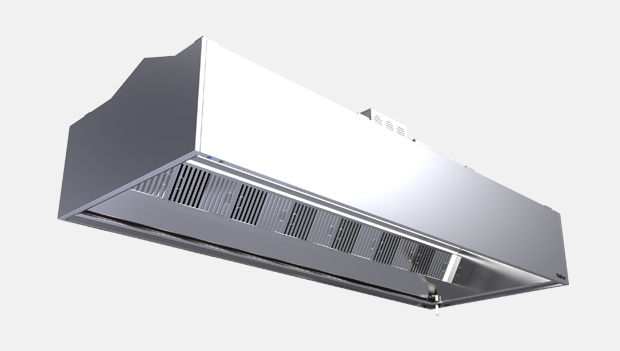

Product / USR-S

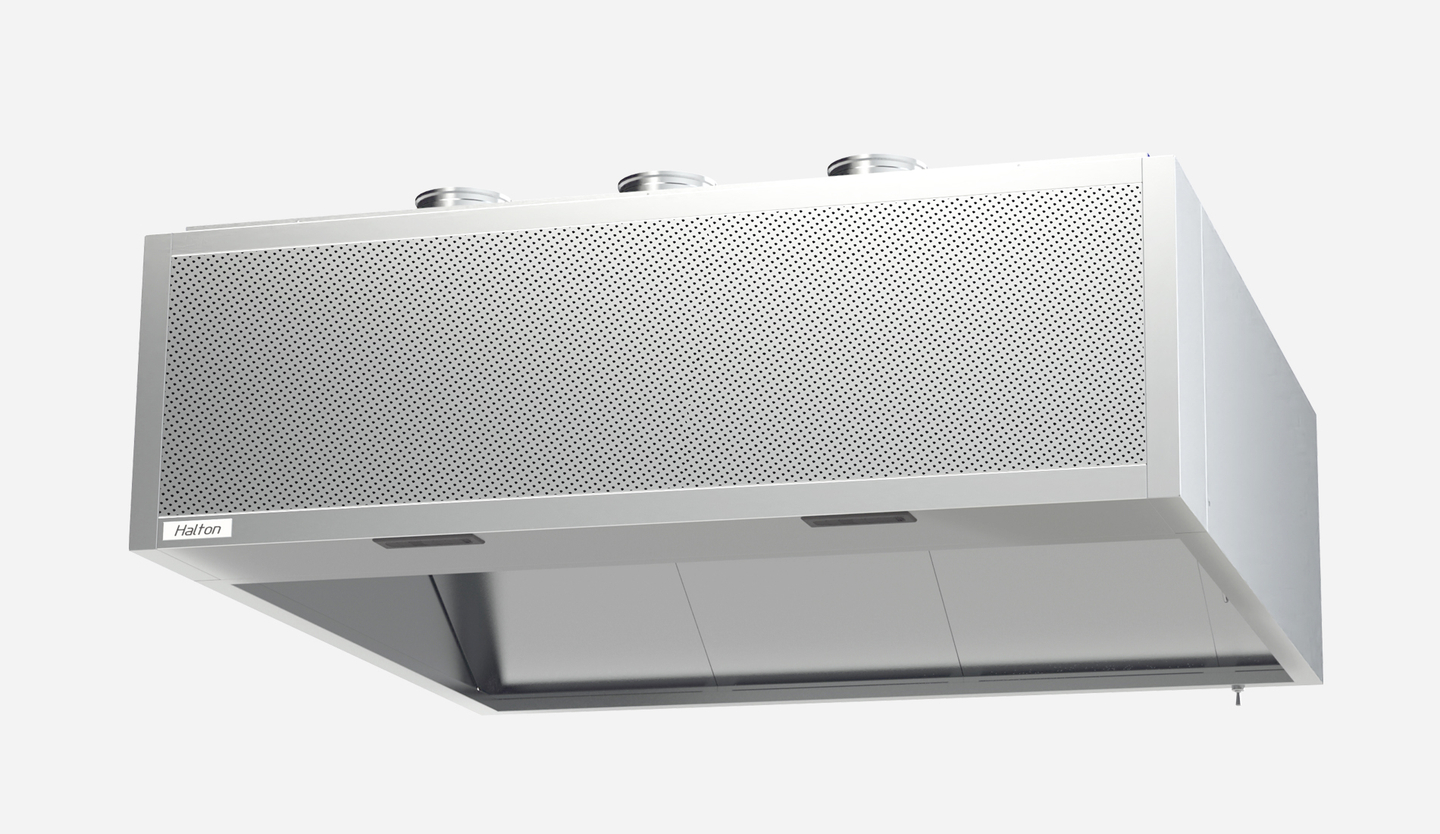

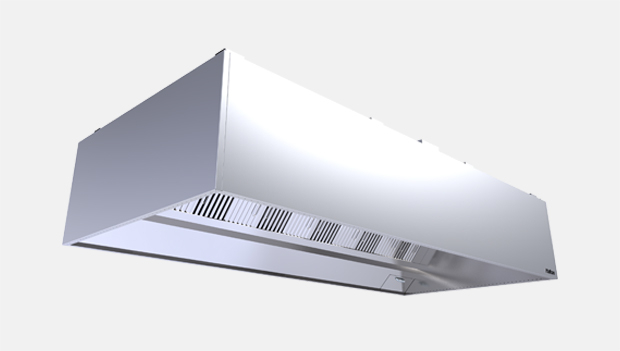

USR-S – Capture Ray™ low profile and suspended hood (CE)

Main features

◦ Special fryers ◦ Suspended model ◦ Capture Jet™ technology ◦ KSA aerosol separators ◦ UV-C Capture Ray™ technology ◦ Halton Skyline culinary & Human Centric Lighting ◦ Optional flat-packed delivery ◦ CE marked ◦ UKCA marked

Main benefits

- Ideal for frying and grilling hubs, especially in Quick Service Restaurants (QSR)

