Product / TLD

Overview

- Horizontal plane jet air supply

- Directional nozzles with two-slot air path which deflect the air streams effectively

- Installation of the diffuser on the wall in the vicinity of the ceiling

- Airflow rate measurement and adjustment functions

- Circular duct connection with gasket on the back or on the side of the plenum

- Cleaning of the terminal unit and supply ductwork enabled by the detachable diffuser section

Product models and accessories

- Plenums with duct connection on the back or side

- Cover sleeve for exposed installations

Quick selection

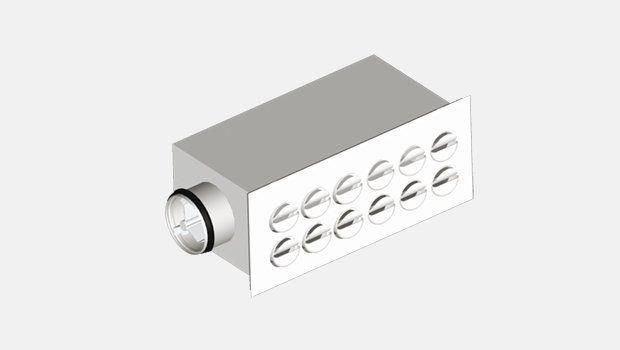

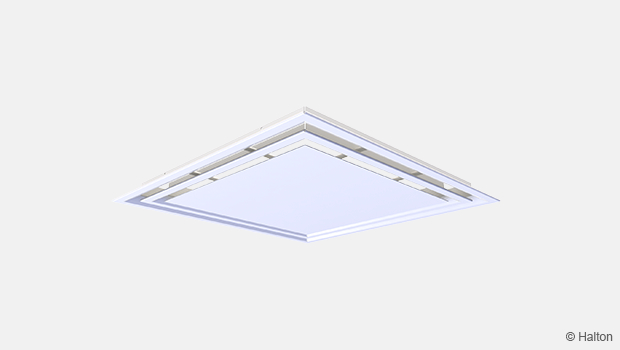

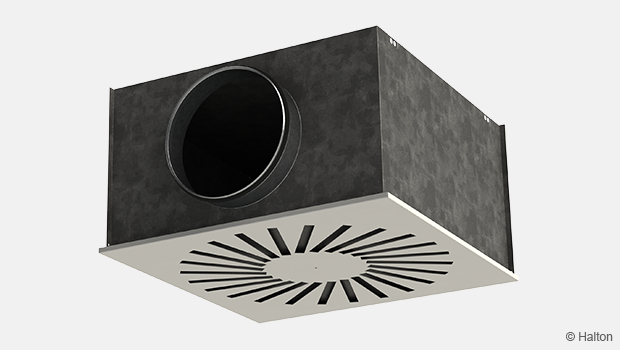

Fig.1. Halton TLD with back connection, supply (with MSM-module)

Fig.1. Halton TLD with back connection, supply (with MSM-module)

Dimensions and weight

Halton TLD/B (back connection)

| NS | W | W1 | H | H1 | K | ØD |

| 100 | 441 | 403 | 191 | 153 | 204 | 99 |

| 125 | 441 | 403 | 241 | 203 | 204 | 124 |

| 160 | 541 | 503 | 241 | 203 | 241 | 159 |

| 200 | 741 | 703 | 291 | 253 | 280 | 199 |

| 250 | 793 | 751 | 341 | 304 | 299 | 249 |

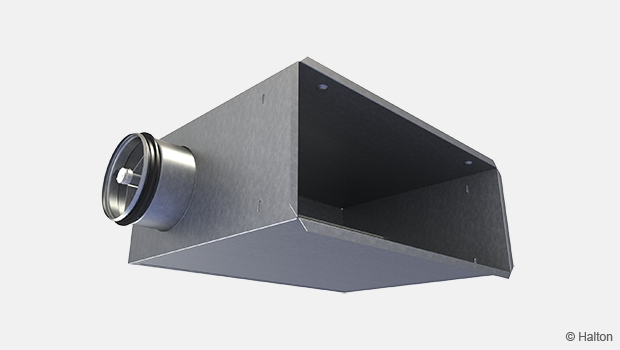

Halton TLD/E (side connection)

| NS | W | W1 | H | H1 | K | K1 | ØD |

| 100 | 441 | 403 | 191 | 153 | 301 | 211 | 99 |

| 125 | 441 | 403 | 241 | 203 | 301 | 198 | 124 |

| 160 | 541 | 503 | 241 | 203 | 408 | 286 | 159 |

| 200 | 741 | 703 | 291 | 253 | 408 | 265 | 199 |

NOTE! Size 250 is not available for side connection.

