Product / CPA

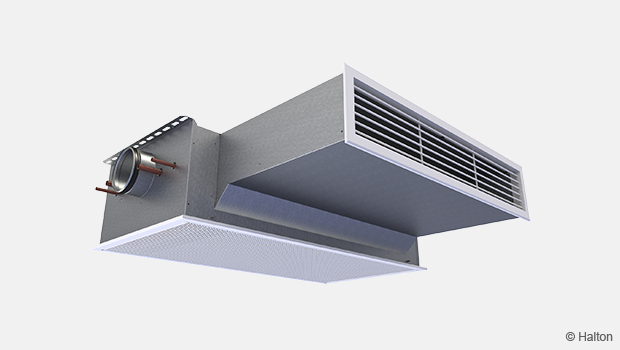

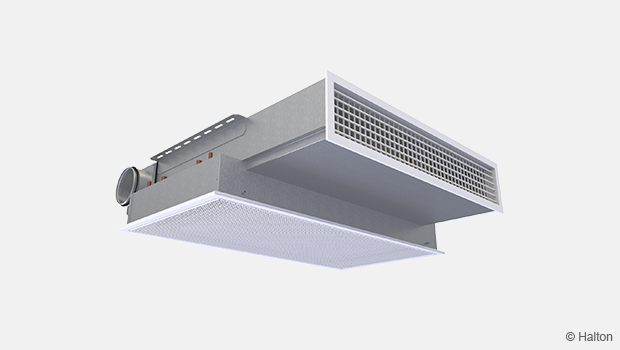

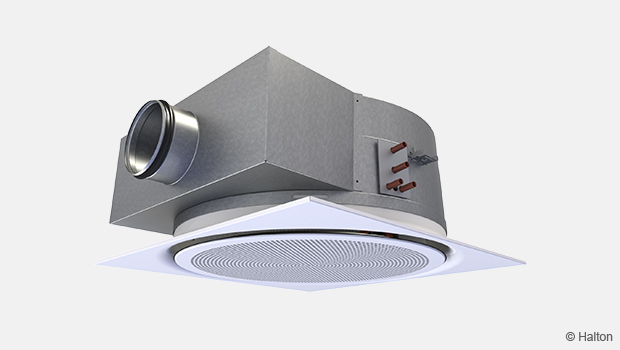

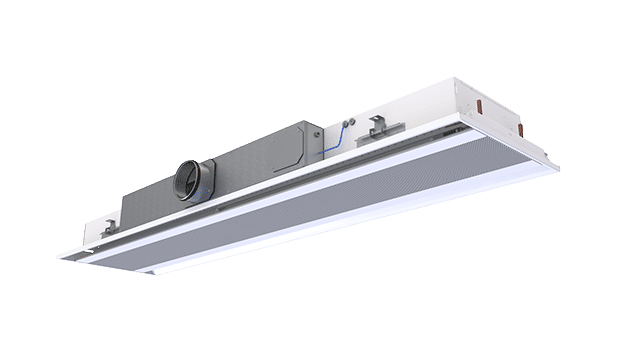

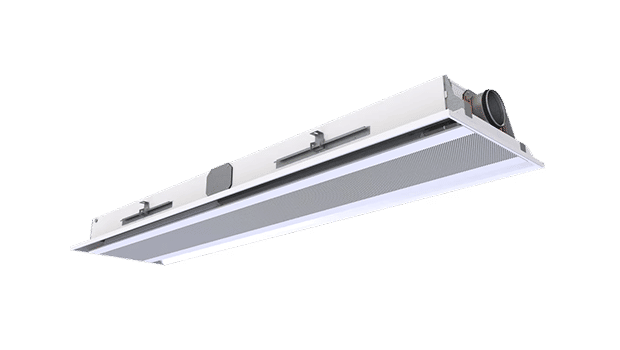

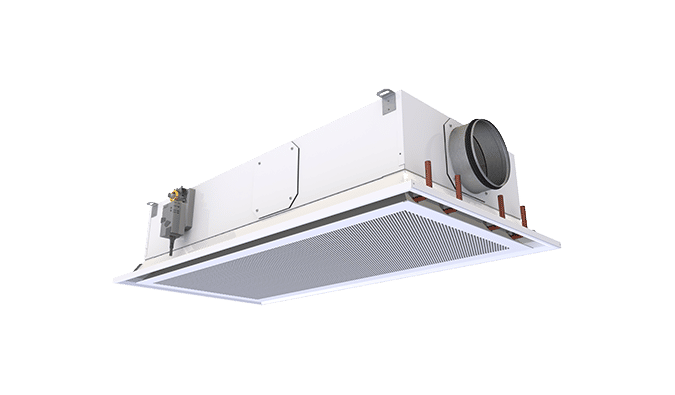

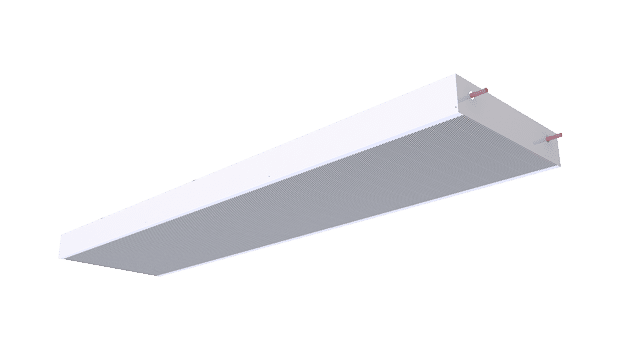

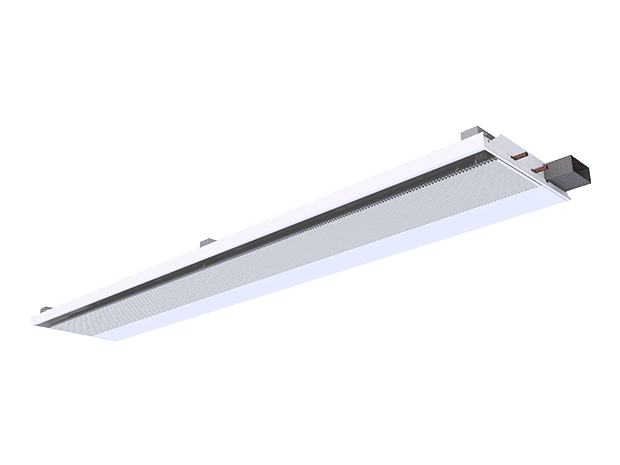

Halton CPA – Passive chilled beam

Low life cycle cost unit for suspended installation.

- Modular convector for mounting flush or below the ceiling plane

- Suitable for offices, conference rooms, retail and hotels

Overview

- Modular convector for mounting flush or below ceiling plane

- Quiet operation

- No moving parts

- Long maintenance interval to meet low life cycle cost

- Individual/multiple beam control

- Suitable for offices, conference rooms, retail, hotels and healthcare environments

- Can be delivered with water valve

- Two heights to meet cooling demands 100mm and 300mm

Halton chilled beams are certified by Eurovent Certita.

Dimensions and weight

WD = Location of pipe connection

S Front end

U On top

| W | H | w | L | l (without valves) | l (with valves) |

| 315 | 100 | 136 | 1200-5000 | L-200 | L-300 |

| 450 | 100 | 204 | 1200-5000 | L-200 | L-300 |

| 585 | 100 | 271 | 1200-5000 | L-200 | L-300 |

| 315 | 300 | 136 | 1200-5000 | L-200 | L-300 |

| 450 | 300 | 204 | 1200-5000 | L-200 | L-300 |

| 585 | 300 | 271 | 1200-5000 | L-200 | L-300 |

A coil with 1 loop has a connection pipe ØD 15 mm and 2 loops has a connection pipe ØD 22 mm.