- Drastic energy savings thanks to reduced airflows

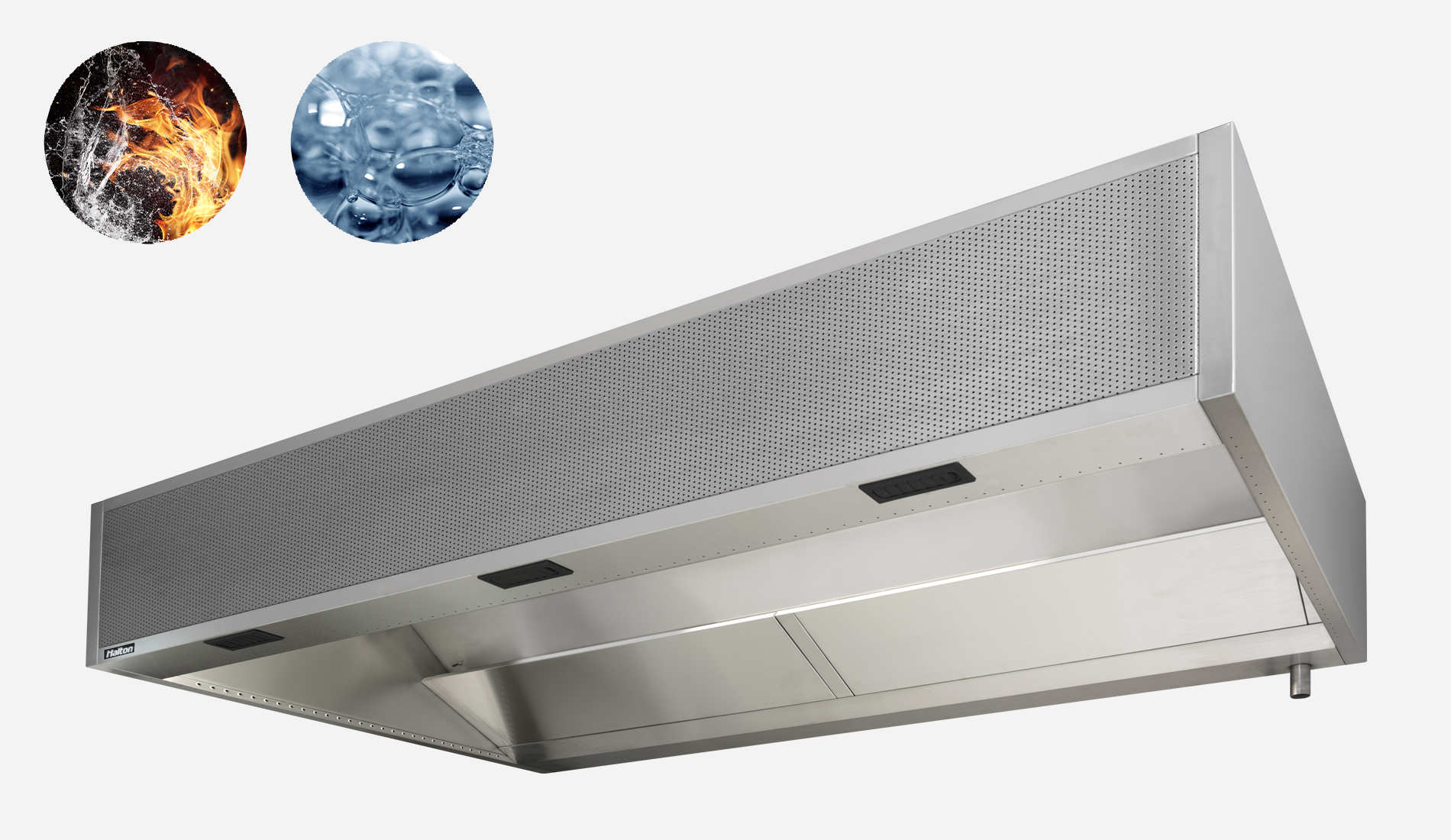

- Optimal fire safety, hygiene and reduced impact on neighborhood thanks to efficient grease and odors neutralization

- Allows for safe and efficient overtime heat recovery

- Drastic savings on ductwork cleaning thanks to the insignificant formation of grease deposits

- Improved visual comfort and color render for the food

Overview

Applications

Halton Capture Jet™ hoods and ventilated ceilings are suitable for all types of kitchens — closed, open, or show kitchens — and, in general, for all food-production environments.The model is more specifically designed for heavy steam-producing equipment used in central kitchens, Asian cooking, and similar applications.

Fully compatible with M.A.R.V.E.L. airflow and energy optimization technology, they are especially suitable for projects aiming for environmental or energy efficiency programs and certifications (such as LEED (1), BREEAM (2), DGNB (3), RE2020 (4), or similar) .

