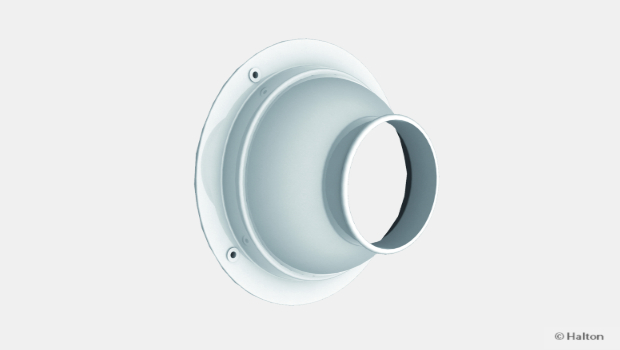

Product / DFA

Overview

Terminated as of 14th June 2024

-> no replacing product available

- Suitable for horisontal supply and exhaust

- Circular duct connection with rubber gasket

- Openable cone module enables cleaning of the diffuser and ductwork

- Lightweight aluminum material

Accessories

- Balancing plenum with measurement and adjustment functions

Dimensions

| NS | W | W1 | H | ØD |

| 125 | 295 | 150 | 63 | 124 |

| 160 | 370 | 225 | 63 | 159 |

| 250-445 | 445 | 300 | 63 | 249 |

| 250-520 | 520 | 375 | 63 | 249 |

| 315 | 520 | 375 | 63 | 314 |

| 400 | 595 | 450 | 100 | 399 |

Material

| Part | Material | Finishing | Note |

| Frame | Aluminium | Polyester-painted, White (RAL 9003/ 30% gloss) |

Epoxy-painting (100%) available |

| Front panel | Aluminium | Polyester-painted, White (RAL 9003/ 30% gloss) |

Epoxy-painting (100%) available |

| Perforated plate | Galvanised steel | 45 % perforation | – |

| Plenum / spigot | Galvanised steel | – | – |

Accessories

| Accessory | Code | Description |

| Balancing plenum | TRI/N | For balancing, equalizing the airflow (with airflow measurement and adjustment module) |

