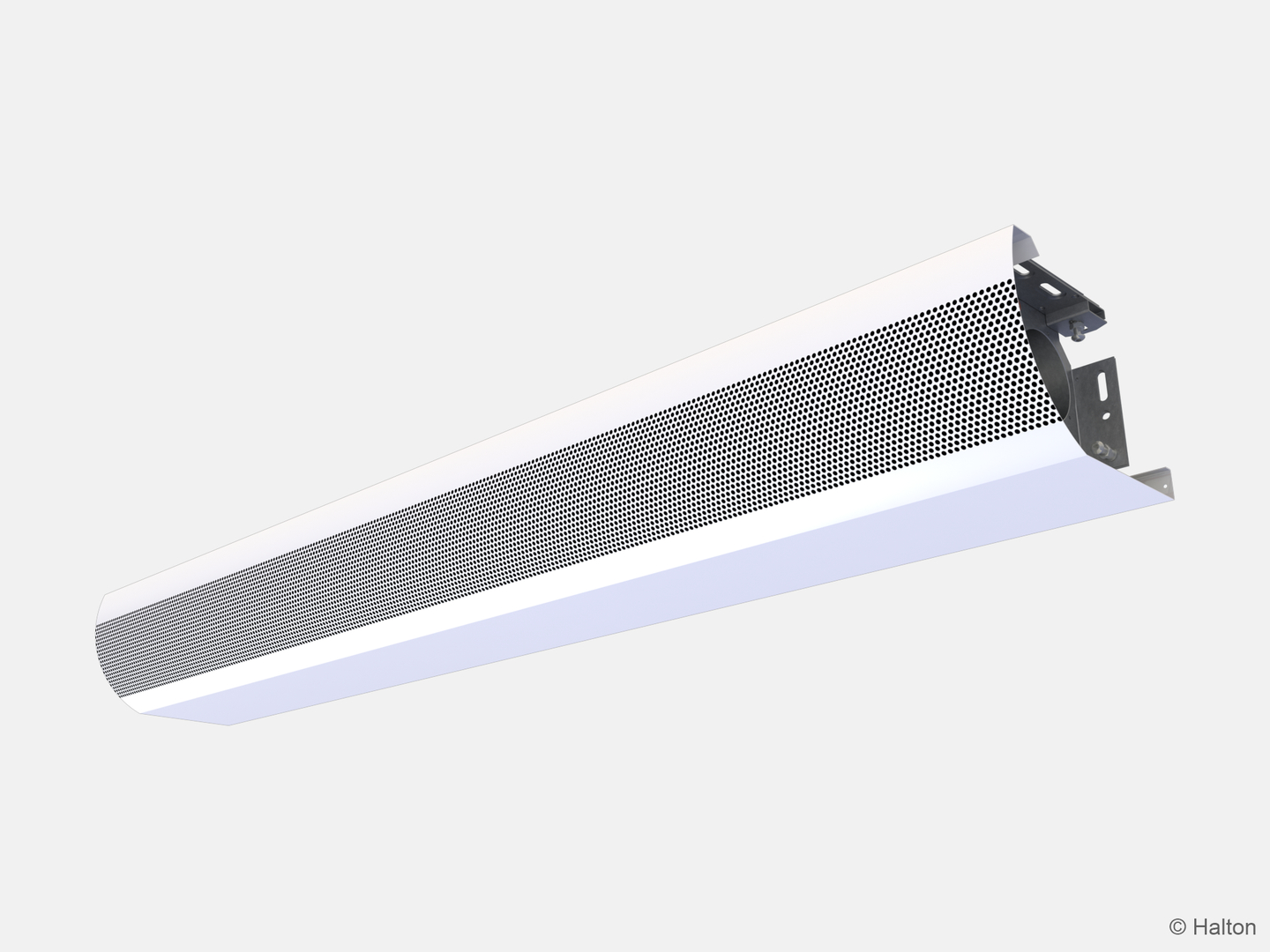

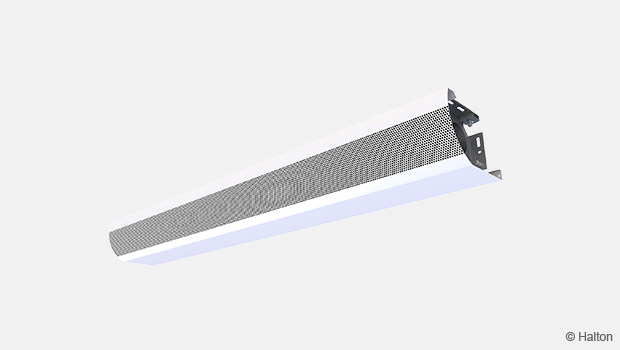

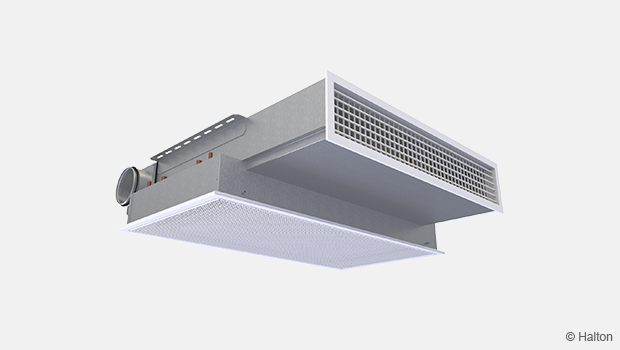

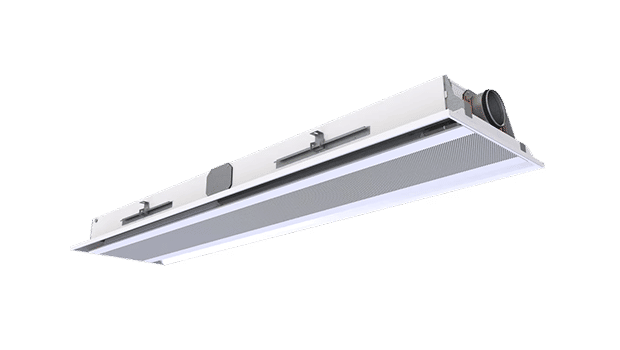

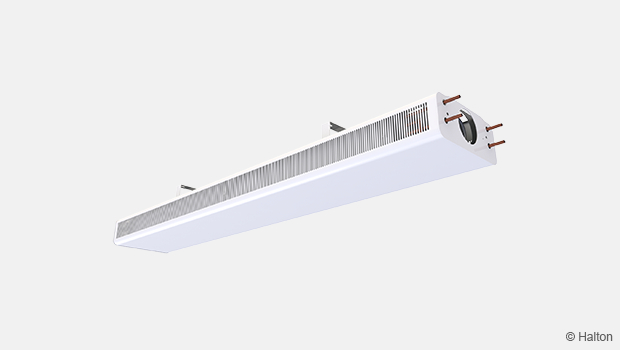

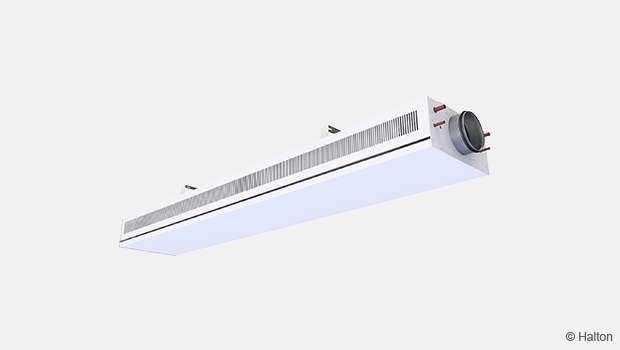

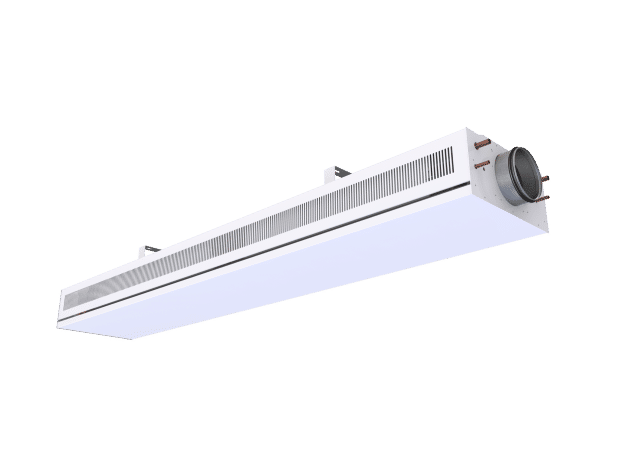

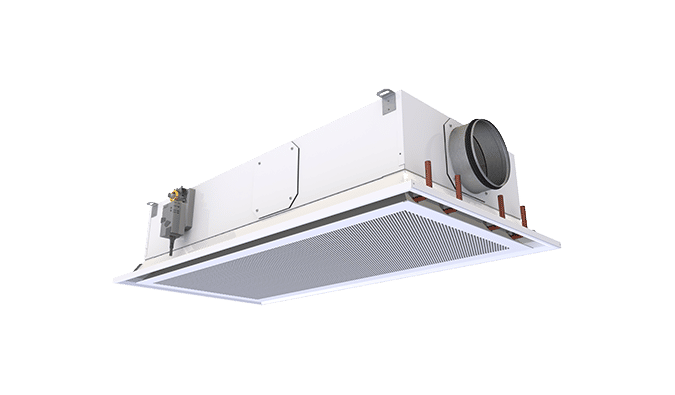

Product / Halton CaBeam/Exposed

Halton CaBeam – Chilled beam for exposed wall installation

Halton CaBeam is a cooling, heating, and ventilation solution specifically designed to provide the best indoor comfort for demanding marine applications such as cabins on cruise ships and passenger ferries or living quarters on offshore substations.

