Product / KWF

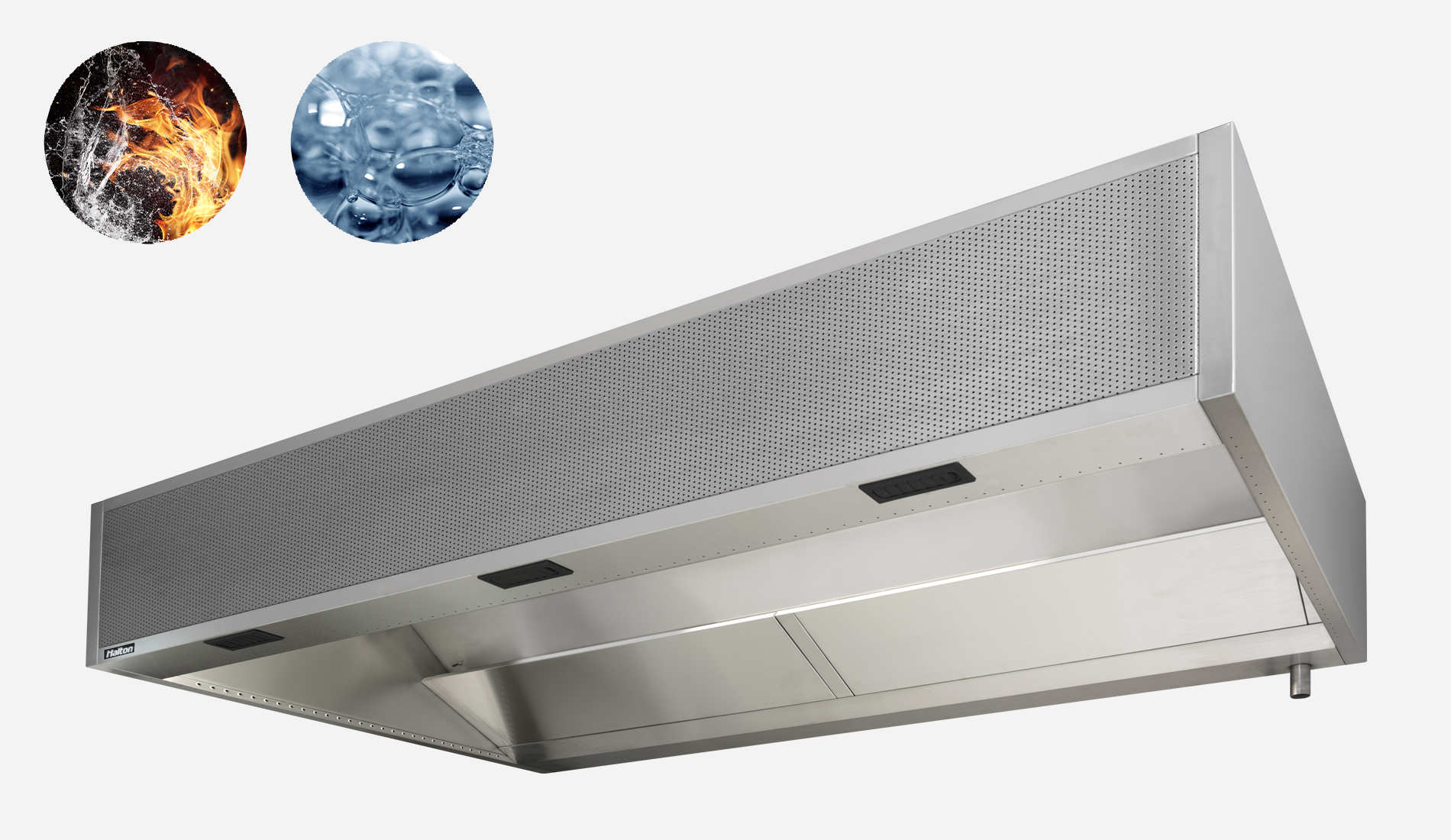

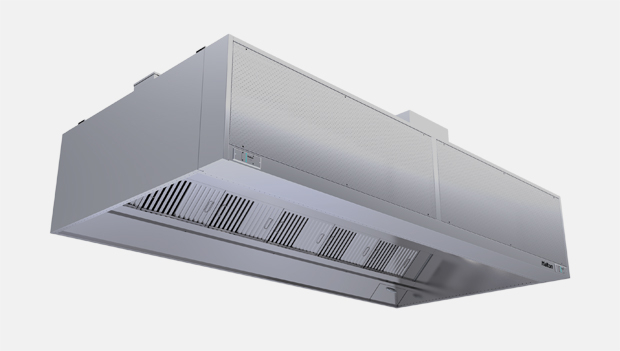

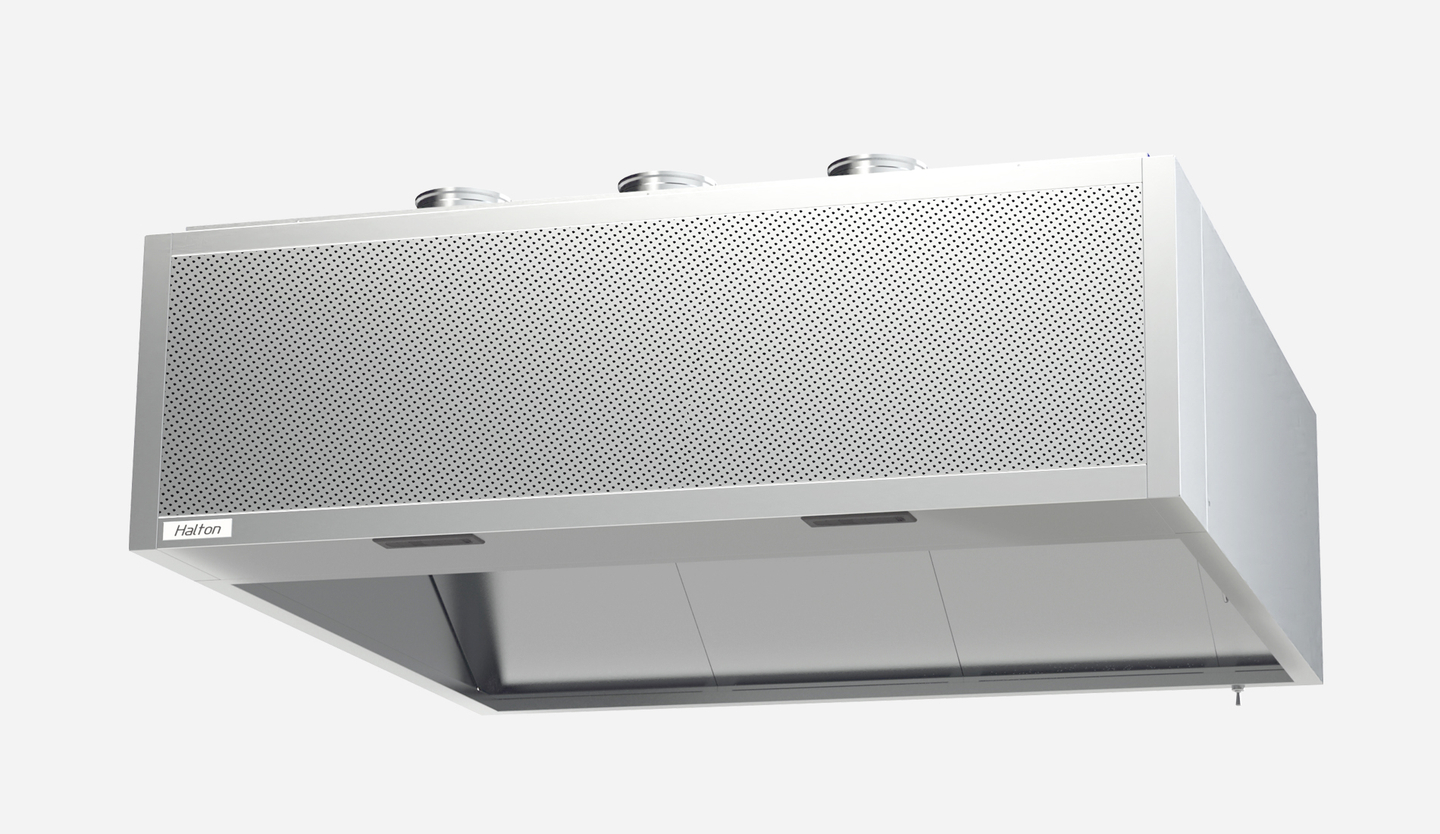

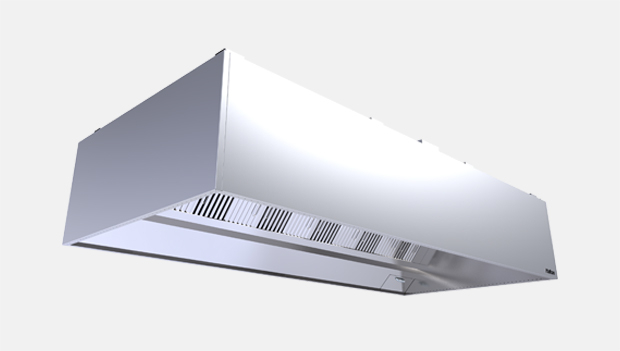

KWF Water Wash hood with Capture Jet™ (CE)

Main features

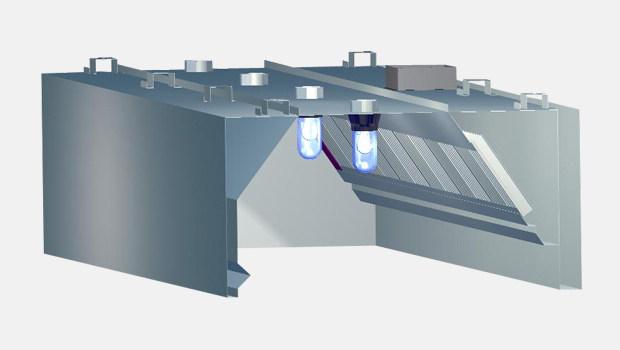

◦ Capture Jet™ technology ◦ KSA cyclonic aerosol separators ◦ Water Wash technology ◦ Halton Skyline LED Lighting ◦ Integrated low velocity makeup air ◦ CE marked ◦ UKCA pending

Main benefits

- Drastic energy savings thanks to reduced airflows

- Savings on exhaust plenum and ductwork cleaning thanks to lower formation of grease deposits

- Additional savings on filters cleaning

- Better thermal comfort thanks to draft risk’s reduction

- Improved visual comfort and color render for the food

Overview

Halton Capture Jet™ hoods and ventilated ceilings are all suitable for LEED (1), BREEAM (2), DGNB (3), RE2020 (4) etc. projects, particularly when combined with M.A.R.V.E.L. airflow and energy optimization technology. They can be used in all closed, opened, or show kitchens , and in general, all food-producing environments..

In addition to the Capture Jets, KWF hoods are also equipped with the Water Wash technology. This technology is more typically used for commercial kitchens with a large operating hours range that leaves little time for filters cleaning.

