Product / KCV

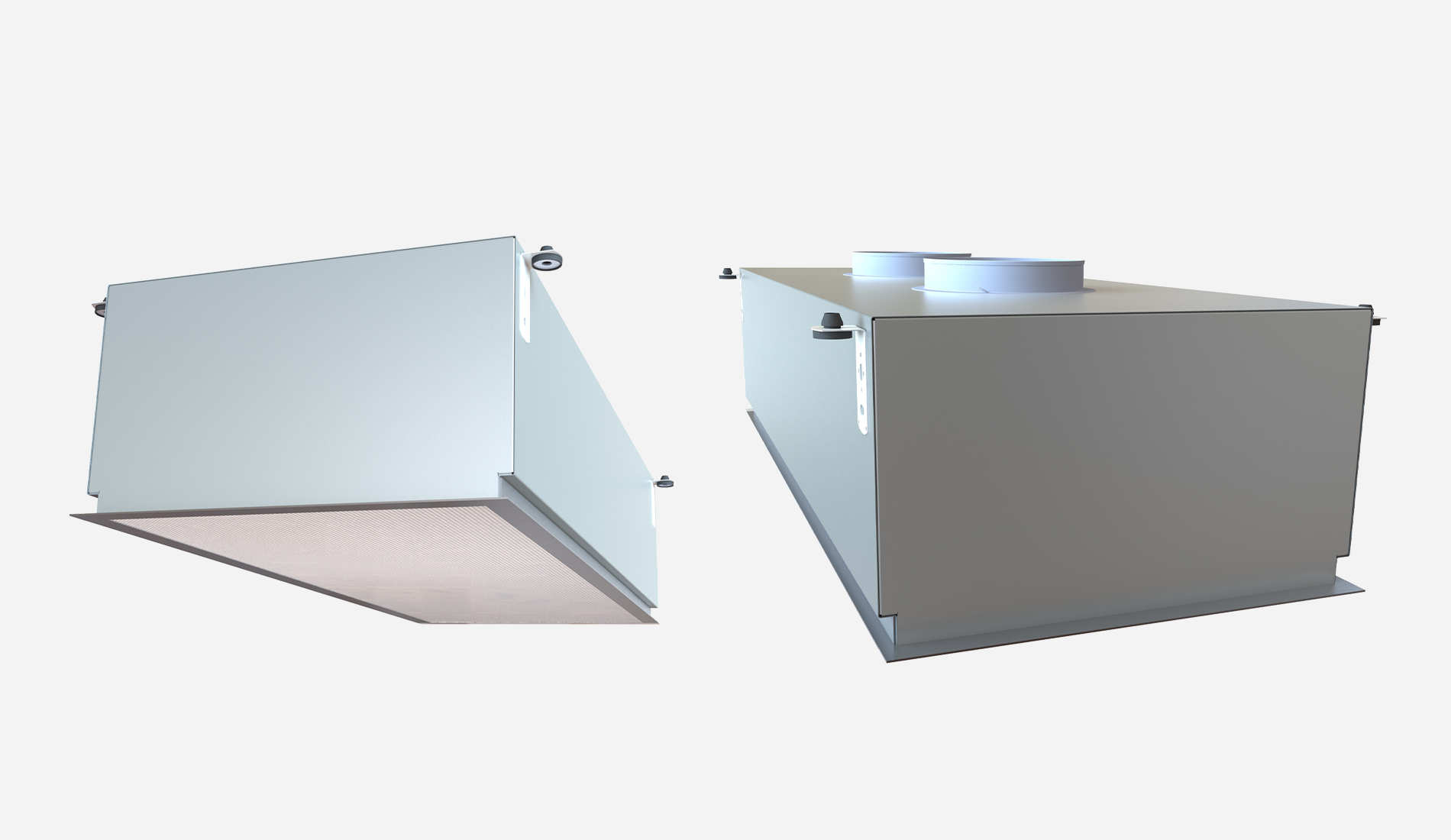

KCV – Ventilated ceiling for dishwashing areas (CE)

With low velocity makeup air and acoustic panels

CE Marked (UKCA pending) – Dishwashing areas are characterised by significant heat and humidity loads, not only from the washing process, but from the kitchenware that comes out and continues to cool down and dry where they are stored. Germs and bacteria on soiled guests’ plates and trays, as well as detergent, constitute additional pollutants. Sound generated by the equipment should also be taken into account.

On KCV ventilated ceilings, the Capture Jet™ technology becomes an option. The rest of the design is similar to KCJ ventilated ceilings.

Overview

The dishwashing areas are often considered as the last wheel of the coach. And yet, if some provisions are not taken, the working conditions inside can easily become a nightmare and hygiene of the kitchenware supposed to be clean can also be compromised.

