Product / KCW

KCW – Water Wash ventilated ceiling (CE)

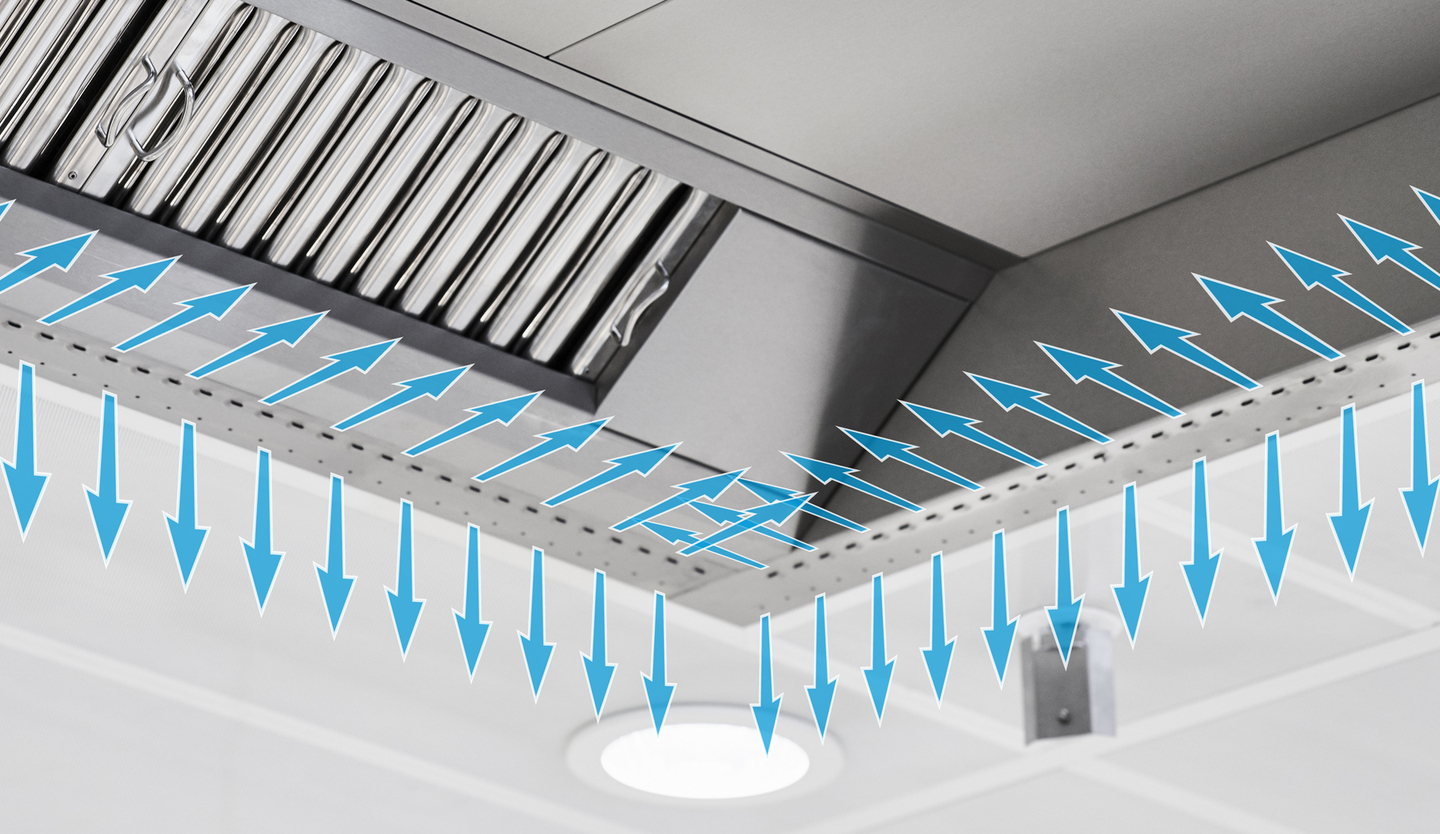

With Capture Jet™ technology and low velocity makeup air

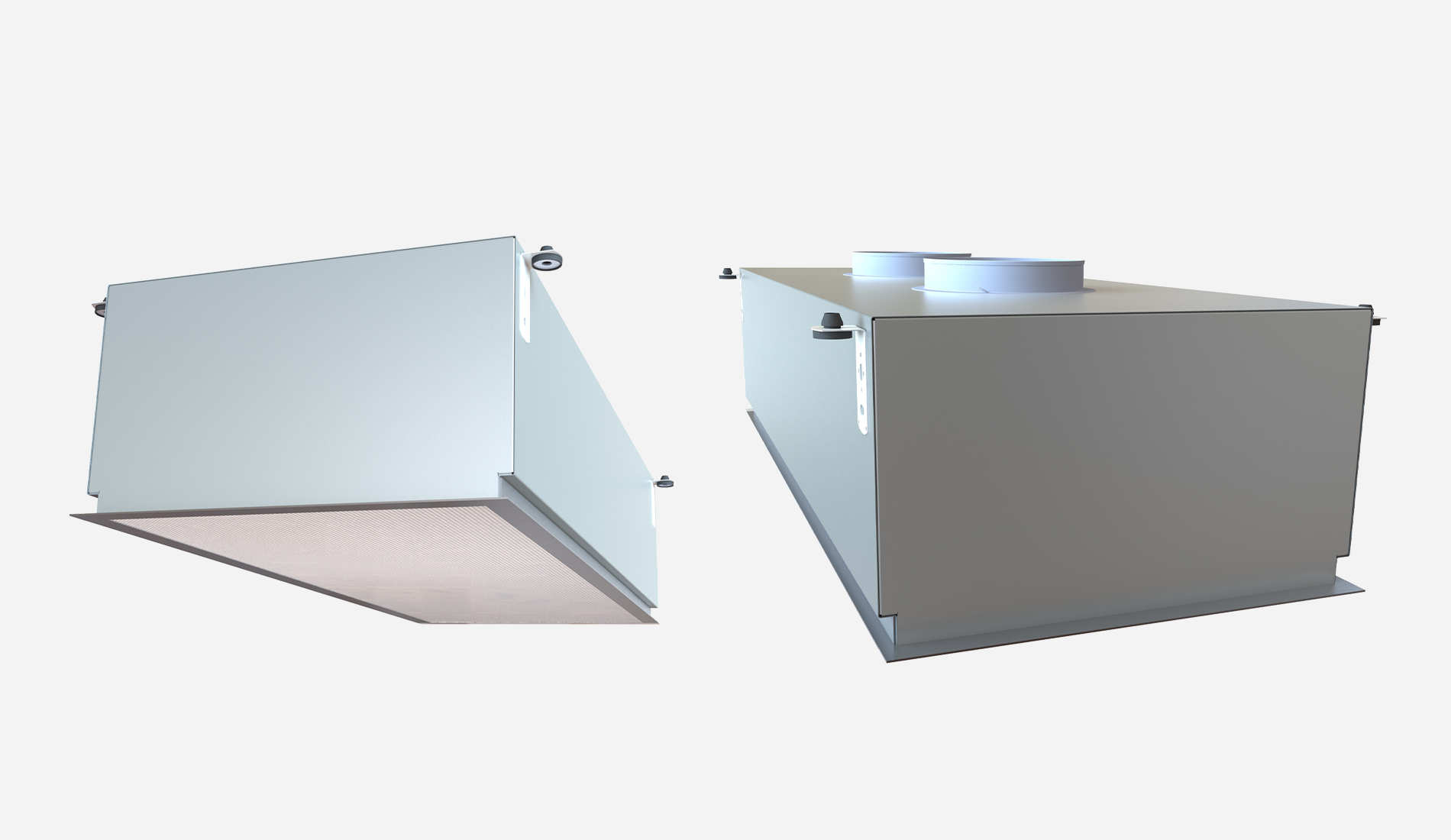

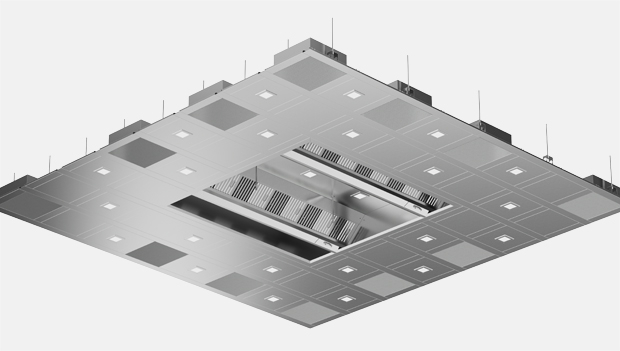

CE Marked (UKCA pending) – The KCW ventilated ceiling combines several functions: extraction, supply air, uniform lighting and rigid suspended ceilings above neutral areas. Equipped with Water Wash technology, it washes down the grease filters without the need for removal of the filters from the ceiling. This eliminates the need for a second set of filters.

The KCW ceiling is also equipped with the new generation of Capture Jet™ technology. It requires up to 15% less exhaust air volume than traditional ceilings to remove an equal heat load.

Overview

The KCW closed ventilated ceiling, with the Capture Jet™ technology, combines several functions: extraction, filter cleaning, air supply, lighting, and a suspended ceiling. it is suitable for open or show kitchens (hotels, hospitals, gastronomic restaurants, central kitchens, etc).

KCW ventilated ceilings are equipped with the Water Wash technology. It is designed to automatically carry out the regular cleaning of the filters, with no outside intervention necessary. It significantly reduces cleaning costs. Above all, users can devote themselves entirely to creating and preparing menus and food.

KCW ceilings free the kitchen from the space taken up by hoods. The entire kitchen then potentially benefits from the daylight, in addition to the integrated uniform and direct lighting. The visual comfort and the impression of space are incomparable. In the unlikely event of fire, it also provides an excellent protection, limiting its spread through the building.

