Product / R6W

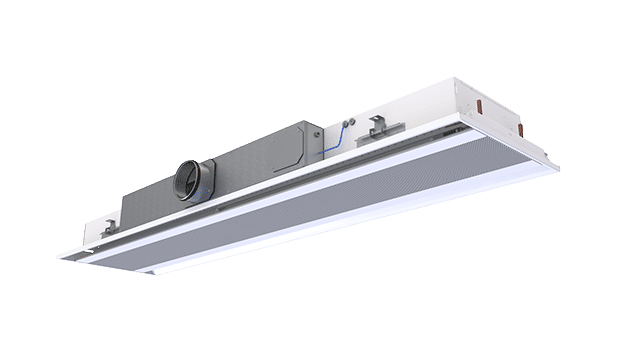

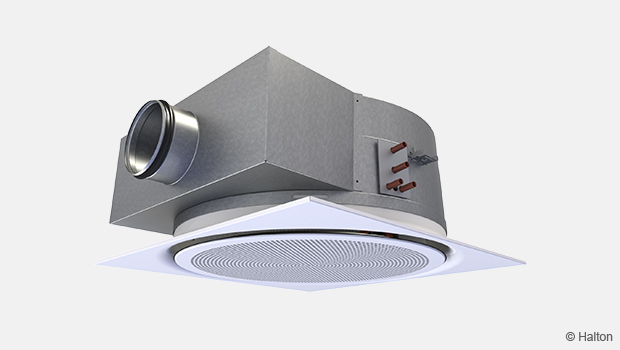

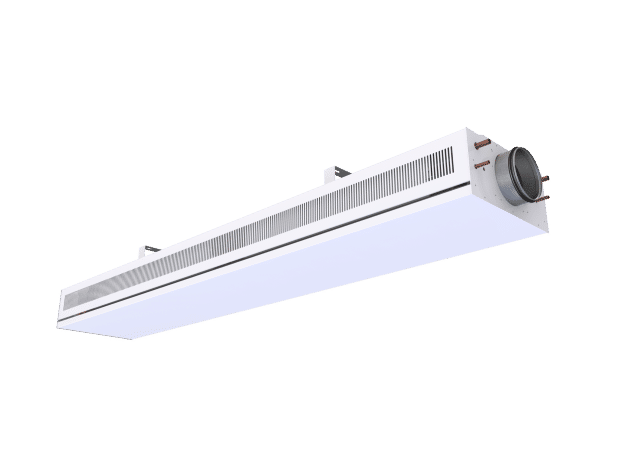

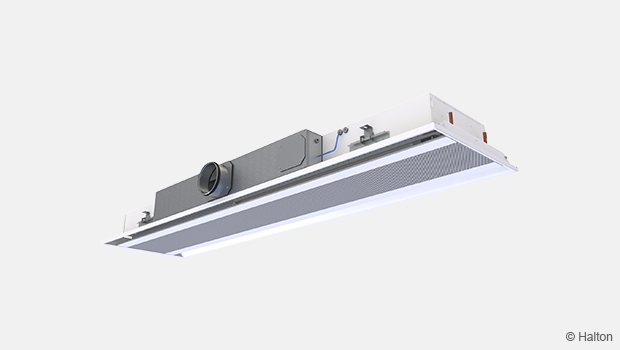

Halton Rex R6W – Variable air volume chilled beam (VAV)

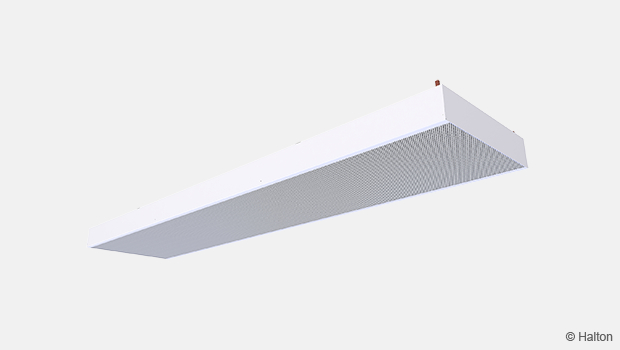

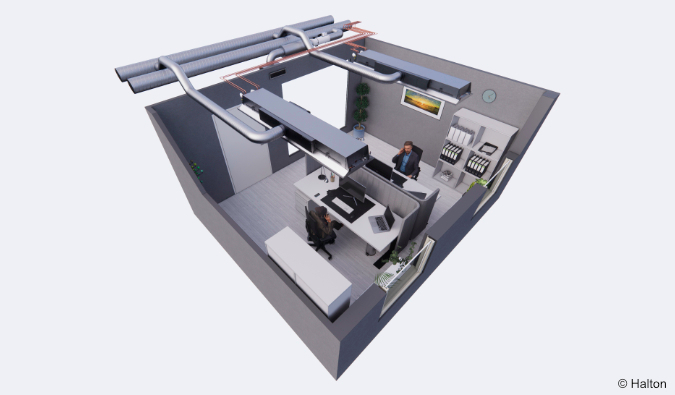

Halton Rex R6W is a variable air volume chilled beam that combines the efficiency of chilled beams and variable airflow control to optimise thermal comfort and energy efficiency. It is an advanced system designed for energy efficiency and demand-controlled ventilation in buildings. Particularly, it is effective in applications that prioritise high-quality indoor conditions, energy-efficient operation, and individual room control. It contributes to sustainable performance by helping reduce its carbon footprint, which impacts the environment throughout its lifecycle.

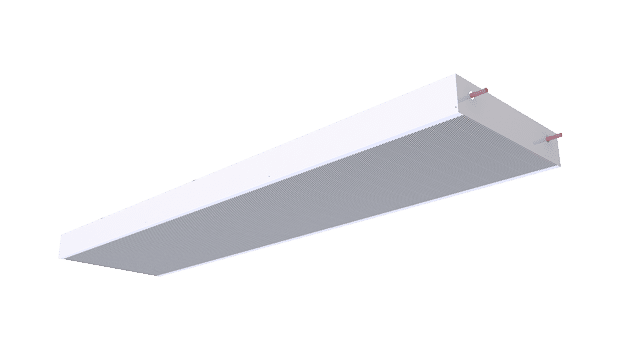

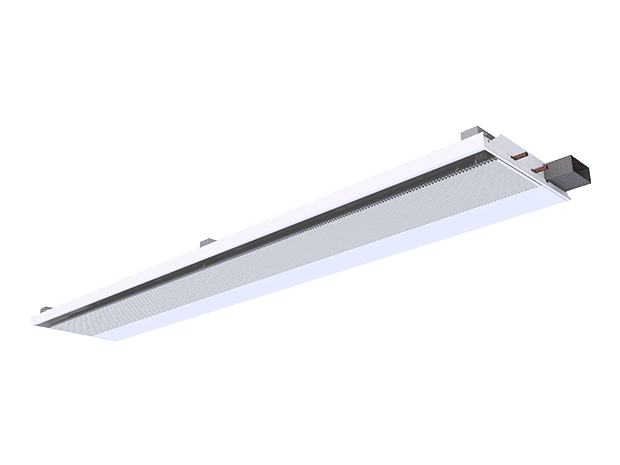

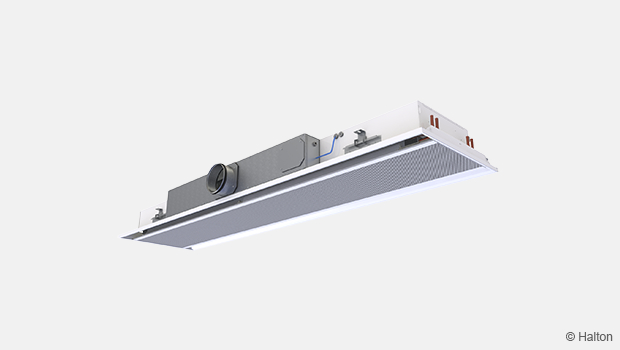

- Combines cooling, heating, and supply air unit for flush installation within a suspended ceiling.