USR hoods are ideally suitable for frying and grilling hubs equipped with medium-duty electric appliances. In addition to the Capture Jets , they are also equipped with the Capture Ray™ technology. They are therefore more typically used for Ghost Kitchens or Quick Service Restaurants, especially in dense urban areas or when ducts are difficult to access.

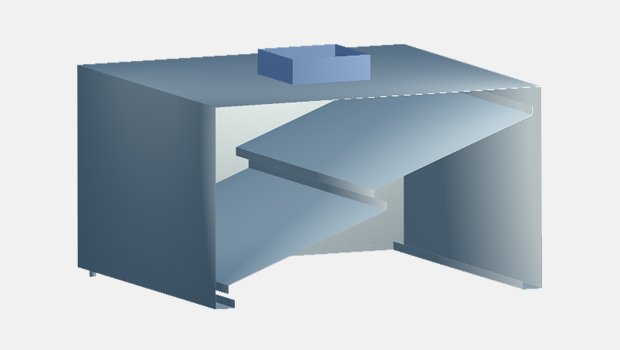

Description

The Capture Jet™ technology enables significant reductions in airflow rates leading to savings on construction costs, mainly due to the reduced size of ducts and HVAC equipment.

It typically pays for itself upon the startup of the kitchen or within few months. The energy savings it generates then directly contribute to an increase in profitability, while the staff benefits from improved working conditions.

USR hoods are installed closer to the cooking appliances; The smoke, steam, and heat released are then captured more efficiently. The Capture Jets combined with a capture “at closest from the source” reduce the exhaust airflow rates to the lowest possible level.

