPLIED ON HOODS

|

|

Specification

The cooking area of the kitchen and the exhaust plenums of the canopies (ventilated ceiling) covering the heaviest cooking appliances shall be equipped with Halton’s KGS system. It shall be HACCP and UL certified.

Halton’s Duct Safety System (KGS) is a signaling device that monitors the grease deposit levels in all monitored ductwork. Once the level of grease exceeds the setpoint threshold an alarm is displayed on the system console alerting the operator that the ductwork has accumulated grease and should be cleaned.

The architecture of the system shall be based on the use of Primary and Secondary Control Panels and – if required – a remote display panel. If not required, one master control panel shall be equipped with the standard display as user interface of the system.

If the KGS system is combined with another system in the Halton High Performance Kitchen concept, KGS’s standard display shall be replaced by Halton’s Touch Screen.

Optionally, a signal can be sent to the Building Management System (BMS) via a “volt free” contact closure.

Type: KGS Manufacturer: Halton

Downloads

Contact Us

For inquiries, request a quotation or ask our specialists. We are here for you.

Our team looks forward to hearing from you. Please fill in the form. We’ll be in touch with you shortly.

"*" indicates required fields