| Sound attenuation | IN | Polyester fibre ( Halton TRI) |

| Airflow measurement and adjustment module |

MSM | For supply installation |

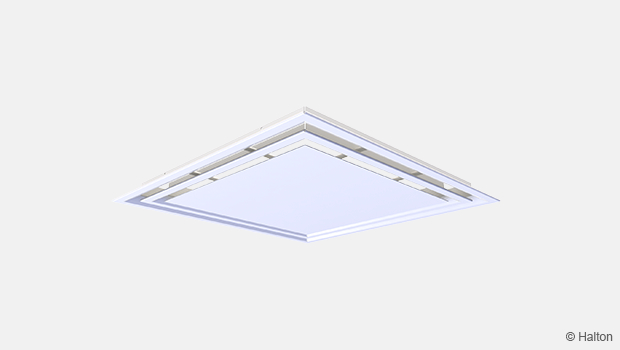

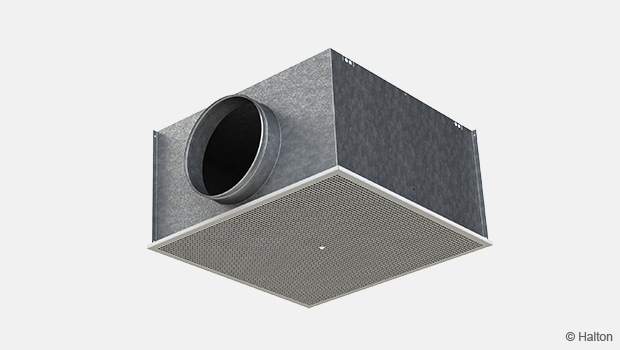

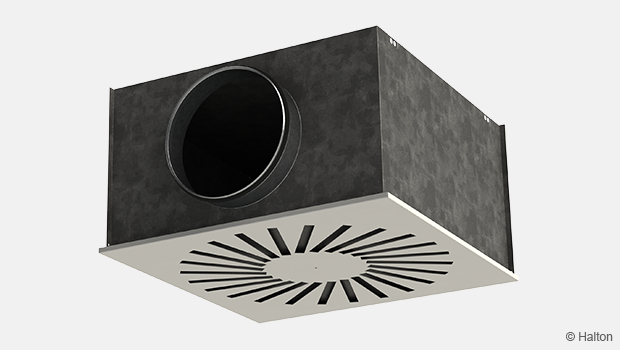

Fig.1. Halton DFA diffuser with Halton TRI plenum

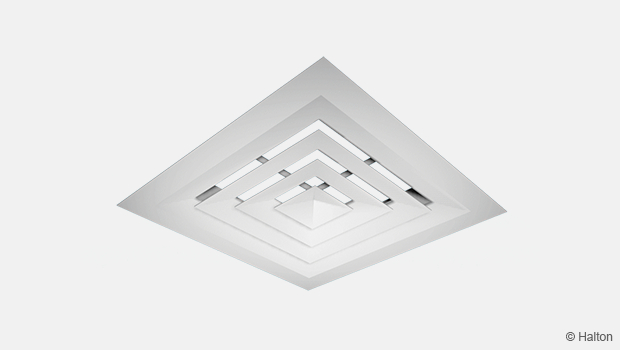

Function

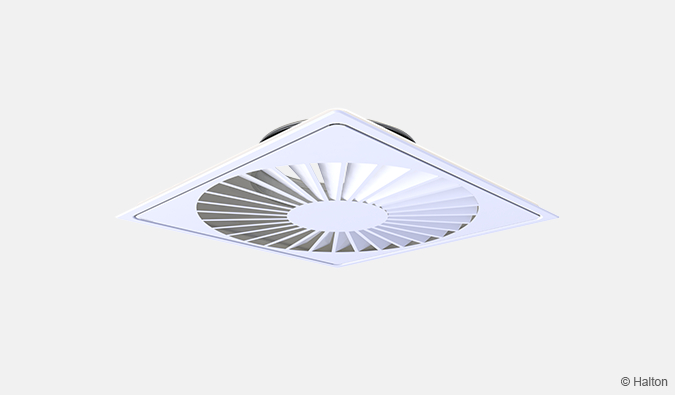

Air is supplied horizontally into the space through the slots of the conical front panel. Supply air mixes with room air in the vicinity of the diffuser.

The fixed cones of the diffuser are designed to ensure that the supply air flows along the ceiling. The Halton DFA diffuser can also be used as an exhaust unit.

Installation

Code description

1. Front panel

2. Frame

3. Perforated plate

The diffuser is connected either directly to the duct or using a Halton TRI balancing plenum.

Installation with Halton TRI plenum

| ØD | ØD1 | TRI | W2 | H1 |

| 125 | 100 | 100-125 | 235 | 272-322 |

| 160 | 125 | 125-160 | 310 | 302-352 |

| 250-445 | 160 | 160-250 | 385 | 342-392 |

| 250-520 | 200 | 200-250 | 460 | 392-442 |

| 315 | 250 | 250-315 | 460 | 456-506 |

| 400 | 250 | 250-400 | 535 | 456-506 |

The technical performance for the combination of supply air diffuser and Halton TRI plenum is presented separately for the two different installations.

Duct installation

When the Halton DFA diffuser is installed without a Halton TRI balancing plenum, it is recommended that the diffuser be connected to ductwork using a straight connection duct of minimum length 3xD upstream of the diffuser.

Adjustment

In order to enable airflow adjustment and measurement of airflow rate, it is recommended that the diffuser be connected to the Halton TRI balancing plenum equipped with the MSM module.

The supply flow rate is adjusted by using the measurement and adjustment module MSM.

Detach the front panel and pass the tubes and control spindle through the diffuser.

Measure the differential pressure using a manometer. The flow rate is calculated using the formula below.

Adjust the airflow rate by rotating the control spindle until the desired setting is achieved.

Lock the damper position with a screw.

Replace the tubes and spindle into the plenum and reattach the front panel.

The k factor for installations with different safety distances

(D= duct diameter)

| TRI | >6xD | min 3xD |

| 100 | 6.0 | 7.5 |

| 125 | 9.9 | 12.6 |

| 160 | 16.9 | 21.9 |

| 200 | 28.3 | 31.0 |

| 250 | 47.9 | 51.5 |

| 315 | 78.6 | – |

Servicing

Remove the front panel (central cones) by gently drawing out the central part.

Detach the perforated plate from the supply air section and sleeve.

Clean the parts by wiping them with a damp cloth.

Push the perforated plate back into place.

Push the front panel back into place so that the springs lock.

Option: with balancing plenum Halton TRI + MSM

Remove the measurement and adjustment module by gently pulling the shaft (not the control spindle).

Wipe the parts with a damp cloth, instead of immersing in water.

Reassemble the measurement and adjustment module by pushing in the shaft until the module meets the stopper.

Push the front panel back into place so that the clips lock.

Specification

The diffuser is made of extruded aluminium, anodised or polyester-painted with a white (RAL 9003) standard colour.

The bevel angles of the outer frame and central cone are welded so that the joints are almost invisible.

The diffuser has a galvanised steel transition to provide for circular duct connection. The spigot has a sealing gasket for airtight duct connection.

The diffuser is connected to the ductwork using a balancing plenum, which comprises polyester fibre with a washable surface as sound attenuation material.

The plenum is equipped with an airflow measurement and adjustment module.

The front panel of the diffuser is detachable in order to provide access to the measurement and adjustment module in the plenum.

Order Code

DFA-D-A; FI-CO-ZT

D = Connection size (mm)

125, 160, 250, 315, 400

A = Diffuser size (mm)

295, 370, 450, 520, 595

Other options and accessories

FI = Finishing

PN Painted

CO = Colour

SW Signal white (RAL 9003)

X Special colour

ZT = Tailored product

N No

Y Yes (ETO)

Sub products

TRI Plenum

Code example

DFA-125-295, FI=PN, CO=SW, ZT=N

Downloads

"*" indicates required fields