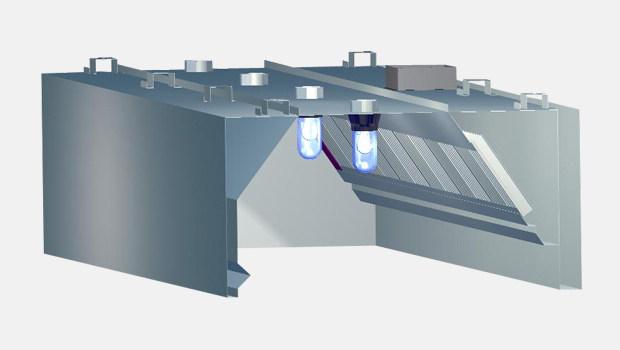

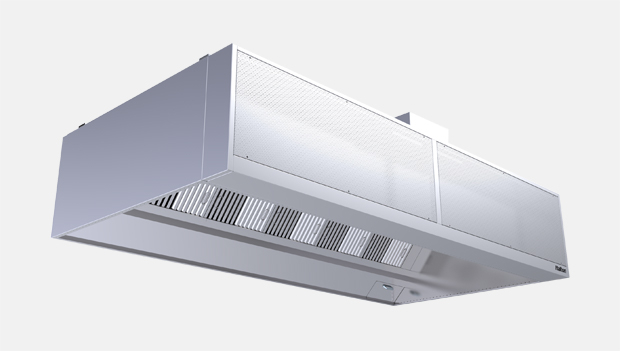

The Capture Ray™ technology neutralizes fine grease particles, grease vapors and a significant portion of the VOCs that cannot be removed by any primary mechanical filtration.

It offers a unique combination of benefits, including reduced cleaning costs, enhanced hygiene, improved fire safety, and a lower environmental impact on the surrounding neighborhood.

Considerable Energy Savings

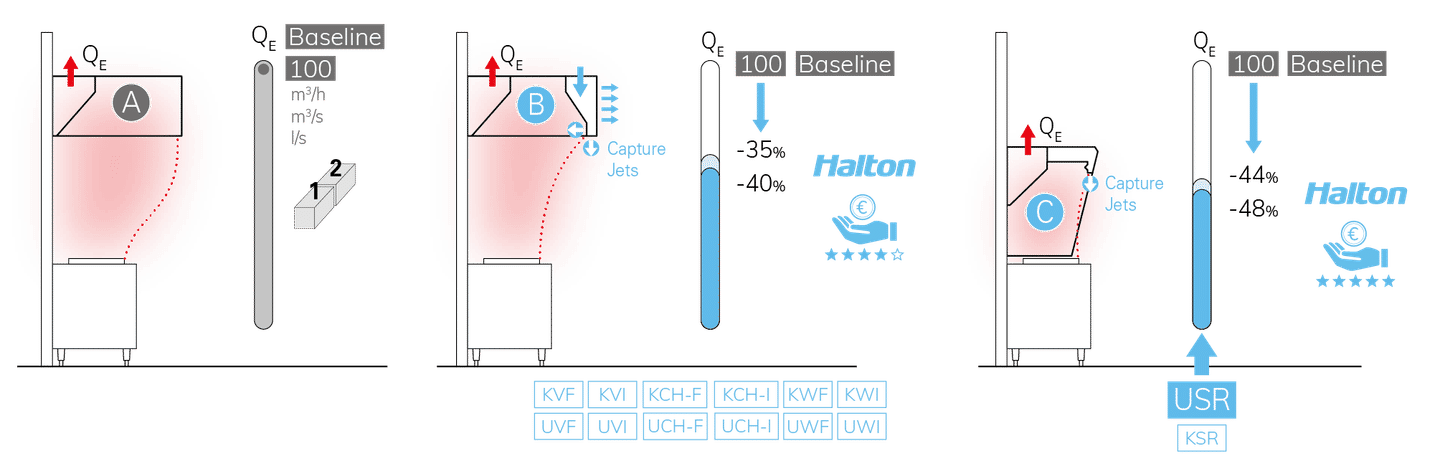

- The Capture Jet™ technology allows for up to a 48% reduction in exhaust airflow rates.

- The combination with M.A.R.V.E.L. airflow and energy optimization technology allows for drastically reducing the exhaust volumes on top of that achieved by the Capture Jets. This results in up to a 64%+ total reduction.

- The energy savings on heating/cooling the makeup air then become massive (less air out, less air in!).

- The reduction of the draft risk and noise levels also improves the working conditions for the staff.

Improved Safety, Maintenance Savings and Respect for the Neighborhood

- KSA cyclonic aerosol separators are constructed of stainless steel in compliance with EN 16282-6. They are up to 95% efficient at capturing particles of 10 microns or larger.

- KSA separators also have a good efficiency-to-pressure loss ratio and are certified UL 1046, NSF, and LPS 1263.