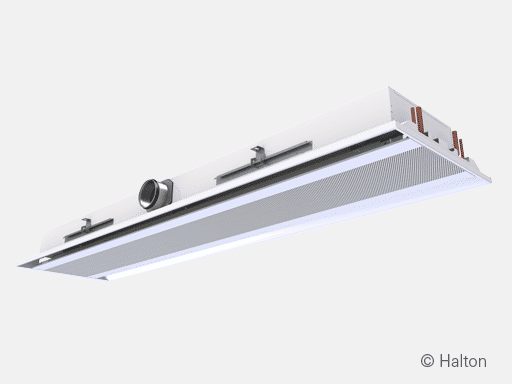

Fig.1. Optionality factory-fitted valve

Weights, kg/m (including water)

| Width | Height 100 mm |

Height 300 mm |

| 315 | 8.5 (8.7) | 9.7 (10.0) |

| 450 | 11 (12.1) | 12,4 (13.5) |

| 585 | 13 (14.4) | 14,4 (15.8 |

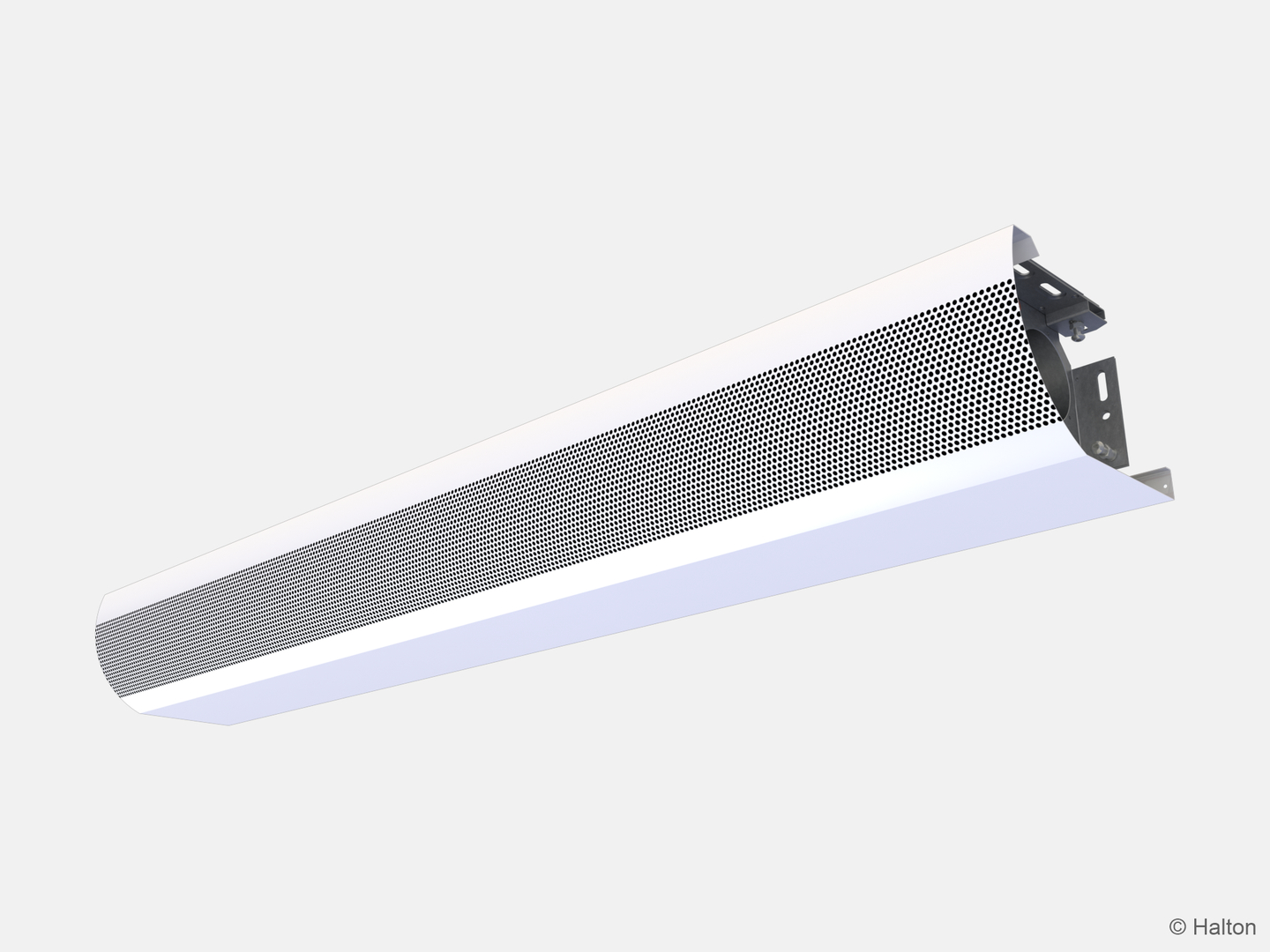

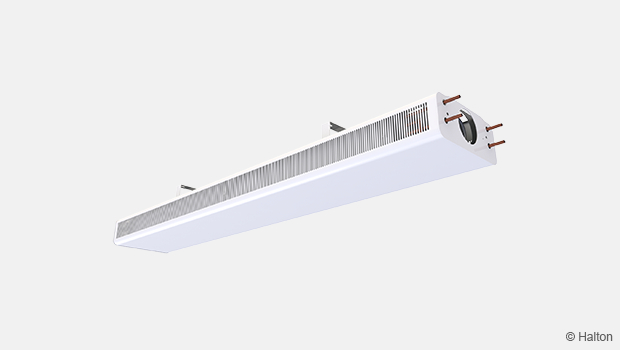

Material

Halton CPA has side flanges made from steel The modular perforated screen (holes 10 mm / 50% free area) is produced in pre-painted sheet metal, RAL 9003 (20% gloss). The coil is made from Ø15 mm copper pipes bonded to aluminum fins.

| Part | Material | Finishing | Note |

| Side flanges | Sheet metal | Painted | – |

| Perforated screen | Sheet metal | Painted | – |

| End cap | Sheet metal | Painted | – |

| Coiling fins | Aluminium | – | – |

| Cooling pipes | Copper | – | Diameter 15 mm |

Accessories

| Accessory | Code | Note |

| Pipe connection, straight in the end | WD=S | |