- In-built flexibility for partition wall relocations with Halton Velocity Control (HVC).

- Adjustable supply airflow rate changes with Operation Mode Damper (OMD).

- Two product models with adjustable airflow using motorised VAV.

- A model with a room automation system package.

Overview

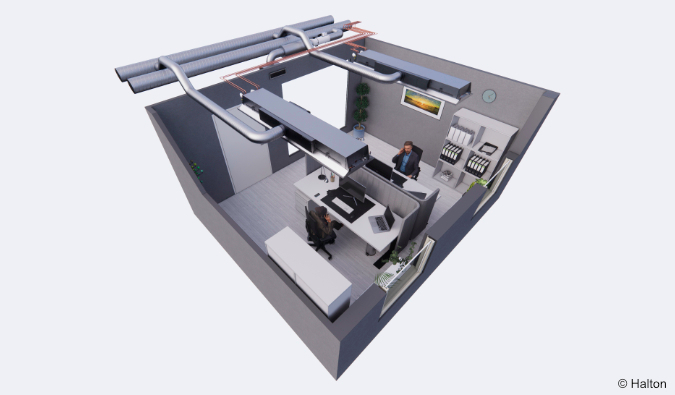

The Halton Rex R6W chilled beam is a versatile product designed for demand-based ventilation systems. It serves as a combined cooling, heating, and supply air unit, ideal for flush installation within a suspended ceiling. Its compatibility with both pressure-dependent constant static pressure ductwork and pressure-independent ductwork makes it well-suited for demand-based ventilation. It is particularly effective in applications that prioritize high-quality indoor conditions, energy-efficient operation, and individual room control.

Halton Rex R6W chilled beam is designed for high-quality office requirements with high flexibility of airflow adjustability. The operation of this chilled beam will adapt to changes in the use of the space and office layout changes.

Application areas

- Office rooms

- Public spaces

- Landscape offices and meeting rooms

Key features

- Easy and fast selection with Halton eHIT design tool

- In-built flexibility for partition wall relocations with Halton Velocity Control (HVC).

- Adjustable supply airflow rate changes with Operation Mode Damper (OMD).

- Combined cooling, heating, and supply air unit for flush installation within a suspended ceiling.

- Well suited for spaces with high cooling loads, low humidity loads, and demand-based ventilation requirements.

-

Enhanced life cycle performance with optimised air and water flow rates.

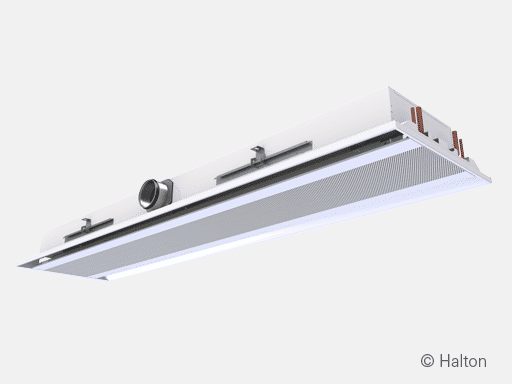

- Two product models with adjustable airflow using manual CAV or motorised VAV.

- Flexible model with 0-100% airflow control and pressure-dependent operation.

- Autonomic model with 0-100% airflow control and pressure-independent operation.

- Ideal solution for applications where high-quality indoor conditions, energy-efficient operation and individual room control are appreciated.

- A model with Halton Workplave WRA room automation system package available.

Operating principle

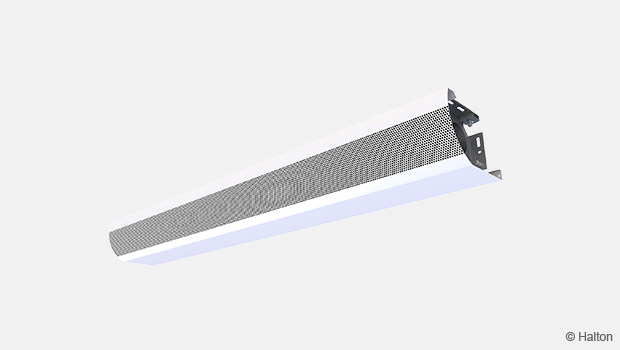

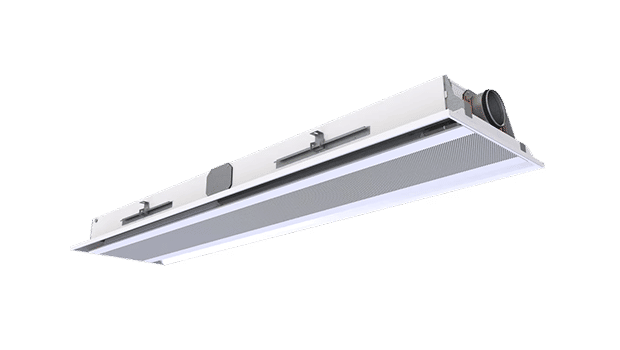

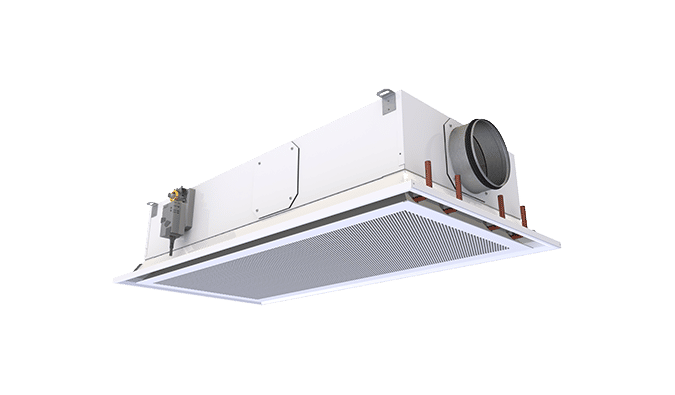

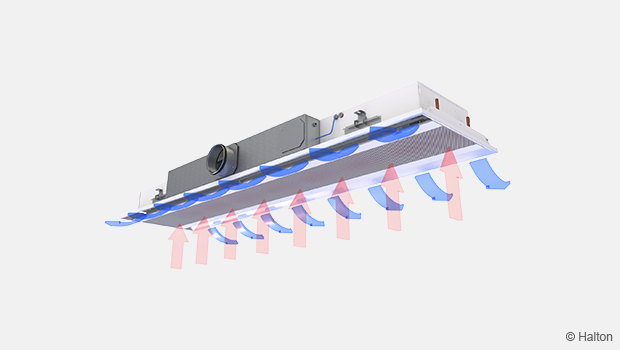

Installation of Halton Rex R6W chilled beam flush with a suspended ceiling.