- On hoods, MFA mesh filters are used as as second filtration level to bring the total efficiency to up to 94% on 5 microns particles.

- The efficiency of KSA primary filtration is a prerequisite for the Capture Ray™ neutralization technology. It indeed achieves optimal efficiency on medium to small grease particles, grease vapors, and VOCs.

- The Capture Ray™ technology keeps the exhaust plenums and downstream ductwork virtualy free of grease deposits. Duct cleaning operations can be minimized, potentially limited to the legally required frequency (if applicable).

- Savings on ductwork cleaning costs are maximized and system uptime improved, while the hygiene and fire safety levels of the exhaust system are maintained at their highest standards.

- The Capture Ray™ technology also significantly reduces the odors discharged outdoor and thus lowers the kitchens’ environmental impact on the neighborhood and the risk of complaints or legal action.

- The UV On Demand option activates the lamps only when cooking appliances are actually used. It saves up to one lamps-set where other UV systems require two.

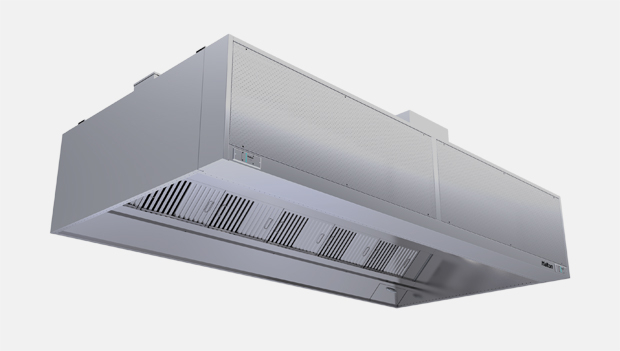

- Advanced 24/7 distant monitoring capabilities thanks to Halton Connect IoT (Internet of Things) platform.

- Highest value of ownership thanks to Halton Connect & Care smart services available as an option from kitchens commissioning.

Other Benefits and Features

- Construction compliant with NF EN 16282-2 (5).

- Minimum space used.

- Integrated fan to supply air to the Capture Jets. No connection to the supply ductwork is required.

- The Capture Jets are automatically switched off when the ventilation system is turned off or operates at minimum airflow.

- Total access security to UV-C lamps. Includes a presence check for each filter and verification of the correct closing of the access hatch to the UV lamps.

- Halton Skyline (HCL) LED culinary light provides the best visual comfort while contributing to further improve safety and energy savings.

- When extended to the whole kitchen and surrounding areas, the Human Centric version of Halton Skyline (HCL) directly contributes to chefs’ and their teams wellbeing.

- Exhaust airflow rates are determined using an EN 16282-1 based calculation method, which takes into account the loads of the cooking or dishwashing equipment, the makeup air strategy, the configuration of the hoods or ventilated ceilings, and their capture and containment efficiency.

- Capture and containment efficiency tested in accordance with the ASTM 1704 standard.