Compared to hoods, heat and vapours are necessarily captured higher up. The latest generation of Capture Jet™ technology virtually constitutes an outer boundary for smoke to remove it efficiently.

Halton’s laminar flow units LFU provide a draught-free makeup air completing the action of the Capture Jets and improving staff comfort.

Considerable energy savings

- Up to 15% reduction in exhaust airflow rates due to Capture Jet™ technology.

- Possibility to extend the airflows reduction to up to 53% with M.A.R.V.E.L. energy savings technology.

Improved safety and maintenance savings

- FC aerosol separators, complying with EN 16282-6, 93% efficient on 10 microns particles or larger.

- Efficiently limits the build-up of grease deposits in the exhaust plenums and ductwork which constitute a serious hygiene and fire safety hazard. Reduces the cleaning costs.

- The Water Wash technology automatically cleans the filters with no staff intervention so that they can entirely devote to production. Further reduces the cleaning costs.

- The combination of the Water Wash exhaust plenum with FC filters has been tested according to DIN 18869-5 (ability to prevent flames passing through the filters).

Other features and benefits

- HACCP certified (Hazard Analysis Critical Control Point).

- Turnkey projects: Dimensioning and design of each project «made in Germany», including installation by Halton specialists.

- Requires the CCW control cabinet for the automatic washing cycles management.

- Equipped with Halton Connect IoT (Internet of Things) platform with advanced 24/7 distant monitoring capabilities.

- Highest value of ownership thanks to Halton Connect & Care smart services available as an option from kitchens commissioning.

- Halton Skyline LED culinary light provides the best visual comfort while contributing to further improve the safety and the energy savings.

- The Human Centric version of Halton Skyline directly contributes to chefs’ and their teams Wellbeing, especially when extended to all kitchen areas.

- Unrivalled working conditions due to optimal air quality and thermal comfort, combined with excellent visual and acoustic comfort.

- Exhaust airflow rates determined with a EN 16282-1 based calculation method taking into account the loads of the cooking appliances, the configuration of the extract system and its capture and containment efficiency.

- The entire system is fully comprehensive and includes extraction, low velocity make up air, lighting, integration of the additional services and the fully consistent suspended KCP ceiling for the neutral areas.

- Adaptable for later modifications to the layout of cooking appliances.

- Many possibilities of customization.

More about the main embedded technologies

Recommended combinations with other products or technologies

To further enhance the performance of your kitchen, whether talking about the energy savings, safety, Indoor Environment Quality (IEQ) or the kitchen’s impact on the environment, here are couple of combinations with other Halton products or technologies we recommend you.

Further increase the energy savings and improve the working conditions of the staff

Further increase the energy savings and improve the working conditions of the staff

Go for M.A.R.V.E.L. energy saving technology for kitchens ventilation

Get peace of mind by making no compromise on fire safety

Get peace of mind by making no compromise on fire safety

Go for the factory pre-installed FSS Fire Suppression System

Optimize the ductwork cleaning costs and further improve your safety

Optimize the ductwork cleaning costs and further improve your safety

Go for KGS grease deposition level monitoring system for ductwork

Reduce the ductwork cleaning costs, increase your safety and reduce the impact of your kitchen on the neighborhood

Reduce the ductwork cleaning costs, increase your safety and reduce the impact of your kitchen on the neighborhood

Go for the Capture Ray™ grease and odors neutralization technology

About Halton Connect & Care

Halton Connect is a state-of-the-art IoT (Internet of Things) platform whose core is an advanced cloud-based portal. It enables 24/7 remote monitoring of the solutions designed by Halton. It allows access to important and useful information along with powerful data analytics to the end users. It also provides crucial information to our engineers. In return, they can remotely and safely control all systems and their settings when required.

Halton Connect is a state-of-the-art IoT (Internet of Things) platform whose core is an advanced cloud-based portal. It enables 24/7 remote monitoring of the solutions designed by Halton. It allows access to important and useful information along with powerful data analytics to the end users. It also provides crucial information to our engineers. In return, they can remotely and safely control all systems and their settings when required.

This digital “two directions” technology opens the way to Premium Services that are vital to keep the performance of the systems and technologies at the initial design level and during the entire lifecycle. Even better! They enable continuous optimisation of your systems, resulting in even lower operating costs.

Downloads

-

Halton FS KCW Capture Jet Ceiling en

Data

English (en) -

Halton FS KCW Capture Jet Ceiling da

Data

Dansk (da) -

Halton FS KCW Capture Jet Ceiling pl

Data

Polski (pl) -

Halton FS KCW Capture Jet Ceiling zh

Data

简体中文 (zh) -

Halton FS KCW Capture Jet Ceiling fi

Data

Suomi (fi) -

Halton FS KCW Capture Jet Ceiling de

Data

Deutsch (de) -

Halton FS HCL Skyline Brochure en

Data

English (en) -

Halton FS EAC Certificate 01

Data

Русский (ru) -

Halton FS HACCP Halton Group Certificate

Data

English (en)

Request for Quotation

"*" indicates required fields