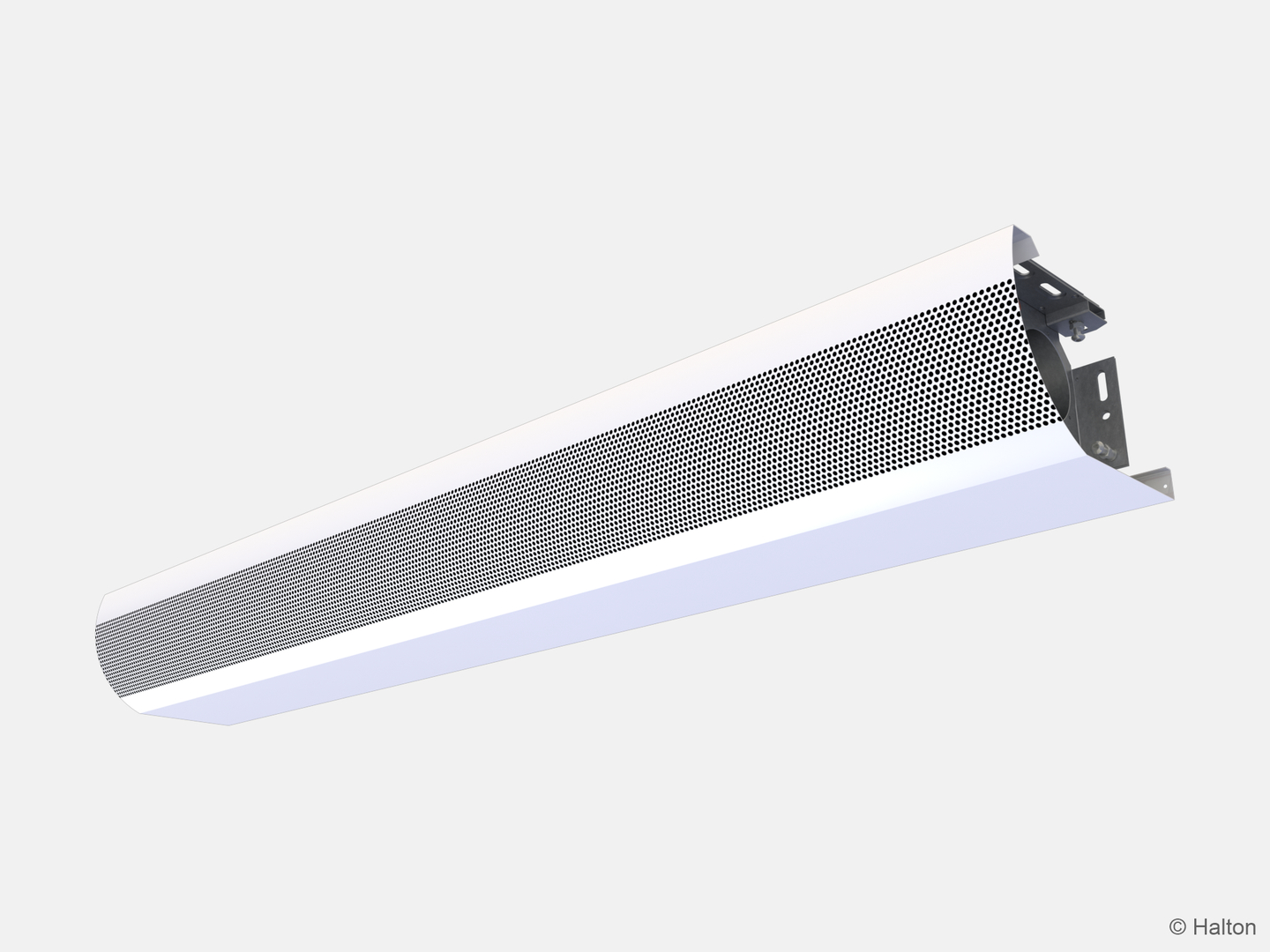

The primary supply air enters the plenum of the active chilled beam. From there, it is diffused into the room through nozzles controlled by the Operation Mode Damper (OMD).

The supply air nozzle jets efficiently induce ambient room air, which is directed horizontally along the ceiling surface. The secondary air is drawn through the perforation located at the bottom of the beam. Then, the air is cycled through the heat exchanger, where it is either cooled or heated before being diffused into the room.

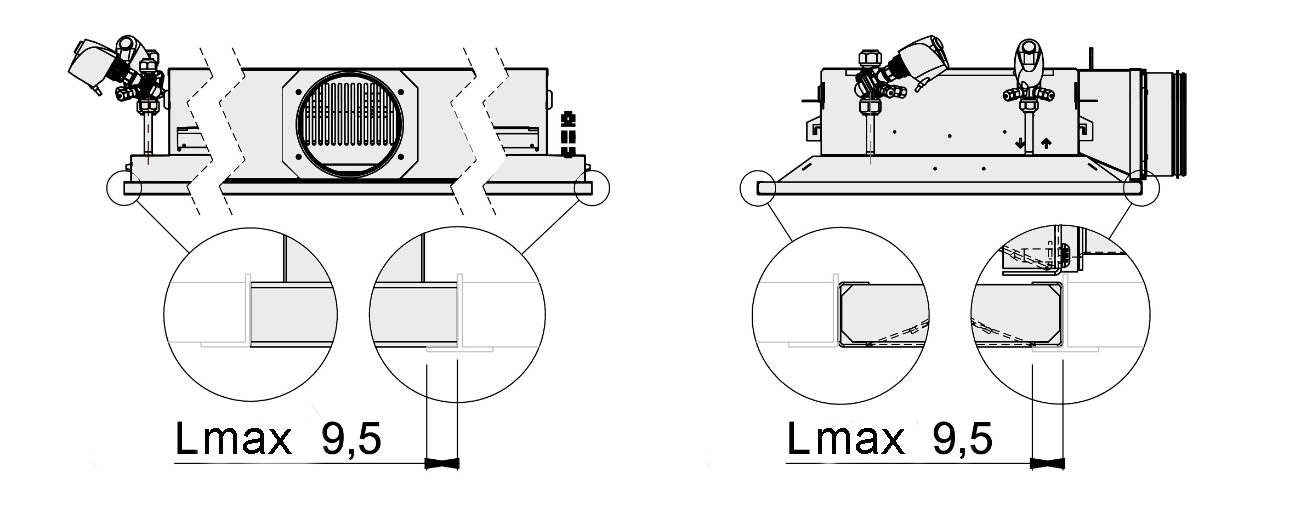

Velocity control in the occupied zone

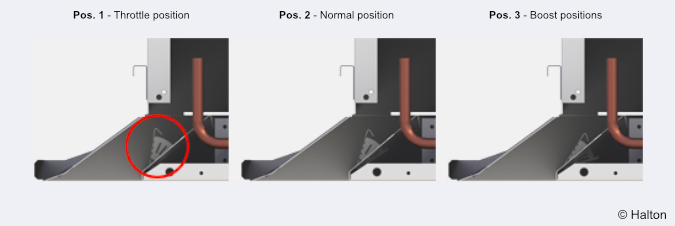

The Halton Velocity Control (HVC) is used to adjust room air velocity conditions either when the room layout is changed, (e.g., in cases where the chilled beam is located near the partition wall) or when local, alter the individual velocity conditions. The HVC adjustment impacts the induced room airflow through the heat exchanger. Therefore, it either increases or decreases both the velocities in the occupied zone and the cooling/heating capacity of the chilled beam.

The HVC involves manual velocity adjustment in three different positions 1 = Throttle, 2 = Normal, and 3 = Boost, as shown in Fig. 2. The HVC system is divided into sections to enable the adjustment of conditions in different parts of the occupied zone. Depending on the length of the beam, the optimal HVC damper module lengths are between 500 and 1400 mm.

The HVC damper is divided into sections (Pos. 1-3) to enable the adjustment of conditions in different parts of the occupied zone.