Description

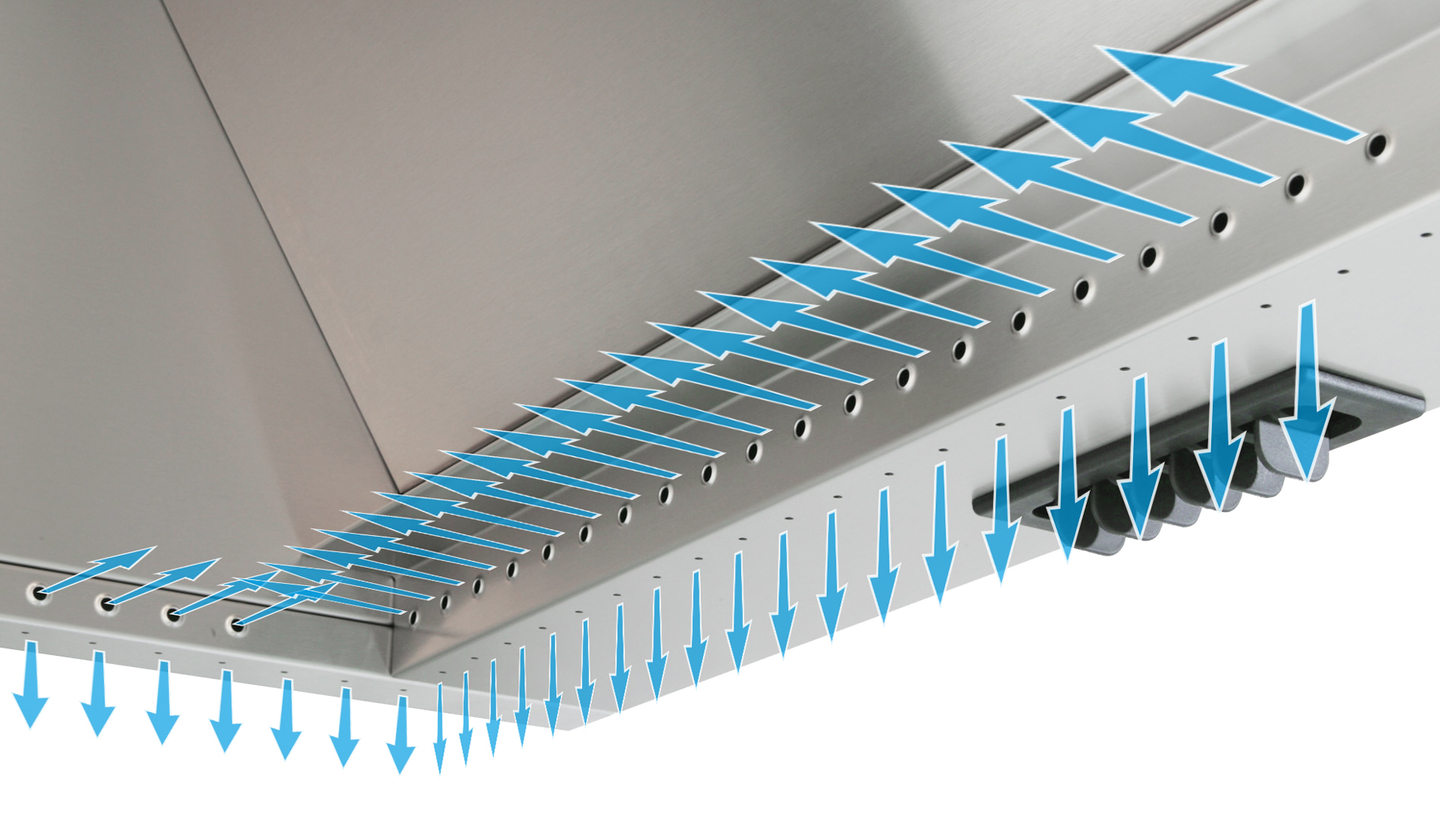

The Capture Jet™ technology enables significant reductions in airflow rates leading to savings on construction costs, mainly due to the reduced size of ducts and HVAC equipment. It typically pays for itself upon the startup of the kitchen or within few months. The energy savings it generates then directly contribute to an increase in profitability, while the staff benefits from improved working conditions.

The Water Wash technology is designed to automatically carry out the regular filters cleaning, with no outside intervention necessary. It saves a lot on filters cleaning cost. The productivity, the hygiene and the fire safety are also improved.