Specification

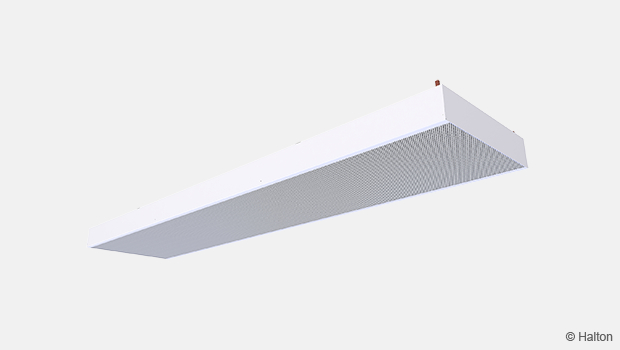

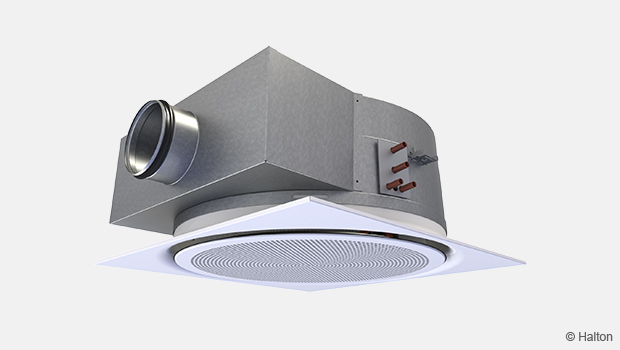

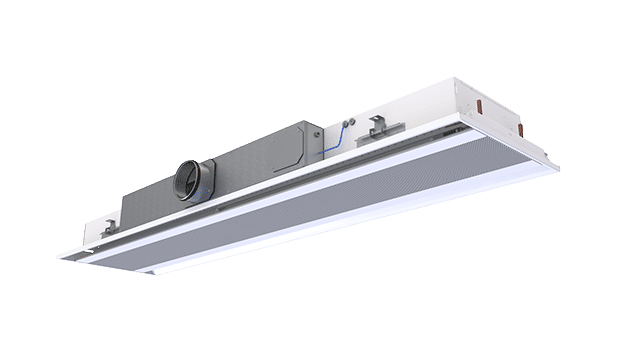

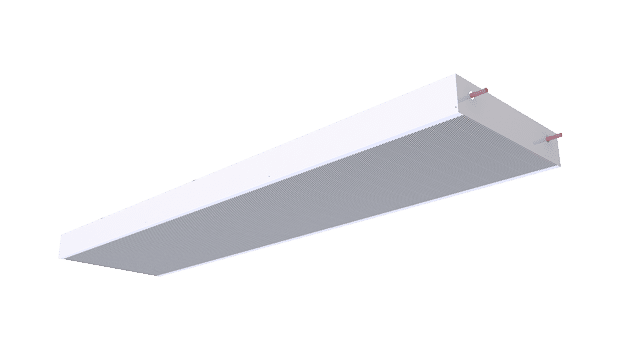

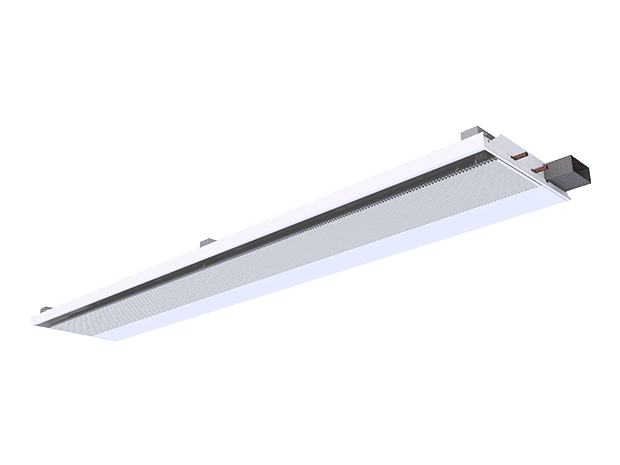

The Halton CaBeam units have been specifically designed for silent cabin comfort with sophisticated air treatment and control. The Halton CaBeam is available as an exposed, recessed or integrated installation.

The exposed CaBeam unit is an active chilled beam solution for demanding marine applications. The active chilled beam system employs fins to help heat and cool. The system is effective to the point where outdoor air can be mixed with the indoor air without any traditional air conditioning (such as heating, cooling, humidifying, or dehumidifying), allowing the building/ship to meet its “minimum outdoor air” air quality requirements.

The active chilled beam system requires much less energy to achieve the same heating and cooling effect as a traditional HVAC system.

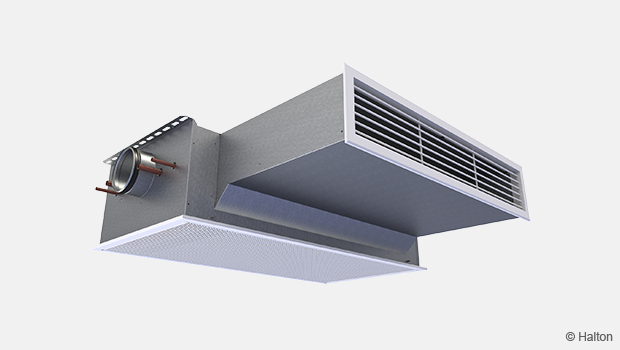

The beam acts as a radiator chilled by recirculated water. The warm air rises and is cooled by the chilled beam; once it is cooled, the air falls back to the floor, where the cycle starts over. The ventilation air is delivered to the beam by a central air-handling system via ductwork.

Overview

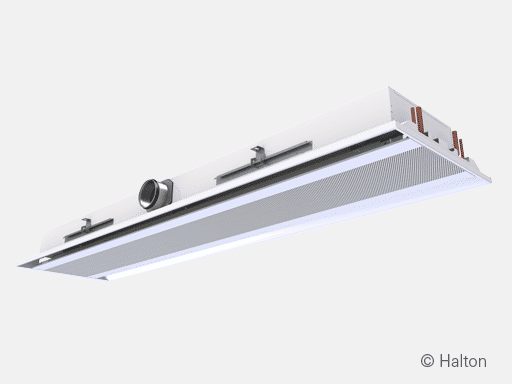

- The active chilled beam has an integral recirculation air path through the perforated front panel

- The front panel is openable from either side to allow general maintenance and cleaning