It is recommended to design the chilled beam in the normal position, to allow both throttle and boost functions during the building’s life cycle.

Supply airflow control

The supply airflow of the chilled beam nozzle jets is dependent on the nozzle type, nozzle row length and static chamber pressure.

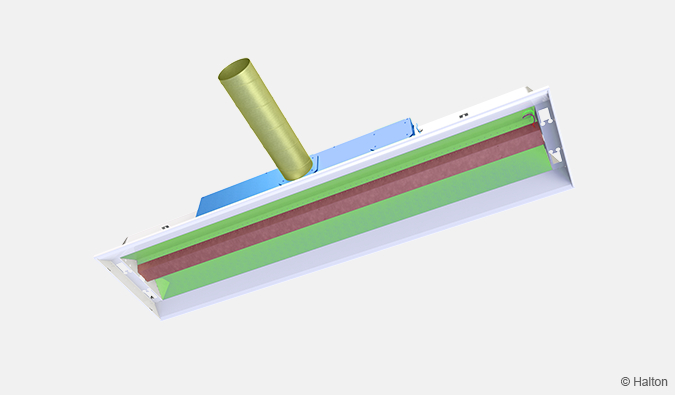

The Operation Mode Damper (OMD), blue in Fig. 3, adjusts and controls the fresh airflow rate in a room, either manually or by electric actuator. The airflow rate is dependent on the opening position of the OMD damper. The occupancy sensor monitors the room’s operation mode.

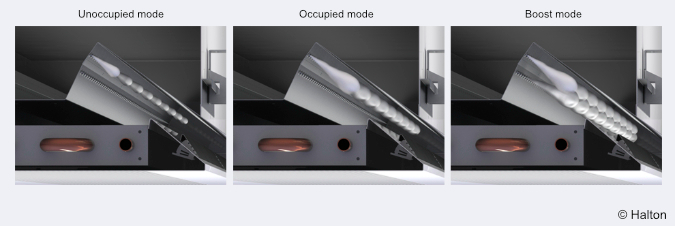

The figure below (Fig. 4.) presents the function in different modes controlled by the OMD.

-

Unoccupied mode: In this mode, supply air rate is set to a minimum value that can remove material emission.

-

Occupied mode: In this mode, set the supply air rate to normal office mode.

-

Boost mode: When more persons are in the space, based on the CO2 sensor, airflow is increased to boost mode to maintain the set target value of indoor air quality.

Chilled beams for demand-based airflows can be connected to any kind of duct work zones. Constant pressure ductwork zone gives advantages for easier design and operation.

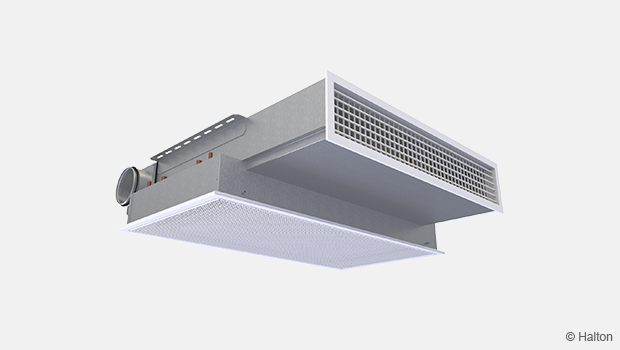

Flexible model

Flexible model with 0-100% supply airflow control and pressure dependent operation

The Halton Operation Mode Damper (OMD) in the Halton Rex R6W Flexible model is used for manual supply airflow adjustment or motorised Variable Air Volume (VAV) control of the supply airflow rate.

The OMD control can be used as a Constant Air Volume (CAV) damper. That is, it can adjust the k-factor to achieve the correct airflow with a certain pressure level. It removes the need for changing or plugging the nozzles of the Halton Rex R6W chilled beam supply air control.

When OMD control is equipped with a motorised actuator, fully flexible VAV control is achieved. It allows different pressure-dependent VAV modes, with minimum, normal, and boost airflow settings, for instance.

It is recommended that Halton Rex R6W Flexible model chilled beams for demand-based airflows be connected to a constant-pressure ductwork zone.

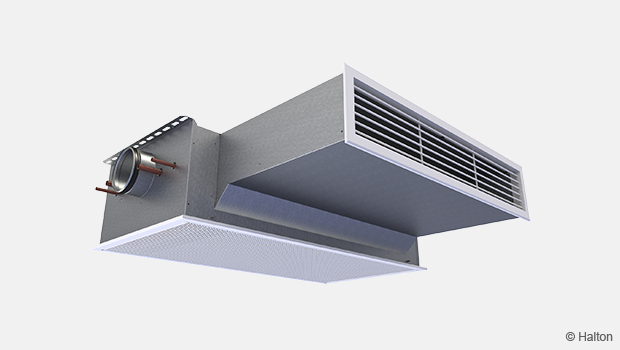

Autonomic model

Autonomic model with 0-100% supply airflow control and pressure independent operation

The Halton Operation Mode Damper (OMD) in the Halton Rex R6W Autonomic model is used for manual supply airflow adjustment or motorised Variable Air Volume (VAV) control of the supply airflow rate. In the Halton Rex R6W Autonomic model, when the OMD control is equipped with a motorised actuator integrated with pressure measurement, fully flexible VAV control with pressure-independent operation is achieved. It allows different pressure-independent VAV modes with, for instance, minimum, normal, and boost airflow settings.

Halton Rex R6W Autonomic model chilled beams can be used in any type of ductwork zone. The design of a chilled beam should ensure both minimum and maximum ductwork pressure levels with variable pressure levels in the ductwork.

Temperature control

Regulating the water flow rate controls the cooling and heating capacities of the chilled beam according to the control signal of the room temperature controller.

In heating mode, it is recommended that the temperature difference between the jet outlet and room air be no greater than 3 °C. The inlet water temperature of the heat exchanger should also be no higher than 35 °C. Optimal heating performance requires an appropriate primary airflow rate. Thus, the air handling unit shall operate during heating periods to ensure proper heating performance.

Features and options

| Accessory / mode | Code | Description | Note |

|---|---|---|---|

| Combined cooling and heating coil | TC = C | Coil with cooling water circulation | Cooling copper water pipe connections are Ø 12 mm with normal pressure drop (see “Dimensions and weight” section) and Ø 15 mm with low pressure drop. |

| TC = H | Coil with both cooling and heating water circulation | Cooling and heating copper water pipe connections are Ø 12 mm with normal pressure drop. With low pressure drop, cooling water pipe connection is Ø 15 mm and heating Ø 12 mm. (see “Dimensions and weight” section) |

