Product / SFR

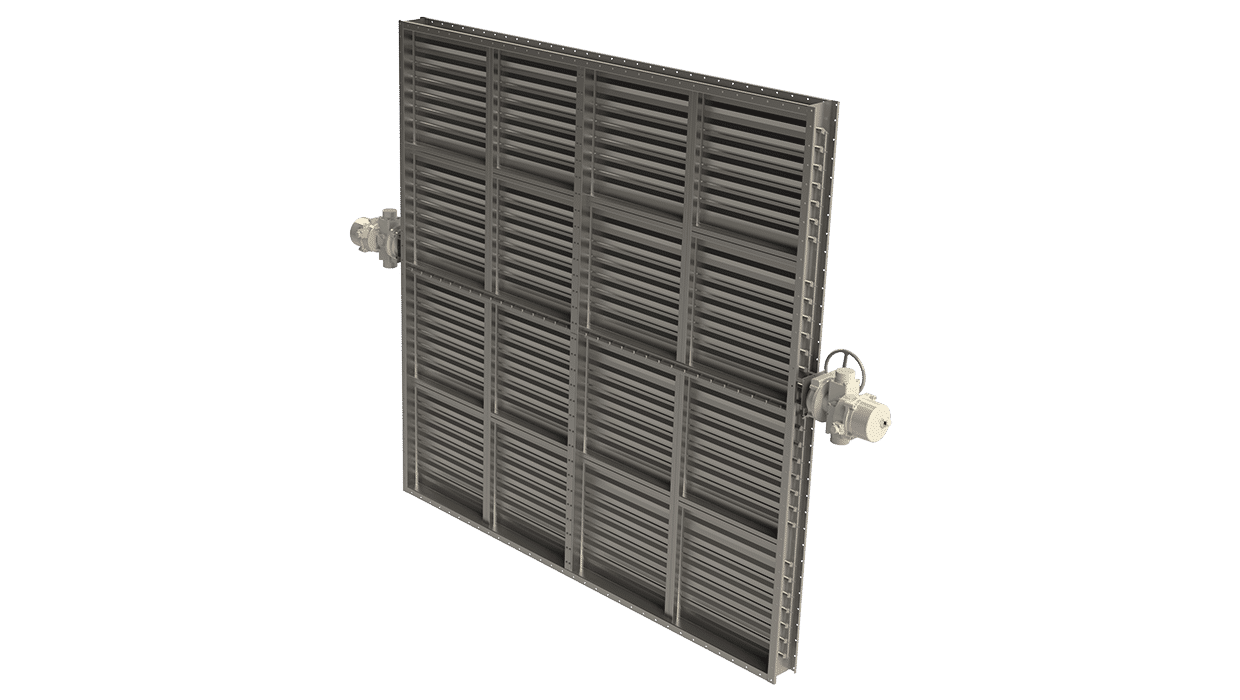

Halton Sec SFR – Smoke control damper (AAsingle)

This CE marked single compartment smoke control damper for automatically activated system (AA) is one of the lightest in the market. Light construction makes installation easy.

It is suitable for installation to smoke extract ducts. Can also be installed direct to end of the smoke extract duct.

Fire resistance class for all installation options is provided up to E600 90 S requirements.

- Suitability for installation to the sides of the the horizontal smoke extract duct or directly to the end of the smoke extract duct

- Sizes from 200×200 mm up to 1600×1000 mm are available

Overview

This smoke control damper is one of the lightest in the market. Light construction makes installation easy. It is suitable for installation to smoke extract ducts. Fire resistence class for all installation options is provided up to E600 90 S requirements.

Features

- Supplied with electrical non-spring return actuator (24 V or 230 V)

- Installation to single zone fire compartment with automatically activated systems (AA)

- Sizes from 200×200 mm up to 1600×1000 mm are available

- Maximum air velocity through smoke control damper in open position is 15 m/s

- Suitability for use in smoke extraction ducts with a maximum of 1500 Pa under pressure

- Frame construction is galvanised steel

- No spare parts or additional installation frames needed, regardless of installation method

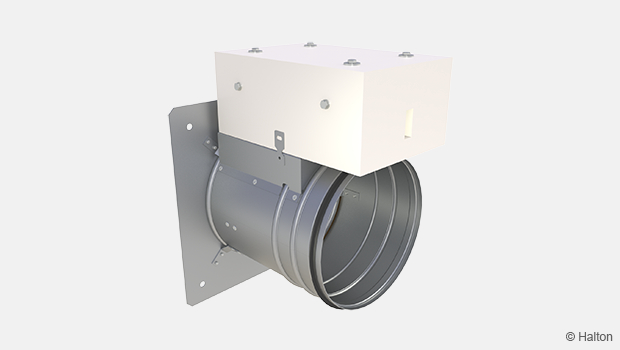

Installation options

- Suitability for installation to the sides of the the horizontal smoke extract duct or directly to the end of the smoke extract duct

