Product / CAR

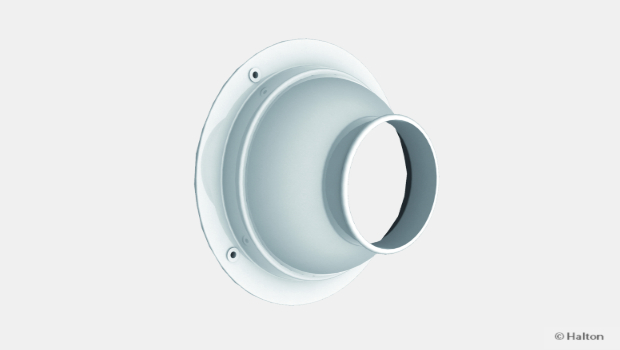

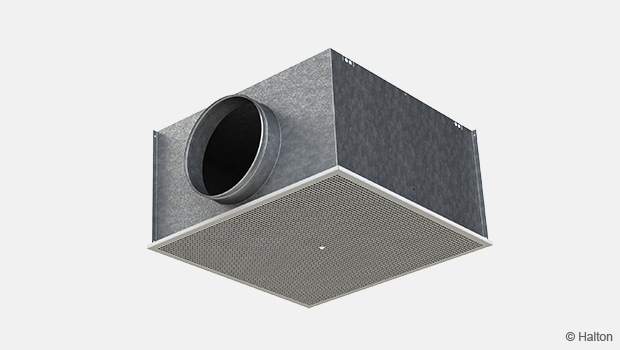

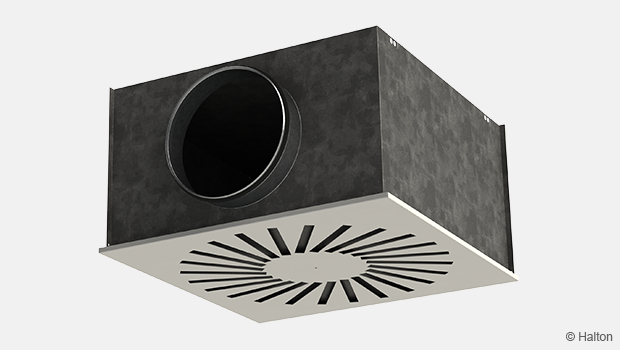

Halton CAR – Conical diffuser

Ideal for high spaces.

- Suitable for supply/exhaust and high airflow rates

- Cooling applications with supply/room air temperature difference as low as -16 °C

Overview

- Horisontal air supply

- Suitable for supply/exhaust and high airflow rates

- Cooling applications with supply/room air temperature difference as low as -16 °C

- Also suitable for heating

- Integrated or suspended ceiling installation

- Circular duct connection

- Openable cone module enables the cleaning of the diffuser and ductwork

Product models and accessories

- Adjusting and measuring with balancing plenum Halton Pop PDI

- Modular 600×600 mm suspended ceiling model

Quick selection

Values with adjustment modules (MSM) fully open.

Fig. 1. Quick selection with unit [l/s].

Fig. 2. Quick selection with unit [m3/h].

Dimensions

| CAR [mm] |

ØW [mm] |

H1 [mm] |

H2 [mm] |

ØD [mm] |

Weight [kg] |

| 160 | 343 | 66 | 83 | 159 | 1,4 |

| 200 | 457 | 76 | 84 | 199 | 2,5 |

| 250 | 571 | 83 | 99 | 249 | 3,9 |

| 315 | 686 | 87 | 118 | 314 | 5,4 |

| 355 | 857 | 96 | 148 | 354 | 8,3 |

| 400 | 857 | 96 | 148 | 399 | 8,3 |

| 450 | 1030 | 115 | 154 | 449 | 12,7 |

| 560 | 1200 | 118 | 213 | 558 | 17,2 |

Special dimensions are not available.

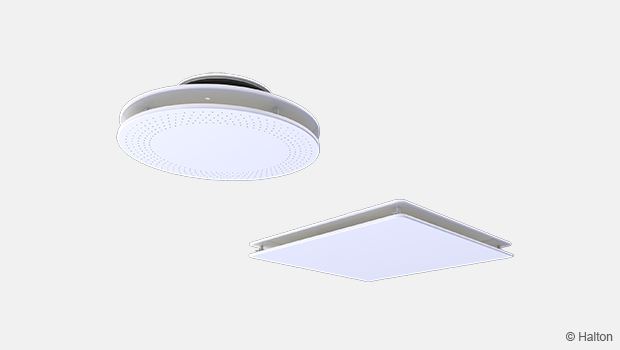

Halton CAR with Halton Pop PDI plenum

Fig. 3. Halton CAR with Halton Pop PDI plenum, internally positioned connection spigot.