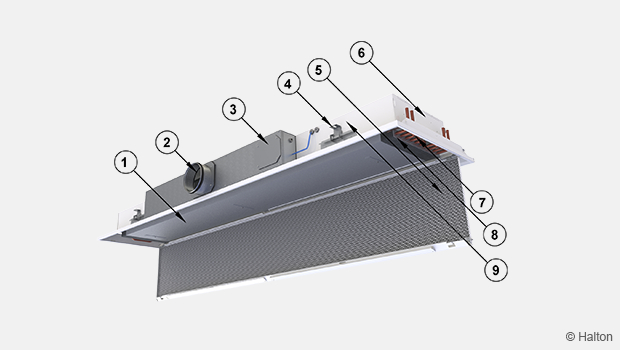

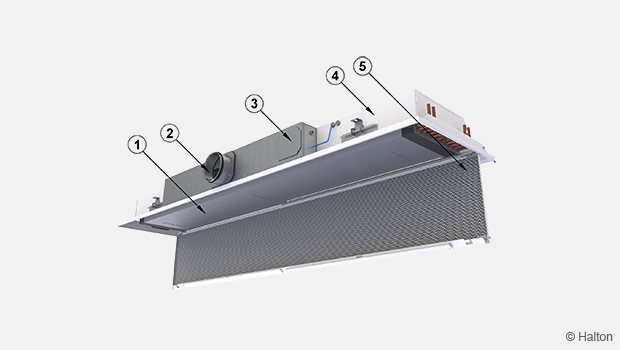

Structure and materials

| No. | Part | Material | Description | Note |

|---|---|---|---|---|

| 1 | Heat exchanger | Galvanised steel | – | – |

| 2 | Supply air connection | Galvanised steel | – | – |

| 3 | Operation mode damper | Galvanised steel | – | – |

| 4 | Brackets | Aluminium | – | – |

| 5 | Front panel 1 | Pre-painted galvanised steel | Polyester-painted, white (RAL 9003, 20% gloss) | Special colours available, Polyester-epoxy-painted |

| 6 | End plates | Galvanised steel | Polyester-painted, white (RAL 9003, 20% gloss) | Special colours available |

| 7 | Coil pipes | Copper | – | – |

| 8 | Coil fins | Aluminium | – | – |

| 9 | Side plates | Pre-painted galvanised steel | Polyester-painted, white (RAL 9003, 20% gloss) | Special colours available, Polyester-epoxy-painted |

Cooling/heating water pipe connections are Cu12 with wall thickness of 0.9-1.0 mm fulfilling European Standard EN 1057:1996.

The maximum chilled/hot water circuit operating pressure is 1.0 MPa.