Standards

This product complies with the following standards:

- CE certified according to product standard EN 12101-8

- Fire classification according to EN 13501-4 standard

E600 90 (ved-i↔o) S 1000C300 AAsingle - Fire testing according to EN 1366-10

- CE certificate of constancy of performance No: 1391-CPR-2018/0209

- Declaration of Performance No: 10036-SFR-2019/01/01

- Smoke control damper casing tightness class C according to EN 1751

- Leakage through closed damper blade fulfils class 2 according to EN 1751

Dimensions and weight

| W = Width [mm] | H = Height [mm] |

| 200, 250, 300, 350, 400, 450, 500, 550, 600, 700, 800, +100, … 1600 | 200, 250, 300, 350, 400, 450, 500, 550, 600, 700, 800, 900, 1000 |

Weight [kg]

| H [mm] | W [mm] | |||||||||||

| 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 700 | 800 | 900 | |

| 200 | 13.3 | 14.2 | 15.1 | 16.1 | 16.9 | 17.7 | 20.7 | 21.7 | 22.7 | 24.8 | 26.8 | 28.9 |

| 250 | 14.2 | 15.2 | 16.1 | 17.2 | 18.1 | 19.1 | 22.2 | 23.3 | 24.5 | 26.7 | 28.9 | 31.2 |

| 300 | 15.1 | 16.1 | 17.2 | 18.4 | 19.3 | 20.4 | 23.8 | 25.0 | 26.2 | 28.6 | 31.0 | 33.4 |

| 350 | 16.1 | 17.2 | 18.4 | 19.7 | 20.7 | 21.9 | 25.5 | 26.8 | 28.1 | 30.7 | 33.3 | 35.9 |

| 400 | 16.9 | 18.1 | 19.3 | 20.7 | 21.8 | 23.0 | 26.9 | 28.3 | 29.7 | 32.4 | 35.2 | 37.9 |

| 450 | 19.7 | 21.1 | 22.6 | 24.2 | 25.5 | 27.0 | 28.5 | 29.9 | 31.4 | 34.3 | 37.3 | 40.2 |

| 500 | 20.7 | 22.3 | 23.8 | 25.5 | 26.9 | 28.5 | 30.0 | 31.6 | 33.1 | 36.2 | 39.3 | 42.4 |

| 550 | 21.8 | 23.4 | 25.0 | 26.8 | 28.3 | 30.0 | 31.6 | 33.2 | 34.9 | 38.1 | 41.4 | 44.7 |

| 600 | 22.8 | 24.5 | 26.3 | 28.2 | 29.7 | 31.4 | 33.2 | 34.9 | 36.6 | 40.1 | 43.5 | 47.0 |

| 700 | – | – | – | – | – | – | – | – | 40.1 | 43.9 | 47.7 | 52.5 |

| 800 | – | – | – | – | – | – | – | – | 43.6 | 48.7 | 52.9 | 57.0 |

| 900 | – | – | – | – | – | – | – | – | 48.0 | 52.5 | 57.0 | 61.5 |

| 1000 | – | – | – | – | – | – | – | – | 51.5 | 56.4 | 61.2 | 66.0 |

| H [mm] | W [mm] | ||||||

| 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | 1600 | |

| 200 | 31.0 | – | – | – | – | – | – |

| 250 | 33.4 | – | – | – | – | – | – |

| 300 | 35.8 | – | – | – | – | – | – |

| 350 | 38.5 | – | – | – | – | – | – |

| 400 | 40.7 | – | – | – | – | – | – |

| 450 | 43.1 | – | – | – | – | – | – |

| 500 | 45.6 | – | – | – | – | – | – |

| 550 | 48.0 | – | – | – | – | – | |

| 600 | 50.4 | – | – | – | – | – | – |

| 700 | 56.3 | 60.1 | 65.8 | 68.6 | 71.5 | 75.3 | 79.1 |

| 800 | 61.2 | 65.3 | 71.5 | 74.5 | 77.7 | 81.9 | 86.0 |

| 900 | 66.0 | 70.5 | 77.2 | 83.9 | 90.8 | 95.3 | 99.8 |

| 1000 | 70.9 | 75.7 | 89.8 | 93,3 | 97.0 | 101.9 | 106.7 |

– = Size not available as standard

Structure and materials

| Number | Part | Material |

| 1 | Casing | Galvanised steel |

| 2 | Blade | Galvanised steel |

| 3 | Inspection hatch covering | Galvanised steel |

| 4 | Operating model (actuator) |

– |

Operating models

Electric actuator

The Halton Sec SFR smoke control damper is equipped with an electric actuator, 24 V or 230 V (no spring return or fuse aloud). The actuator is equipped with a visual position indicator and built-in limit switches both open and closed positions.