Dishwashing areas are characterised by huge heat and humidity loads, not only coming from the washing equipment but also from the kitchenware that come out and continue to cool down and dry where they are stored. Germs and bacteria coming from guests’ plates and trays as well as detergent constitutes additional pollutants. Noise of the equipment should also be taken into account.

On KCV ventilated ceilings, the Capture Jet™ technology becomes an option. The rest of the design is similar to KCJ ventilated ceilings. Combined with KCP passive ceilings, KCV constitutes the best possible solution ensuring the full safety and good working conditions inside dishwashing areas.

Significant energy savings

- Capture Jet™ technology as an option for a better steam capture and containment.

- Drastic reduction of the exhaust airflow rates with the optional M.A.R.V.E.L. energy savings technology.

Improved safety and maintenance savings

- KSA cyclonic aerosol separators complying 95% efficient on 10 microns particles or larger.

- Limits the dust deposits which, together with heat sand steam, favors bacteria development inside the ductwork. Lowers the ductwork cleaning costs.

Other features and benefits

- Turnkey projects: Dimensioning and design of each project «made in Germany», including installation by Halton specialists.

- Halton Skyline LED culinary light provides the best visual comfort while contributing to further improve the safety and the energy savings.

- The Human Centric version of Halton Skyline directly contributes to chefs’ and their teams Wellbeing, especially when extended to all kitchen areas.

- The high lighting levels help to track the possible residual dirt at the outlet of the washing equipment and contribute to a better quality control.

- Can be equipped with double skin panels containing that a special acoustic foam protected by a PUR-plastic film on side of the perforated front. The noise level inside the kitchen can be reduced by up to 25 to 30%.

- Unrivalled working conditions due to optimal air quality and thermal comfort, combined with excellent visual and acoustic comfort.

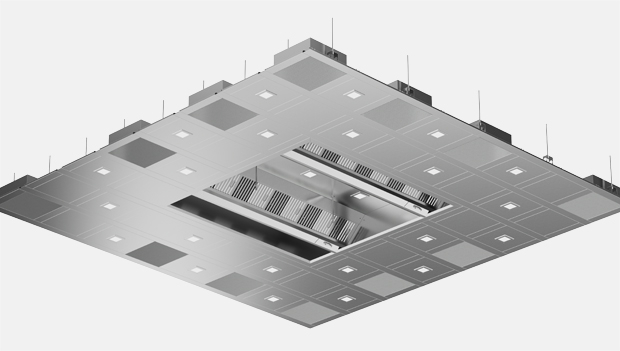

- The entire system is fully comprehensive and includes extraction, low velocity make up air, lighting, integration of the additional services and the fully consistent suspended KCP ceiling for the neutral areas.

- Cut-out options of the ceiling for the connection of the washing equipment’s outlets to the exhaust ductwork.

- Adaptable for later modifications to the layout of the dishwashing areas.

- Many possibilities of customization.

Why filtering the exhaust air of dishwashing areas?

The trash (food, napkins etc) on the trays and dirty dishes generate an impressive quantity of dust and particles. If not filtered, this dust quickly builds up deposits inside the ductwork. They are similar to a “fluff” that is ideal for bacteria development thanks to the steam and heat released by the equipment.

Having a mechanical filtration in dishwashing areas prevents the build-up of these bacteria traps. The dust deposition on the filters after only one day’s operation speaks for itself.

More about the main embedded technologies

Recommended combinations with other products or technologies

To further enhance the performance of your kitchen, whether talking about the energy savings, safety, Indoor Environment Quality (IEQ) or the kitchen’s impact on the environment, here are couple of combinations with other Halton products or technologies we recommend you.

Further increase the energy savings and improve the working conditions of the staff

Further increase the energy savings and improve the working conditions of the staff

Go for M.A.R.V.E.L. energy saving technology for kitchens ventilation

About Halton Skyline

Halton Skyline is the first LED based lighting technology specifically developed for commercial kitchens. Everyone agrees the light it provides is simply the closest possible to natural light. Halton Skyline is embedded in Halton’s hoods, ventilated ceilings and hard false ceilings. Also available as standalone light fittings, its use can be extended to all areas of kitchens.

Halton Skyline is the first LED based lighting technology specifically developed for commercial kitchens. Everyone agrees the light it provides is simply the closest possible to natural light. Halton Skyline is embedded in Halton’s hoods, ventilated ceilings and hard false ceilings. Also available as standalone light fittings, its use can be extended to all areas of kitchens.

Halton Skyline represents a unique set of real benefits for the chefs, their staff and even their guests when it comes to display kitchens.

- A Culinary Light that remarkably respects the food colour and plasticity from raw ingredients to plated presentation

- A Culinary Light that also improves the working conditions while playing an active role in the kitchen safety

- A Human Centric light that follows your biorhythm to further improve the working conditions and staff Wellbeing

- A state-of-the-art lighting technology that, at its core, saves significantly on energy and maintenance

Downloads

"*" indicates required fields