Weight (kg)

| NS | TLD/B (back connection) |

TLD/E (side connection) |

TLD/A (diffuser section) |

| 100 | 1.9 | 2,8 | 1,7 |

| 125 | 2.2 | 3,2 | 2,1 |

| 160 | 2.9 | 4,5 | 2,1 |

| 200 | 4.5 | 6,2 | 4,6 |

| 250 | 5,1 | – | 5,1 |

Material

| Part | Material | Note |

| Diffuser section | Steel | – |

| Nozzle | Polyacetal POM | Colour options: White, Grey and Black |

| Plenum | Galvanised steel | – |

| Attenuation material | Polyester fibre | Cutting edges protected |

| Cover sleeve | Galvanised steel | Painted in diffuser colour |

| Coupling sleeve with gasket |

Galvanised steel | Gasket of rubber compound |

| Finishing | Painted, White (RAL 9003) |

Only front panel (TLD/A), special colours available |

Accessories

| Accessory | Code | Description |

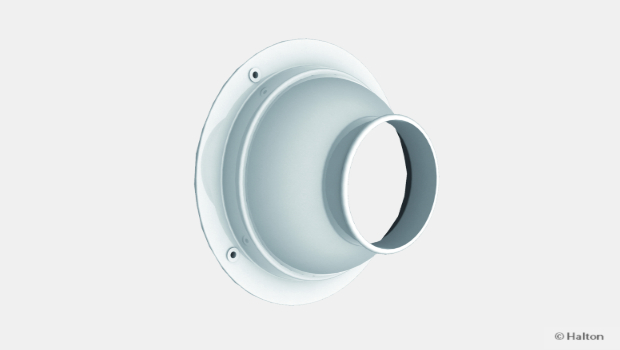

| Cover sleeve | CE | Cover sleeve for exposed installation (available only for back connection) |

Cover sleeve (CE)

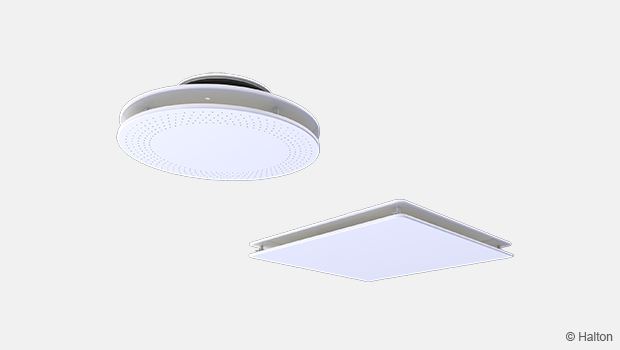

Product models

| Model | Description |

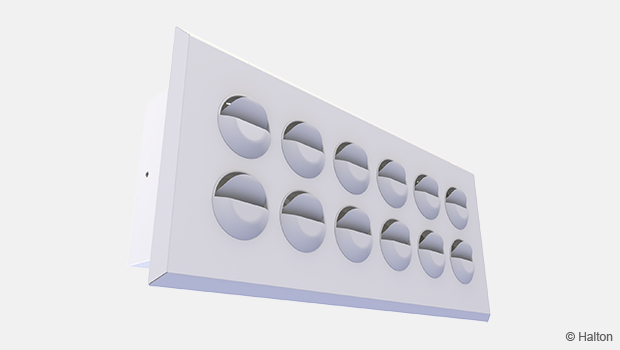

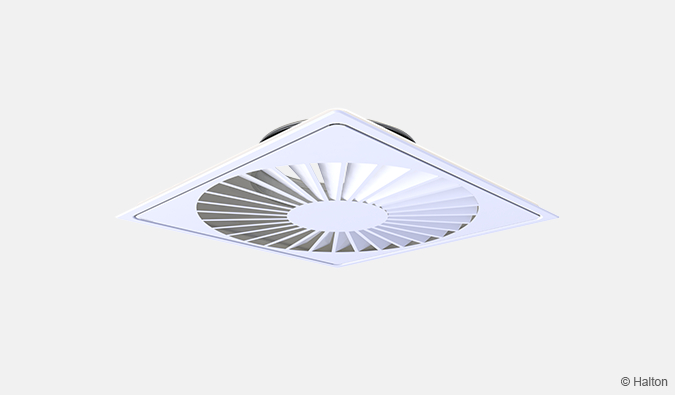

| TLD/A | Supply air unit, front plate (needing a plenum from below) |

| TLD/B | Plenum with back connection, supply (with MSM-module) |

| TLD/E | Plenum with side connection, supply (with MSM-module) |

Fig.1. TLD/A

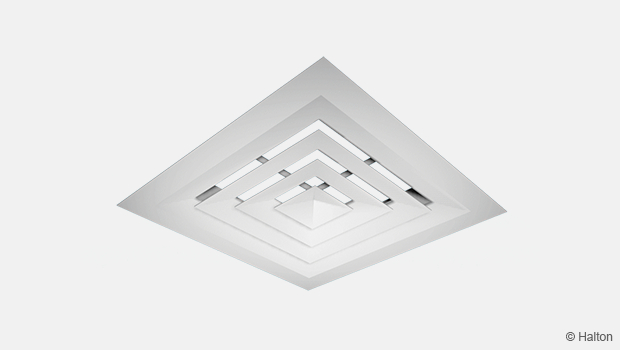

Fig.2. TLD/B Fig.3. TLD/E

Function

The nozzles of the diffuser direct the airflow obliquely toward the ceiling surface.