The smoke control damper must be connected to a common fire alarm or building automation system. It can be used in fully automatic (AA) activation systems.

| Order code | Operating model | Damper sizes (WxH, mm) |

Operating voltage | Limit switch |

| R1 | BEN 24 15 Nm |

200×400 – 1000×600 |

AC/DC 24 V | ✔ |

| R2 | BEN 230 15 Nm |

200×400 – 1000×600 |

AC 230 V | ✔ |

| R3 | BE 24 40 Nm |

600×900 – 1600×800 |

AC/DC 24 V | ✔ |

| R4 | BE 230 40 Nm |

600×900 – 1600×800 |

AC 230 V | ✔ |

| I1 | Schischek InMax 50.75-s 72 Nm |

1200×1000 – 1600×1000 |

24 V / 230 V | ✔ |

Function

The Halton Sec SFR single compartment smoke control damper is CE certified for horizontal duct orientation. It fulfils the fire resistance class up to E600 90 (Ved-i↔o) S 1000C300 AAsingle requirements.

Smoke control dampers allow smoke to be extracted from the single compartment smoke zone by dedicated smoke extraction system. In case of fire sequence of operation is important, smoke extract fans should not be started before the smoke control dampers are opened.

The smoke control damper must be connected to common fire alarm or building automation system. It can be used in fully automatic (AA) activation systems.

The smoke control damper is equipped with an electric actuator 24 V or 230 V (no spring return or fuse aloud). The actuator is equipped with built-in limit switches for both open and closed position.

The actuator has visual position indicator.

Installation

Please see/download Installation Guide for this smoke control damper from section Downloads.

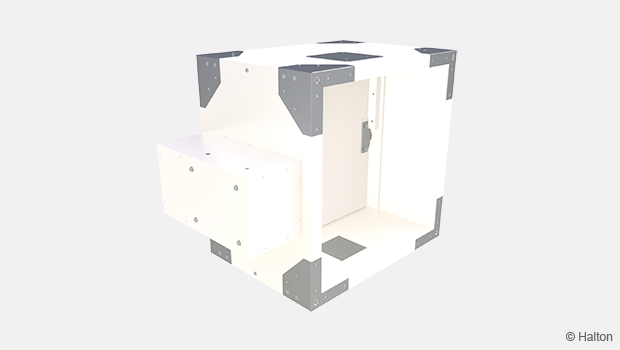

Servicing

No regular maintenance is required for the product.

To ensure proper operation of smoke control dampers, an inspection must be carried out regularly according to local building codes. The minimum recommended inspection period is every 6 months. Documentation of testing must be saved for future needs.

The smoke control damper must be connected to a common fire alarm or building automation system.

The smoke control damper is equipped with two inspection hatches, enabling the possibility to check the position of the damper blade.

Upon failure during testing of the fire damper, maintenance service shall be ordered from an authorised Halton representative to ensure appropriate operation of the product.

Specification

The single compartment smoke control damper is CE certified and marked according to the standard EN 12101-8 and fire tested according to the EN 1366-10 standard.

A smoke control damper of maximum fire resistence class E600 90 (ved-i↔o) S 1000C300 AAsingle requirements.

The smoke control damper casing complies with the tightness requirements for EN 1751 class C. Leakage through closed damper blade fulfils class 2 according to EN 1751.

The smoke control damper can be installed to horizontal smoke extract duct or directly to the end of the smoke extract duct.

The casing of the smoke control damper is made of galvanised steel.

The blade of the smoke control damper is made of fire resistant asbestos free board (mineral fibre).

The actuator is equipped with visual position indicator and built-in limit switches for both open and closed positions.

The smoke control damper is equipped with two inspection hatches.

Order code

SFR-W-H; MA-OP-ZT

W = Width of duct connection [mm]

200, 250, 300, 350, 400, 450, 500, 550, 600, 700, +100, …, 1250

H = Height of duct connection [mm]

200, 250, 300, 350, 400, 450, 500, 550, 600, 700, 800, 900, 1000

Other options and accessories

MA = Material

GS Galvanised Steel

OP = Operating models

R1 BEN24, 24 V, 15 Nm

R2 BEN230, 230 V, 15 Nm

R3 BE24, 24 V, 40 Nm

R4 BE230, 230 V, 40 Nm

I1 Inmax 50.75-S, 75 Nm

ZT = Tailored product

N No

Y Yes (ETO)

Order code example

SFR-300-300, MA=GS, OP=R2, ZT=N

Downloads

-

Halton Sec SFR – Smoke control damper (AAsingle)

Data

en

-

Halton Sec SFR – Savunhallintapelti (AAsingle)

Data

fi

-

Halton Sec SFR – Rökkontrollspjäll (AAsingle)

Data

se

-

Installation guide – Halton Sec SFR

Data

English (en) -

Declaration of Performance (DoP) – Halton Sec Fit Rectangular (SFR)

Data

en_GB -

Construction Product Regulation (CPR) – SFR

Data

en_GB

"*" indicates required fields