- The front panel is removable without any special tools

- The supply and return air grilles are openable and removable for maintenance

- The inlet duct connection is modifiable and can be located at the right, left, or middle of the supply-air plenum. When there is an integrated fan, there is no option for a connection in the middle

- The heat exchanger of the beam is oriented such that the water connections can be on either the right or left side of the beam

- All pipes are manufactured from copper, connection pipes with a wall thickness of 0.9–1.0 mm fulfilling the European Standard EN 1057:1996. The fins of the heat exchanger are manufactured from aluminium or copper as an option. The heat exchanger is factory pressure-tested. The maximum operating pressure of chilled/hot water pipework is 1.0 MPa

- The supply air ductwork connection is D125 mm

Tailoring

Important notice

The Halton CaBeam units can be tailored to customer demands according to the needed integration and requirements. Dimensions, capacities, and functionality details can be modified to project-specific. An advanced digital room temperature control completes the solution.

Materials

| PART | MATERIAL | FINISHING |

| Front panel | Pre-painted galvanised steel |

Polyester-epoxy-painted White RAL 9003 20% gloss* |

| Supply air plenum | Galvanised steel | |

| Brackets | Galvanised steel | |

| Coil pipes | Copper | |

| Coil fins | Aluminium | Copper as an option |

*) Special colours available

Features

The cooling philosophy of the beam is based on dry cooling.