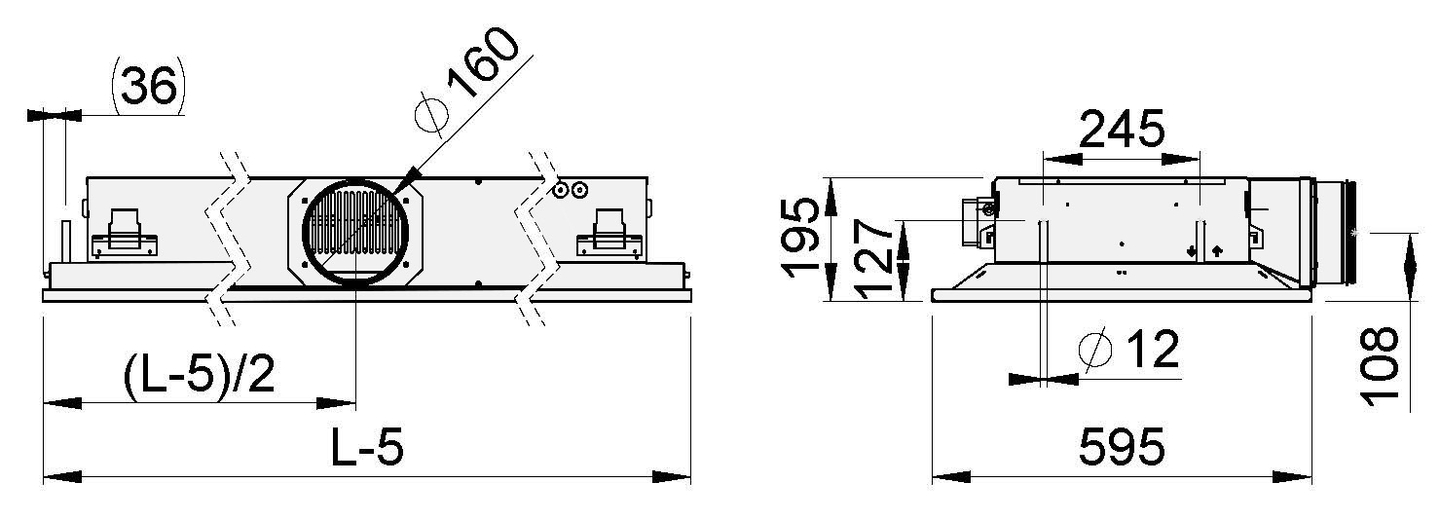

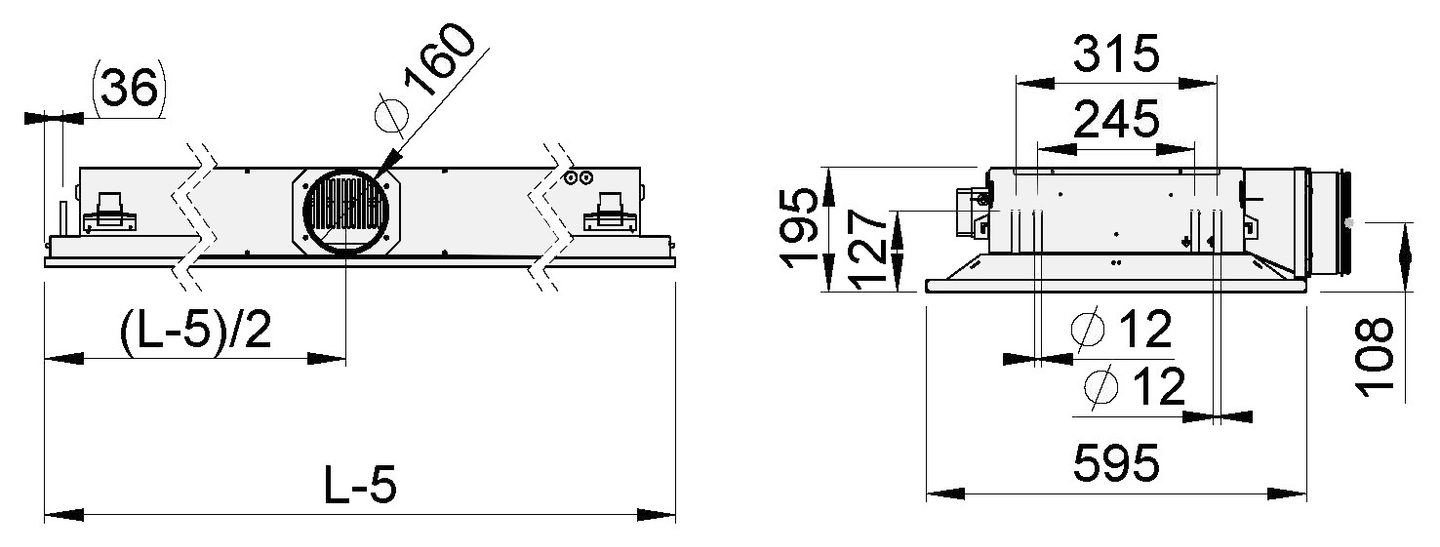

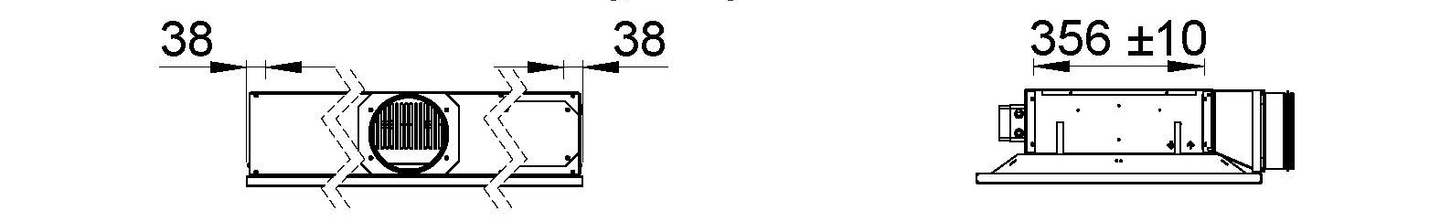

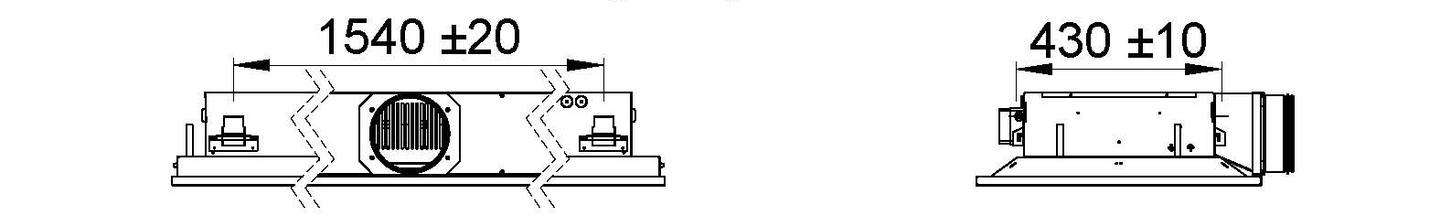

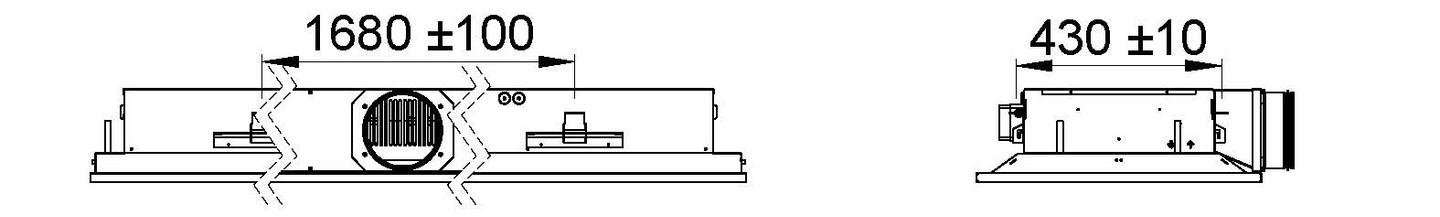

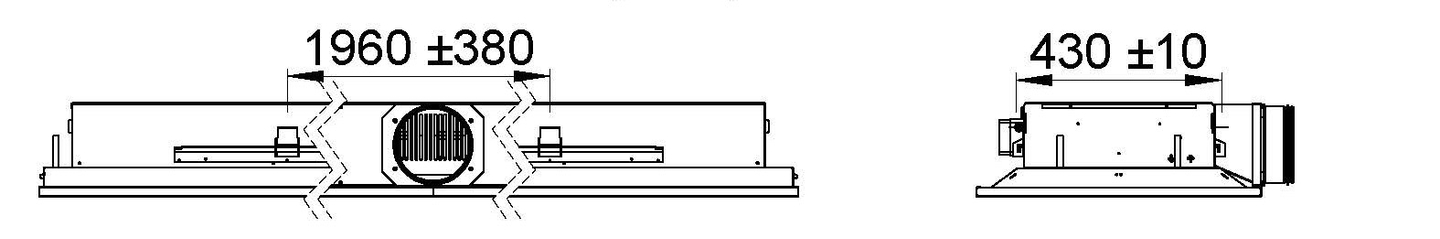

Dimensions and weight

| ØD | Coil length [mm] | Length L-5 [mm] | Weight [kg/m, water excluded] |

|---|---|---|---|

| 160 | 1000, +600, …, 3400 | 1195, +600, …, 3595 (+1715) | 15 |

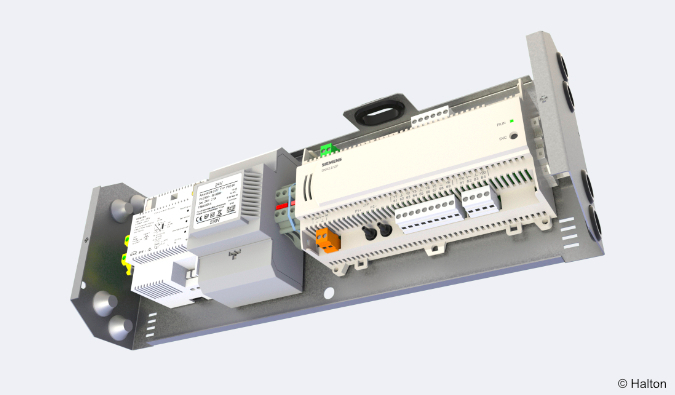

System package

If required, the system package includes a valve with actuator, controller, humidity sensor, CO2 sensor, and temperature sensor.

Halton Workplace WRA automation

Halton Workplace WRA room automation system package for Halton Rex R6W.

Halton Workplace WRA is part of the Halton Workplace solution offering.

Halton Workplace WRA is a controller specially designed to control the automation system of office spaces and meeting rooms. It controls ventilation airflow, room temperature, and indoor air quality.

Halton Workplace WRA room automation package consists of a controller unit and optional components depending on customer needs: a wall panel and sensors for temperature, CO2, occupancy, pressure, and condensation.

Depending on the number of controls and sensors required, the controller unit and wall panel are available in options. The Halton Workplace WRA room automation controller is always combined with other Halton products for an adaptable and high-level indoor climate.

Application area

- Controlling the ventilation airflow, room temperature, and indoor air quality in office spaces and meeting rooms

- The Halton Workplace WRA room automation controller is an essential part of the Halton Workplace system, controlling room units and airflow control dampers.

- Overall Halton Workplace system includes the following:

- Room air conditioning applications with Halton Workplace WRA room automation controller:

- Active chilled beams

- Exhaust units

- VAV dampers

- Active VAV diffusers

- Room air conditioning applications with Halton Workplace WRA room automation controller:

- Halton Max MDC zone control dampers

- Halton Workplace WSO system optimiser

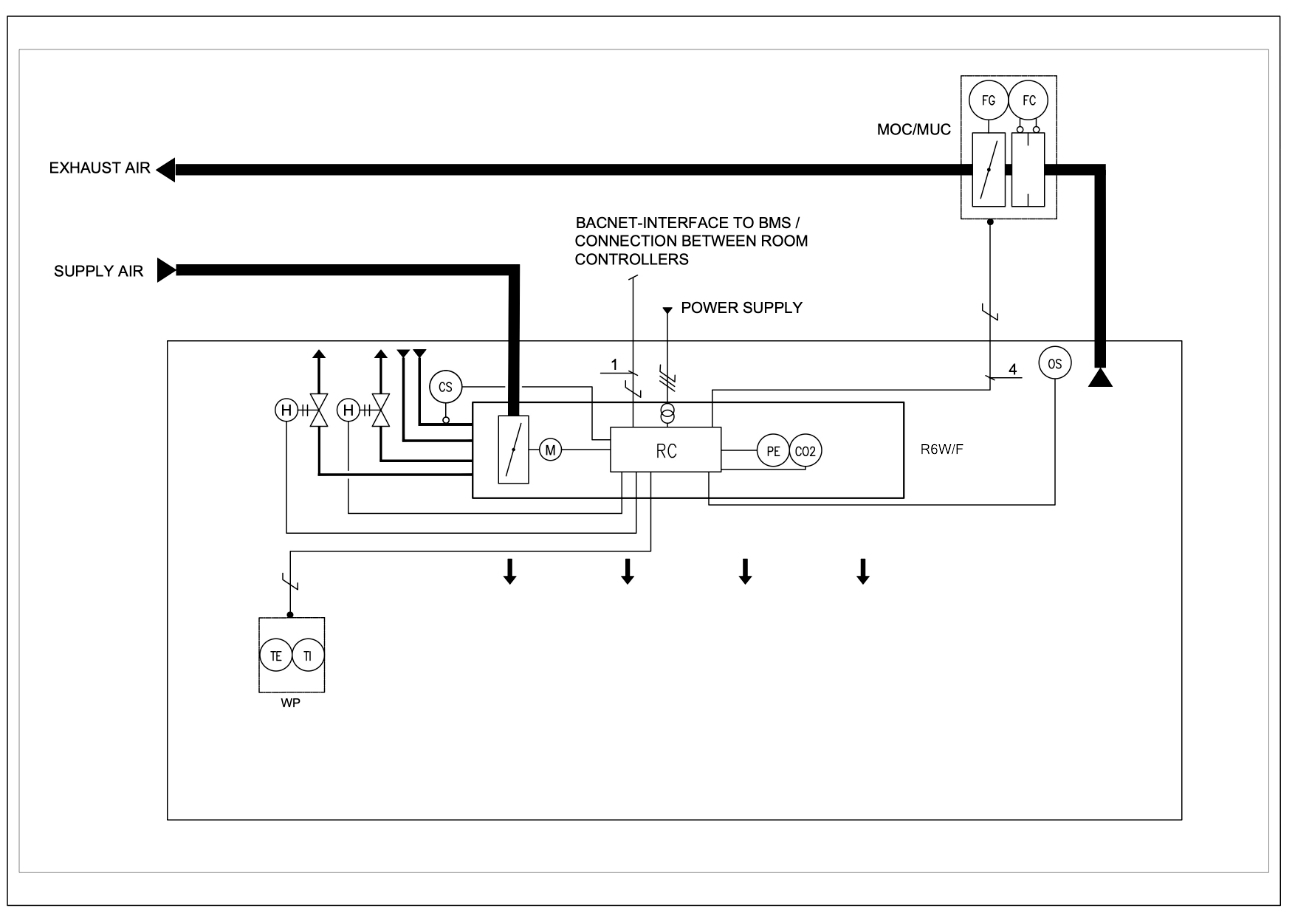

Operating principle

The Halton Workplace WRA room automation controller operates with the Halton Workplace system’s Variable Air Volume (VAV) dampers and active chilled beams. These dampers adjust ventilation airflow, room temperature, and indoor air quality in office spaces.

Each room unit in an office space can have its own dedicated Halton Workplace WRA room automation controller, or a single controller can control multiple room units. The Halton Workplace WRA room automation controller can automatically adjust the system according to users’ preferred indoor environment level, bringing maximum flexibility.

Room automation: Halton Rex R6W active chilled beams controlled with Halton Workplace WRA room automation controllers

Room automation

In this configuration, two Halton Workplace WRA room automation controllers (DXR2.E12P-102A) control two Halton Rex R6W active chilled beams. Each chilled beam has heating and cooling valves, a motorised Operation Mode Damper (OMD) control, and integrated CO2 and condensation sensors. Halton Workplace WRA room automation controller has an integrated pressure sensor. The system also includes an exhaust VAV damper and a wall panel (QMX3.P37) with a temperature sensor and display. One Halton Workplace WRA room automation controller can individually control up to four terminal units, and there can be several Halton Workplace WRA room automation controllers in the room.

Design criteria for room automation

- Halton Rex R6W chilled beam has motorised OMD control

- Condensation and CO2 sensor integrated into Halton Rex R6W chilled beam

- Exhaust airflow control

- Wall panel with temperature sensor and display

- Window switch control

- Pressure sensor integrated into Halton Workplace WRA room automation controller

Equipment list

| Code | Equipment |

|---|---|

| RC | Controller unit |

| FG | Airflow damper actuator |

| FC | Airflow measurement |

| H | Water valve actuator |

| CS | Condensation sensor |

| OS | Occupancy sensor |

| PE | Pressure sensor |

| CO2 | CO2 sensor |

| WP | Wall panel |

| TE | Temperature sensor |

| TI | Temperature display |

Wiring diagram

For the wiring diagram of this configuration, see the Halton Workplace WRA room automation controller’s product page or the section Product selection examples.

Components and order code examples for the system

- 2 x Active chilled beam: Halton Rex R6W

- R6W-F-2400-C-2100, SP=Y, ED=R3, TC=H, CR=N, CN=M1, CO=SW, ZT=N

- 1 x Exhaust unit: Halton AGC Exhaust grille + Halton PRL Plenum for grilles

- AGC-N-400-100 FS=CL, ME=A, FI=PN, CO=W, ZT=N + PRL-F-400-100-160

- 1 x VAV damper: Halton Max MUC or Halton Max MOC

- MUC-G-160, MA=CS

- Automation package: 2 x Halton Workplace WRA room automation controller unit with related components

- WRA/R6W-E21-OM-EX4, WP=37, LC=NA, CD=CS, SW=NA, ST=IC, SL=OE, PM=P2, TC=H, CV=SP5, RV=NA, ZT=N

Cooling and heating water valve selection

Do the water valve selection in the Halton Workplace WRA room automation system package. The water valve sizing depends on the number of secondary and primary chilled beam units that a single controller controls. The whole chilled beam group cooling or heating uses one water value to operate one room controller. The water valve is sized for the whole group when there are multiple chilled beams controlled with a single controller unit. There can be one primary chilled beam with a room controller and up to three secondary chilled beams.

See below the Water valve sizing for 1-4 chilled beams.

| Number of chilled beams (pcs.) | Water valve type | Size for cooling (DN) | Size for heating (DN) | Installation |

|---|---|---|---|---|

| 1 | ABQM | DN15 | DN15 | Integrated to chilled beam |

| 2 | ABQM | DN20 | DN15 | Loose |

| 3 | ABQM | DN20 | DN15 | Loose |

| 4 | ABQM | DN25 | DN15 | Loose |

| Number of chilled beams (pcs.) | Water valve type | Size for cooling (DN) | Size for heating (DN) | Installation |

|---|---|---|---|---|

| 1 | VPP46.. | DN15 | DN15 | Loose |

| 2 | VPP46.. | DN20 | DN15 | Loose |

| 3 | VPP46.. | DN20 | DN15 | Loose |

| 4 | VPP46.. | DN25 | DN15 | Loose |

Specification

The active chilled beam has an integral recirculation air path through the perforated front panel. The induced room airflow rate is manually adjustable via three setting positions without influencing the primary air supply flow rate. The airflow rate of the chilled beam is adjustable without plugging or changing the nozzles.

Operating principle

- The chilled beam unit is equipped with a motorised Operation Mode Damper (OMD).

- The beam with adjustable airflow rate has only one duct connection.

- Two product models with adjustable airflow using manual CAV or motorised VAV OMD actuators

- Flexible product model equipped with motorised (0…10 VDC) VAV actuators for 0-100% airflow control and pressure dependent operation

- Autonomic product model equipped with motorised (0…10 VDC or Modbus RTU/BACnet MSTP) VAV actuators for 0-100% airflow control and pressure independent operation

- The primary airflow rate is adjustable in meeting rooms from minimum to maximum (0-100%) when static chamber pressure is kept constant.