The supply air pattern can be directed by rotating the nozzles.

Direction of the supply air jet does not affect the pressure drop or the airflow rate.

The recommended maximum air temperature difference between supply and room air is 8 °C.

The maximum recommended operating temperature for the plastic material is 60 °C.

Note

The airflow pattern data has been prepared for a wall installation with a distance of 200 mm from the ceiling surface (I) for a direct discharge without ceiling (II).

Installation

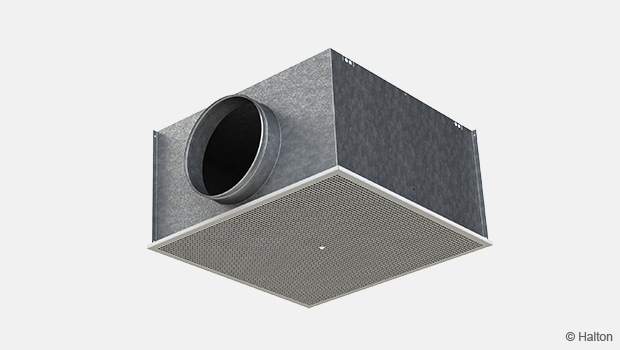

Code description

1. Diffuser section

2. Measurement and adjustment module (MSM/supply)

3. Plenum

The recommended installation distance below ceiling level is approx. 200 mm.

Installation opening

| NS | W2 x H2 |

| 100 | 405 x 155 |

| 125 | 405 x 205 |

| 160 | 505 x 205 |

| 200 | 705 x 255 |

| 250 * | 755 x 255 |

*) Only back connection available(TLD/B)

| NS | K1 |

| 80 | 75 |

| 100 | 85 |

| 125 | 85 |

| 160 | 100 |

| 200 | 125 |

| 250 * | 125 |

*) Only back connection available (TLD/B)

Do not fasten screws or rivets in the section at distance K1 from the front edge of the plenum, in order to keep the section clear for diffuser section (1) fastening.

Safety distance

The recommended minimum safety distance before the supply unit is 3xD.

Adjustment

The supply flow rate is determined by using measurement and adjustment module MSM. The tubes and control spindle are passed through the nozzles of the diffuser section, which is then replaced. Measure the differential pressure with a manometer.

The flow rate is calculated using the formula below (k-value in the bottom of page).

Adjust the airflow rate by rotating the control spindle until the desired setting is achieved. Lock the damper position with a screw. Replace the tubes and spindle in the diffuser section.

The k factor for installations with different safety distances

(D= duct diameter)

Supply air

| NS | > 8xD | min. 3xD |

| 100 | 5.8 | 6.4 |

| 125 | 9.4 | 12.6 |

| 160 | 16.1 | 22.0 |

| 200 | 26.9 | 32.7 |

| 250 * | 45.8 | 55.5 |

*) Only back connection (TLD/B)

The supply air pattern can be freely adjusted by rotating the nozzles manually.

Adjusting the nozzles

Servicing

Open the Halton TLD diffuser section, and remove the measurement and adjustment module by gently pulling from the shaft (not from the control spindle or measurement tubes).

Wipe the parts with a damp cloth, instead of immersing in water.

Reassemble the measurement and adjustment module by pushing the shaft until it meets the stopper.

The diffuser section is replaced by pushing it into the plenum until the springs lock.

Specification

The diffuser consists of a galvanised steel plenum and a detachable diffuser section made of epoxy-painted steel, with white (RAL 9003) as standard colour.

The detachable diffuser section includes adjustable nozzles and be attached to the plenum with invisible springs.

The wall diffuser unit has the supply air pattern obliquely toward the ceiling or directly forward. The ductwork connectionis be located at the back or side of the unit.

The throw pattern size and shape is adjustable individually by rotating the nozzles.

The diffuser provides access to the plenum and ductwork for cleaning and maintenance.

Order code

TLD/S-D, CO-ZT

S = Construction

A Diffuser section

B Plenum with duct connection on back (supply with MSM module)

E Plenum with duct connection on side (supply with MSM module)

D = Duct connection size (mm)

100, 125, 160, 200, 250

Other options and accessories

CO = Colour

SW Signal white (RAL 9003)

X Special colour (RAL xxxx)

ZT = Tailored product

N No

Y Yes (ETO)

Sub products

CE Cover sleeve (for back connection only, TLD/B)

Code example

TLD/A-100, CO=SW, ZT=N (Diffuser section)

TLD/B, ZT=N (Plenum, supply, back connection, MSM)

Downloads

"*" indicates required fields