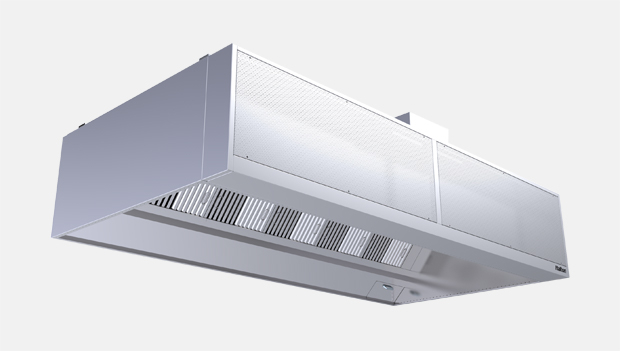

KWF hoods are lastly equipped with a low-velocity makeup air built into the front face.

Considerable energy savings

- The Capture Jet™ technology allows for up to a 40% reduction in exhaust airflow rates.

- The combination with M.A.R.V.E.L. airflow and energy optimization technology allows for reducing the exhaust volumes by up to an additional 44% on top of that of the Capture Jet™ resulting in up to a 64% total reduction. Energy savings are then massive.

- It generates important energy savings on cooling/heating the makeup air (less air out, less air in!).

- The reduced draft risk and noise levels improve the working conditions for the staff.

Improved safety and maintenance savings

- KSA cyclonic aerosol separators constructed of stainless steel in compliance with EN 16282-6. They are up to 95% efficient on 10 microns particles or larger. Also certified UL 1046, NSF, and LPS 1263.

- KSA cyclonic aerosol separators efficiently slow down the build-up of grease deposits in the exhaust plenums and ductwork that could otherwise constitute a serious hygiene and fire safety hazard. It also results in savings on the ductwork cleaning cost.

- The Water Wash technology limits the need for filter removal to infrequent deep cleaning operations.

- By construction, the Water Wash technology improves the protection against the propagation of a cooking fire to the ductwork, especially when combined with Halton FireWatch technology.

Other features and benefits

- Construction compliant with NF EN 16282-2 (5).

- HACCP (6) International certified.

- Integrated fan for the Capture Jet™ technology. No additional duct is required.

- Capture Jets are automatically switched off when the hood is not used or operates at a minimum airflow.

- Requires a control cabinet from CCW range for the automatic washing cycles management.

- Advanced 24/7 distant monitoring capabilities thanks to Halton Connect IoT (Internet of Things) platform.

- Highest value of ownership thanks to Halton Connect & Care smart services available as an option from kitchens commissioning.

- Halton Skyline (HCL) LED culinary light provides the best visual comfort while contributing to further improve safety and energy savings.

- When extended to the whole kitchen and surrounding areas, the Human Centric version of Halton Skyline (HCL) directly contributes to chefs’ and their teams wellbeing.

- Better capture efficiency and comfort for the staff thanks to a low-velocity diffuser built into the front.

- Capture and containment efficiency tested in accordance with the ASTM 1704 standard.

(1) LEED – Leadership in Energy and Environmental Design (2) BREEAM – Building Research Establishment Environmental Assessment Method (3) DGNB – German Sustainable Building Council (4) RE2020 – French Environmental Regulation 2020 (5) NF EN 16282-2 Equipment for commercial kitchens – Components for ventilation in commercial kitchens – Part 2 : kitchen ventilation hoods – Design and safety requirements (6) HACCP – Hazard Analysis Critical Control Point