| Pipe connection, at the top | WD=U | |

| Factory-fitted control valve | CV = | See Order Code |

Other options by requesting Halton customer service.

Function

The passive beam operates by natural convection, removing the heat load from the room and replacing it with a cooling airflow. The convective airflow (output) increases or decreases in proportion with the heat load within the occupied zone, securing an optimal thermal comfort. Varying sensible cooling output requirements are met by regulating the flow of chilled water through the beam heat exchanger. This is controlled by a combination of room thermostat and water valve. Operating at elevated chilled water temperatures (to avoid latent cooling), the opportunities for free-cooling are significant.

Installation

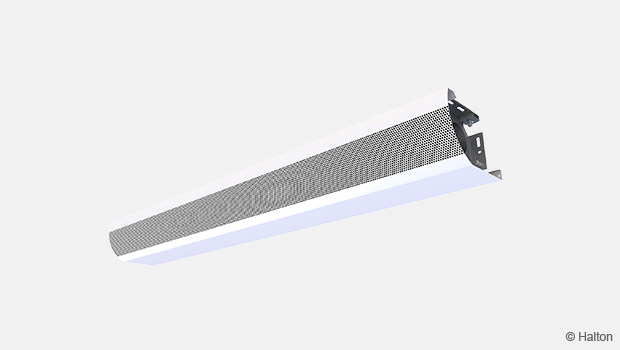

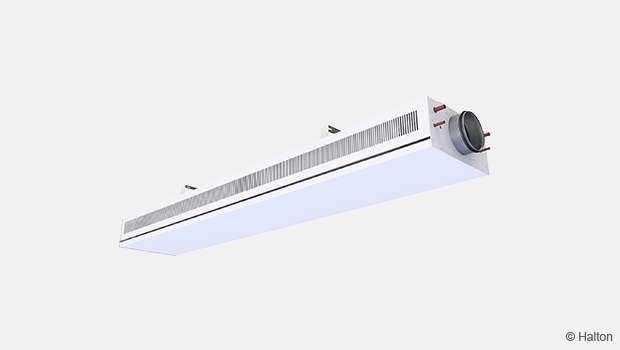

The chilled beam Halton CPA is installed fully exposed below a ceiling or suspended ceiling.