Fig. 4. Halton CAR with Halton Pop PDI plenum, externally positioned connection spigot.

| CAR [mm] |

ØW [mm] |

PDI | ØD [mm] |

ØD1 [mm] |

L [mm] |

W1 [mm] |

H [mm] |

H1e [mm] |

H1i [mm] |

H2 [mm] |

L1 [mm] |

Weight [kg] |

| 160 | 343 | 125-160 | 124 | 162 | 308 | 282 | 172 | 85 | 25 | 83 | 168 | 4,1 |

| 343 | 160-160 | 159 | 162 | 458 | 358 | 239 | 85 | 25 | 83 | 280 | 6,4 | |

| 200 | 457 | 160-200 | 159 | 202 | 458 | 358 | 239 | 95 | 35 | 84 | 280 | 7,4 |

| 457 | 200-200 | 199 | 202 | 458 | 358 | 239 | 95 | 35 | 84 | 280 | 7,5 | |

| 250 | 571 | 200-250 | 199 | 252 | 458 | 358 | 239 | 102 | 42 | 99 | 280 | 8,8 |

| 571 | 250-250 | 249 | 252 | 520 | 480 | 359 | 102 | 42 | 99 | 280 | 12,1 | |

| 315 | 686 | 250-315 | 249 | 317 | 520 | 480 | 359 | 106 | 46 | 118 | 280 | 13,4 |

| 686 | 315-315 | 314 | 317 | 520 | 480 | 359 | 106 | 46 | 118 | 280 | 13,6 | |

| 400 | 857 | 315-400 | 314 | 402 | 520 | 480 | 359 | 115 | 55 | 148 | 280 | 16,3 |

Material

| Part | Material | Finishing |

| Diffuser | Steel | Epoxy-painted, white (RAL 9003/30%) |

| Plenum box | Galvanised steel | – |

Product models

| Product model | Code | Description |

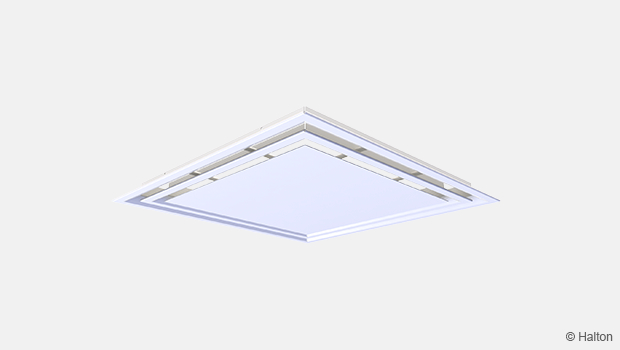

| Diffuser integrated in front panel, 600 x 600 mm |

CAR/B | Sizes 160, 200 and 250 are available as integrated in a steel panel for installation in a modular 600×600 mm suspended ceiling.The external dimensions of the front panel are 595 mm x 595 mm |

Function

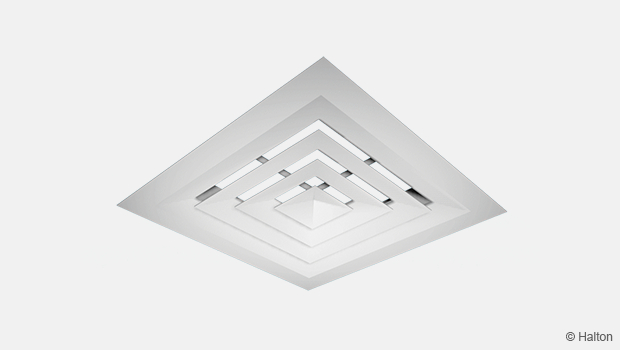

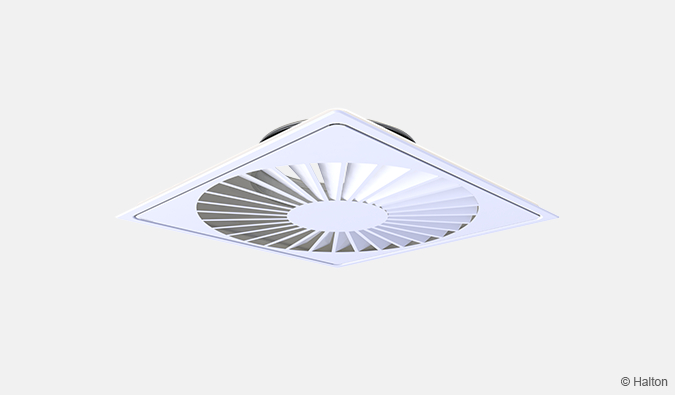

Supply air is divided into several jets through the cones.