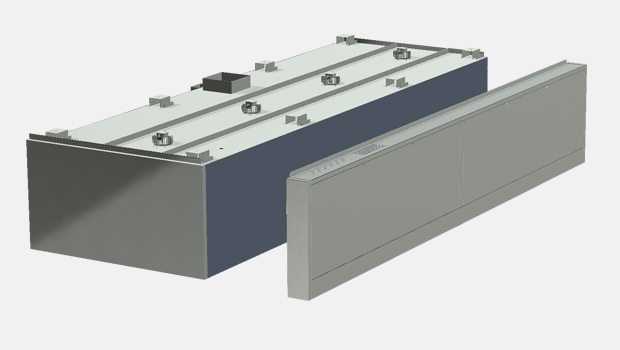

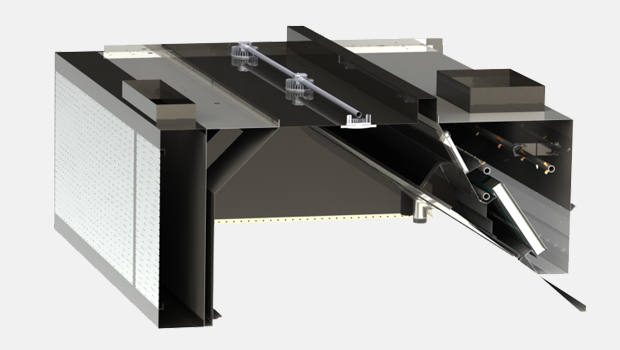

Construction

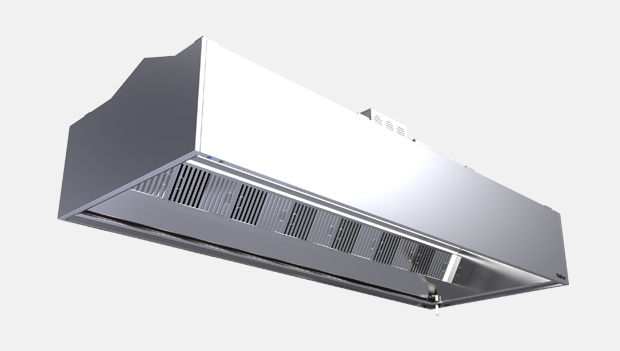

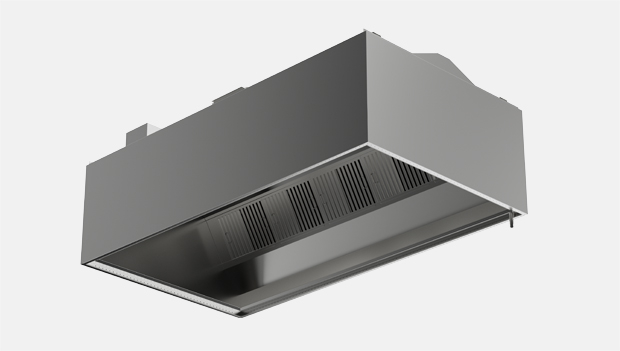

- Visible outer envelope in stainless steel AISI 304 (1,0 mm).

- Exhaust plenum fully constructed of stainless steel AISI 304 (1,2 mm).

- KSA aerosol separators.

- Removable deflectors.

- Water drain threaded pipe (DN50).

- Stainless steel manifold equipped with plastic spraying nozzles, removable without tool, supplied with hot water (filters cleaning).

- [Option] Additional stainless steel manifold equipped with plastic spraying nozzles, removable without tool, supplied with hot water (exhaust plenum cleaning).

- Solenoid valve(s) controlled (either directly or via the controllers’ network) by one of the control cabinets in the CCW range.

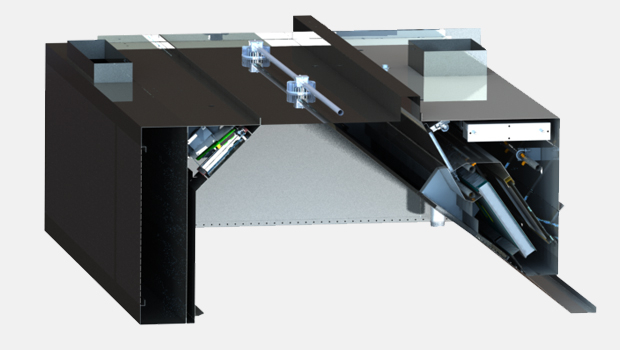

- Exhaust connection(s) and sliding damper(s).

- When the kitchen is equipped with M.A.R.V.E.L. airflow and energy optimization technology (MRV), the sliding damper is replaced by ABD automated balancing slim damper.

- T.A.B.™ (Testing And Balancing) pressure port(s) for quick airflow calculation during ductwork balancing operations.