- The air supply to the room space is bi-directional.

Structure

- The front panel is openable from either side in order to allow general maintenance and cleaning.

- The front panel is removable without any special tools.

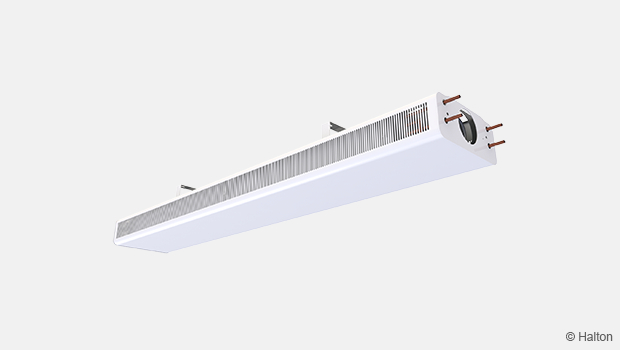

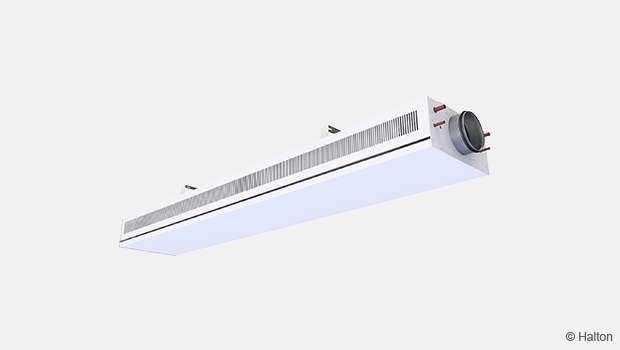

- The active chilled beam is 595 mm wide and 230 mm high.

- The active chilled beam has an inlet duct diameter of 160 mm.

- All pipes are manufactured from copper and connection pipes with a wall thickness of 0.9-1.0 mm.

Material

- The frame, front, and side panels are made of galvanised steel plates.

- All visible parts are white and painted to RAL 9003/20% gloss

- All joints are soldered and factory pressure-tested.

- The pipework’s maximum operation pressure is 1.0 MPa.

- The active chilled beam has measurement taps to allow airflow measurements to all the operation modes.

Packaging and transport

- Active chilled beams are protected by a removable plastic coating.

- The duct connection and pipe ends remain sealed during transport.

- The active chilled beams can be identified by labels attached to both the active chilled beam and the plastic packaging.

Installation

The Halton Rex R6W active chilled beam is suitable for suspended ceiling mounting. The location of the supply air and water circuit connections is taken into account when selecting the orientation of the chilled beam.

The chilled beam can be attached directly to the ceiling surface (H1 = 195 mm) or suspended using threaded drop rods (8 mm). Depending on the length of the unit, the fixing points are located as shown in the drawings.

Install the main pipelines of the cooling and heating water circuits above the level of the chilled beam in order to enable venting of the pipework.

Installation with bracket

Commissioning

Cooling

The recommended cooling water mass flow rate is 0.02-0.10 kg/s, resulting in a temperature rise of 1-4 °C in the heat exchanger. To avoid condensation, the recommended inlet water temperature of the heat exchanger is 14-16 °C.

Heating

The recommended heating water mass flow rate is 0.01-0.04 kg/s, resulting in a temperature drop of 5-15 °C in the heat exchanger. The maximum temperature of the inlet water for the heat exchanger is 35 °C.

Balancing and control of water flow rates

The water mass flow rate, which can be controlled using an ON/OFF valve or a two—or three-way proportional valve, controls the chilled beam’s cooling and heating capacities.

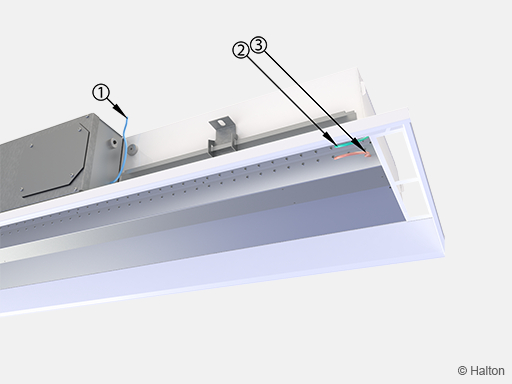

Adjustment of supply airflow rate

Connect a manometer to the measurement tap and measure the static pressure in the Halton Rex R6W chilled beam. Fig. 19 presents the measurement tab locations for OMD (Operation Mode Damper) and chambers 1 and 2.

Key:

| No. | Location | Colour |

|---|---|---|

| 1 | OMD | Blue |

| 2 | Chamber 1 | Green |

| 3 | Chamber 2 | Red |

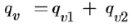

Total airflow rate (q v )

| qv | Total airflow rate, l/s or m3/h |

| qv1 | Chamber 1 nozzle jet airflow rate, l/s or m3/h |

| qv2 | Chamber 2 nozzle jet airflow rate, l/s or m3/h |

| leff | Length of the coil (beam length – 200 mm) |

| Δ pm | Chamber 1 measured pressure for qv1 or Chamber 2 measured pressure for qv2 |

| k [l/s] | k [m3/h] | |

|---|---|---|

| B | 1,06 | 3,82 |

| C | 1,35 | 4,86 |

The same k-factors will be used for all the operation modes.

Maintenance

| No. | Part | Description |

|---|---|---|

| 1 | Heat exchanger | – |

| 2 | Supply air connection | – |

| 3 | Operation mode damper (OMD) | Service hatch to access manual or motorized |

| 4 | Side plate | – |

| 5 | Front panel | – |

Open the front panel of the supply air chamber, the ductwork, and the heat exchanger. In beams longer than 2400 mm, it can be opened in two sections.

Clean the supply air chamber and finned coils of the heat exchanger with a vacuum cleaner, taking care not to damage the finned coils.

Clean the front panel and, if required, the side plates using a damp cloth.

Order code

R6W-M-S-L-P; SP-ED-TC-CR-CN-CO-ZT

| Main options | |

|---|---|

| M = Model | |

| F | Flexible |

| A | Autonomic |

| S = Nozzle size, 1st row | |

| B | Small |

| C | Medium |

| L = Beam length [mm] | 1200, +100,…,3600 (and 1720) |

| P = Nozzle size, 2 nd row | |

| B | Small |

| C | Medium |

| Other options and accessories | |

|---|---|

| SP = System package | |

| N | No |

| Y | Yes |

| ED = Duct connection | |

| R3 | Right (Ø160) |

| L3 | Left (Ø160) |

| TC = Cooling/Heating coil type | |

| C | Cooling |

| H | Cooling and heating |

| CR = Coil water pressure drop | |

| N | Normal |

| L | Low |

| CN = Control type | |

| MA | Manual |

| M1 | Motorised (0…10 VDC) |

| M2 | Motorised (Modbus RTU/BACnet MSTP) |

| CO = Colour | |

| SW | Signal white (RAL 9003) |

| X | Special colour (RAL xxxx) |

| ZT = Tailored product | |

| N | No |

| Y | Yes (ETO) |

| Sub products | |

|---|---|

| System package | Halton Workplace WRA |

| Room exhaust VAV damper | Halton Max MOC |

| Room exhaust VAV damper | Halton Max MUC |

| Order code example | |

|---|---|

| R6W-F-B-1800-B; SP=N, ED=R3, TC=C, CR=L, CN=M1, CO=SW, ZT=N |

Downloads

"*" indicates required fields