The divergent sections of the diffuser create negative pressure under the diffuser so room air is induced into the supply air terminal. Room air and supply air mix.

This internal induction reduces temperature and the air velocity into the space.

The process is the same outside the diffuser between the supply and mixed room air, with external induction further reducing velocity and the temperature difference between supply and room air.

The diffuser can also be used as an exhaust unit.

Installation

Fig. 5. Halton CAR diffuser connected to a Halton Pop PDI plenum.

The diffuser is connected usually to balancing plenum Halton Pop PDI (see Fig. 5.) Alternatively, it can be connected direct to the duct by riveting or screwing. In that case, minimum safety distance to the next T-branch or curve is three times the duct diameter (3xD).

Commissioning

Fig. 6. Adjustment of airflow of diffuser and plenum combination.

The diffuser itself has no airflow adjustment. To adjust and measure the supply airflow rate, the diffuser shall be combined with Halton Pop PDI balancing plenum with measurement and adjustment module MSM. In case of exhaust air, use of adjustment module MEM is recommended. It is not possible to measure exhaust airflow rate with adjustment module MEM.

Pass the tubes and control spindle through the diffuser(Fig. 6). Measure the differential pressure with a manometer. The flow rate is calculated using the formula below:

![]()

where

qv Airflow rate [l/s] or [m3/h]

∆pm Measured pressure [Pa]

k k factor given as a function of mounting and diameter (see the table below)

Adjust the airflow rate by rotating the control spindle until the desired airflow rate (pressure difference) is achieved.

Set the tubes and spindle back into the plenum. Damper position can be locked with a knurled head screw of the adjuster.

| Duct connection (PDI) | k factor of MSM adjuster, opening > 0 [l/s] | |

| > 8D | Min. 3D | |

| 100 | 5.7 | 7.5 |

| 125 | 9.6 | 12.6 |

| 160 | 16.4 | 21.9 |

| 200 | 26.3 | 31.0 |

| 250 | 47.1 | 51.5 |

| 315 | 78.8 | – |

| Duct connection (PDI) | k factor of MSM adjuster, opening > 0 [m3/h] | |

| > 8D | Min. 3D | |

| 100 | 20.6 | 27.0 |

| 125 | 34.4 | 45.4 |

| 160 | 59.0 | 78.8 |

| 200 | 94.8 | 111.6 |

| 250 | 169.5 | 185.4 |

| 315 | 283.6 | – |

Service

Remove the conical central core by unscrewing it from the frame.

Clean the parts by wiping them with a damp cloth.

Put each screw back in place, and screw on until the conical central core fits in place.

Specification

The diffuser is made of several stamped cones, made of epoxy-painted steel with a white (RAL 9003/30%) standard colour.

The diffuser is suitable for installation on exposed ductwork or flush to the ceiling.

The diffuser is connected to the ductwork using a Halton Pop PDI balancing plenum, which utilises polyester fibre with a washable surface as sound attenuation material.

The diffuser is connected to the ductwork using a Halton Pop PDI plenum, which utilises mineral wool as sound attenuation material.

The plenum comprises an airflow measurement and adjustment unit.

The conical central core is removable.

The air discharge pattern is radial around the full perimeter of the air diffuser.

The cones form divergent sections, which creates under pressure inducing room air into the unit.

Order Code

CAR-D; WS-CO-ZT

| Main options | |

| D = Diameter of duct connection [mm] | 160, 200, 250, 315, 355, 400, 450, 560 |

| Other options and accessories | |

| WS = Width of suspended ceiling element | |

| NA | Not Assigned |

| CO = Colour | |

| SW | Signal white (RAL 9003) |

| X | Special colour (RAL xxxx) |

| ZT = Tailored product | |

| N | No |

| Y | Yes (ETO) |

Order code example

CAR-160; WS=NA, CO=SW, ZT=N

Downloads

"*" indicates required fields