Controls and functionality are designed to eliminate the risk of condensation and to provide the highest energy-efficiency possible. Cabin door or openable window can be equipped with switches to indicate an open/close position and connected to the Halton CaBeam automation.

The system can communicate with the operating crew for IEQ, as well as, energy-efficiency and is suitable for network communication (selected parameters).

Function

The supply air enters the plenum of the active chilled beam, from which it is diffused into the room through nozzles and the supply slot located on the top of the beam.

The supply air nozzle jets efficiently induce ambient room air, which is then directed horizontally along the ceiling surface. The secondary air is drawn through the perforation located at the bottom of the beam. The air is then cycled through the heat exchanger, where it is either cooled or heated before being diffused into the room.

The cooling capacities of the active chilled beam are controlled by regulating the water flow rate according to the control signal of the room temperature controller.

Installation

Easy installation can be ensured in a prefabricated cabin.

The manufacturing method and innovative, compact design allow units to be modified for any situation.

Design Criteria

- Room design temperature 22°C / 50% RH

- Fresh air rate 75 m3/h

Nozzle pressure 150-200 Pa - Sensible cooling power 600-1500 W (depending on coil and water parameters)

- Heating power 500-1200 W

- Noise level 25-30 dB(A), boost <35 dB(A)

- Supply and exhaust to design values, 20 dm3/s (75 m3/h)

- Chilled water flow to 0,100 dm3/s (360 dm3/h)

- Chilled water inlet temperature 15°C

- Chilled water outlet temperature 17°C

Note: Halton CaBeam systems are not exchangeable with FCU due to differences in the cooling circuit. Halton CaBeam systems take care of air distribution in the cabin as well.

Dimensions and Weight

| Coil length | 1500, 1600…4700 |

| L-5 | 1795, 1895…4995 |

| kg/m | 10 |

Location of the Pipe Connections

Adjustment

Cooling

The recommended cooling water mass flow rate is 0.03-0.10 kg/s, resulting in a temperature rise of 1-3°C in the heat exchanger. To avoid condensation, the recommended inlet water temperature of the heat exchanger is over 14°C.

Heating

The heating of the cabin is done by an electric heater in the primary air duct. Heating power in the normal cabin is typically 1-1,2 kW and capillary thermostat with manual reset is in close proximity of heater. Control of heater must be verified because in some cases there has been “leak” in control triac.

Heating with water (option)

The recommended heating water mass flow rate is 0.01-0.04 kg/s, resulting in a temperature drop of 5-15°C in the heat exchanger. The maximum recommended temperature of the inlet water for the heat exchanger is 35°C…45°C.

Balancing and control of water flow rates

Balance the water flow rates of the chilled beam with adjustment valves installed on the outlet side of the cooling and heating water loops. The cooling capacity and heating capacity of the chilled beam are controlled by regulating the water mass flow rate. The water mass flow rate can be controlled by using an ON/OFF valve or a two- or three-way proportional valve. Valves are not included in the delivery of the beams.

Adjustment of supply airflow rate

Connect a manometer in the measurement tap and measure the static pressure in the chilled beam. The airflow rate is calculated according to the formula below.

![]()

Ieff = length of the coil (m)

∆pm = measured static chamber pressure (Pa)

| NOZZLE | k (l/s) | k (m3/h) |

| A | 0,71 | 2,56 |

| B | 0,99 | 3,56 |

| C | 1,36 | 4,90 |

| D | 2,09 | 7,52 |

| E | 3,33 | 11,99 |

Condensation prevention

Air relative humidity and temperature will rise radically when the balcony door/window is opened. This could cause condensation on the surface of the beam coil. We are to prevent this undesired condensation by temperately heating the cooling water flow with 3,5 kW heater to raise beam coil surfaces above the dew point. This function is activated by the balcony door switch. Together with heating, the cooling valve is driven toward a closed position. Return water temperature is monitored by a sensor and when it reaches the desired level above the dew point the cooling valve is closed completely to prevent unnecessary heating of the cooling water circuit. When the balcony door remains open the cooling water circuit remains closed and coil surfaces remain above the dew point. The use of the condensation sensor and humidity sensor has been tested.

Relative humidity of air might also rise when the shower is on long periods and the toilet locker door is open.

Servicing

Code description for Exposed CaBeam

- Front panel

- Supply air connection

- Heat exchanger

- Female supply air connection

- Pipe connections

- Duct cover

Downloads

Request for Quotation

"*" indicates required fields