- Front Capture Jet™ nozzles.

- Double skin sides.

- Side Capture Jet™ nozzles.

- Integrated Capture Jet™ fan.

- Halton Thermal Imaging sensor for the optional FireWatch or M.A.R.V.E.L. technologies.

- Halton Skyline LED culinary LED light fitting integrated on a flush-mounted access hatch. Systems’ control module installed on top of the light fitting.

- As an option, Halton Skyline LED spots integrated on a full width and flush-mounted light beam(s).

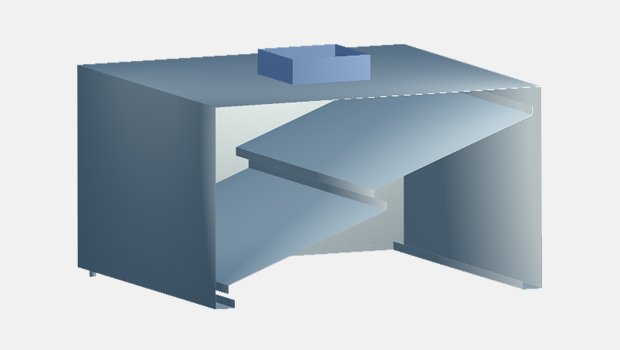

- Makeup air plenum.

- Perforated front face with honeycomb structure for a low velocity makeup air.

- Personal supply air nozzles.

- Supply air connection and adjustment damper (type MSM).

M.A.R.V.E.L. ready option: To allow for later installation of M.A.R.V.E.L. airflow and energy optimization, each hood can be equipped only with its ABD slim automated balancing damper, which is typically very difficult to install afterward.

Dimensions

Notes:

- Above 3100 mm, hoods are an assembly of separate sections to make transportation and site handling easier.

- Number of connections to be determined based on the sections length and on the calculation of the airflow rates (depending on the cooking appliances).

- Rectangular connections on request.

Admissible and calculated airflows

Admissible airflows

(1) QE Min/KSA = 505 m3/h | QE Max/KSA = 786 m3/h – ∆PT.A.B. Min = 59 Pa | ∆PT.A.B. Max = 144 Pa

(2) Side Jets with W=1300 mm

Calculated airflows

The calculated exhaust airflow rates are determined with a EN 16282-1 based calculation method. It relies on the evaluation of the convective flows’ volume (air mixed with heat, steam, grease, smoke and other pollutants) generated by the cooking appliances, depending on their type, on the energy they use and their installation conditions (central, on a wall, in an angle).

The air volume required to remove the convective loads is then calculated depending on:

- The hood or ventilated ceiling installation height;

- The makeup-air strategy (mixing or displacement);

- The hood or ventilated ceiling capture efficiency according to ASTM 1704-12 standard.

KWF hood reduces the exhaust airflow rates(1) by up to 40% compared to traditional hoods.

(1) This scale is indicative and based on wall mounted hoods, opened on 3 sides, equipped with a same cooking bloc, whatever it is. The variation in exhaust airflow reduction for a given hood type is due to the makeup-air type (mixing or displacement). Other parameters do impact the final airflow rates. Our sales teams are at your disposal to provide you with a calculation note, depending on your kitchen configuration.

Downloads

-

Halton FS KWF WWash Capture Jet hoods zh

Data

简体中文 (zh) -

Halton FS KWF WWash Capture Jet hoods fi

Data

Suomi (fi) -

Halton FS KWF WWash Capture Jet hoods de

Data

Deutsch (de) -

Halton FS KWF WWash Capture Jet hoods pl

Data

Polski (pl) -

Halton FS KWF WWash Capture Jet hoods da

Data

Dansk (da) -

Halton FS KWF WWash Capture Jet hoods en

Data

English (en) -

Halton FS HCL Skyline Brochure en

Data

English (en) -

Halton FS EAC Certificate 01

Data

Русский (ru) -

Halton FS HACCP Halton Group Certificate

Data

English (en)

Request for Quotation

"*" indicates required fields