In order to ensure effective convection, the beam should be mounted at a minimum distance from the ceiling equal to 0.25 x the width of the beam, when installed away from wall surfaces, or 0.5 x beam width when installed close to partition walls.

Each chilled beam is fixed to the ceiling with expansion anchors and threaded drop rods (not included in the delivery). Four assembly brackets are fixed one fifth of the unit length (L/5) away from the end of the beam. There will be six assembly brackets with beam length ³ 3500.

The exact positions of the brackets are adjusted according to the rod position.

The chilled beam position can be easily adjusted both horizontally and vertically. Assembly brackets are supplied as standard in the package.

The contractor shall supply threaded rods and expansion anchors.

Distance from the ceiling

D = distance wall; up to 1,0 x W

Adjustment

Commissioning of the chilled beam system is carried out following standard practice:

- Fill up and flush the main pipelines

- Fill up and vent the beam circuits

- Adjust the flow water temperature set point

- Adjust water flow rates with the balancing valves in all main pipelines to the correct value

- Adjust water flows in all chilled beams to the correct value

Servicing

The Halton CPA chilled beam requires minimum maintenance. It may be necessary to clean the cooling coils every three to five years, depending on room conditions and air quality. The casing may be cleaned with a damp cloth. The cooling coil can be cleaned using a vacuum cleaner.

Specification

Output/capacity 80 500 W/m

Standard length 1200, +100,…,5000 mm

Width 315, 450 or 585 mm

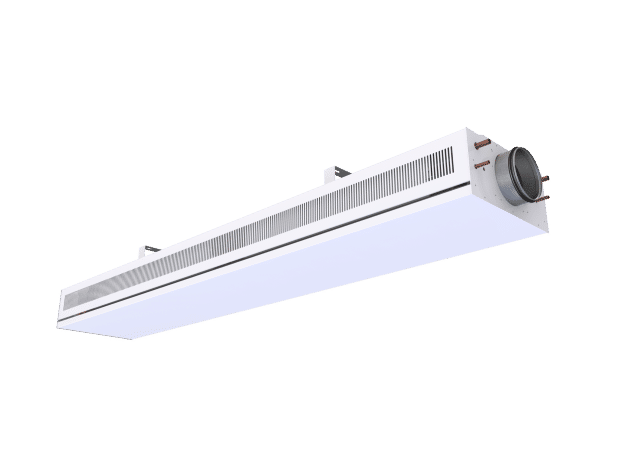

Casing height 100 or 300 mm

The heat exchanger is constructed from aluminium fins and copper pipes with a nominal outside diameter of 15 mm.

The maximum chilled water pipe work operating pressure is 1.0 MPa. All joints are fully soldered and factory pressure tested.

Order code

CPA-H-L-W-NW; CO-WD-CV-VA-ZT

H = Height (mm)

100, 300

L = Length (mm)

1200,+100,…, 5000

W = Width (mm)

315, 450, 585

NW = Number of water loops

1, 2

Other options and accessories

CO = Colour

SW Signal white (RAL9003)

X Special colour (RALxxxx)

WD = Location of pipe connection

S Front end

U On top

CV = Control valve

N No

A1 Adjust. kv value, factory mounted, no actuator

A3 Adjust. kv value, factory mounted, 24-V actuator

A5 Adjust. kv value, factory mounted, 230-V actuator

A7 Constant-flow-mounted, no actuator

A9 Constant-flow-mounted, 24-V actuator

A11 Constant-flow-mounted, 230-V actuator

VA = Visual appearance

A Square edge

ZT = Tailored product

N No

Y Yes (ETO)

Code example

CPA-100-1200-315-1, CO=SW, WD=S, CV=N, VA=A, ZT=N

Downloads

"*" indicates required fields