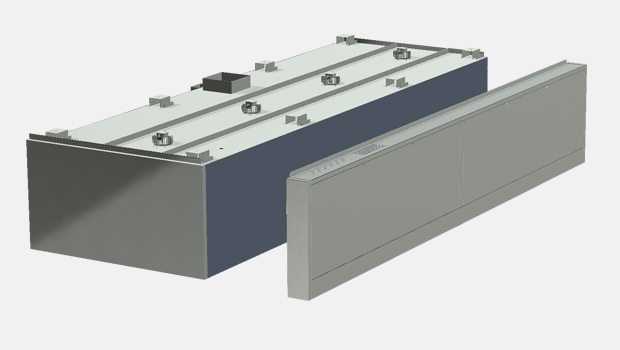

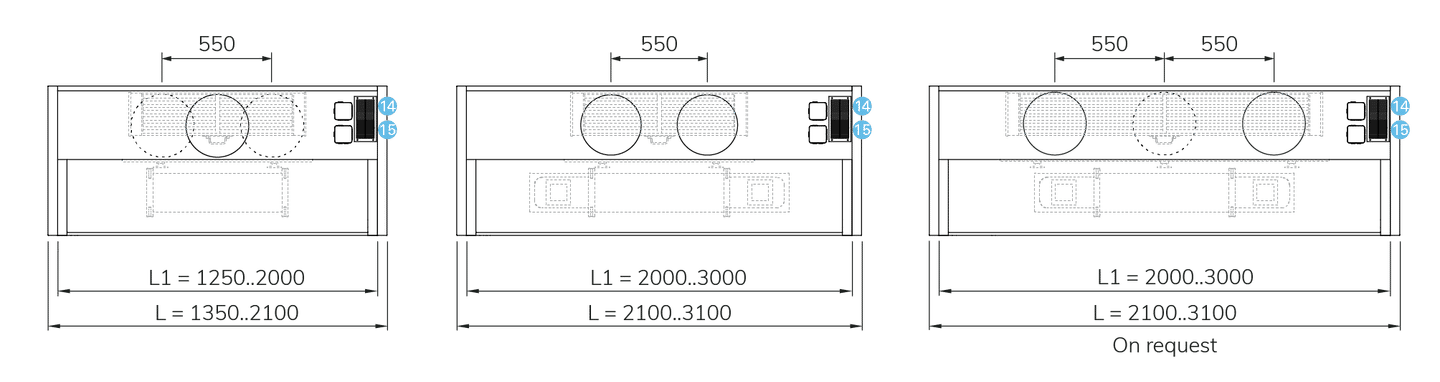

- Modular design allowing for assembling several sections without separation between modules.

- Quick and easy commissioning. Hoods delivered “ready to install”, with all accessories included, such as light fitting, T.A.B.™ airflow measurement taps, and dampers for quick balancing on-site.

- Sturdier and easier to clean (less parts and fewer joints). Stainless steel construction.

(1) LEED – Leadership in Energy and Environmental Design (2) BREEAM – Building Research Establishment Environmental Assessment Method (3) DGNB – German Sustainable Building Council (4) RE2020 – French Environmental Regulation 2020 (5) EN 16282-2 Equipment for commercial kitchens – Components for ventilation in commercial kitchens – Part 2 : kitchen ventilation hoods – Design and safety requirements (6) HACCP – Hazard Analysis Critical Control Point

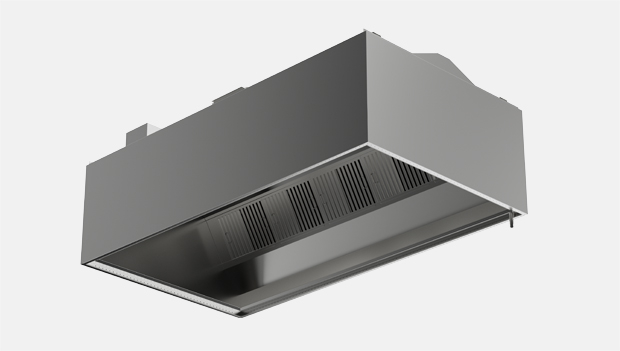

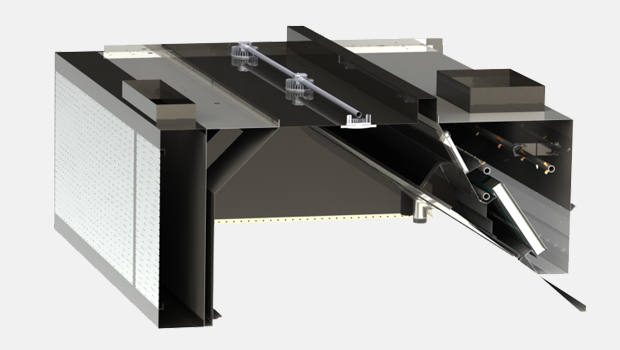

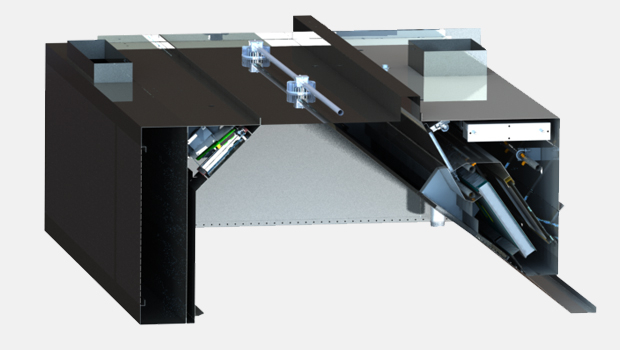

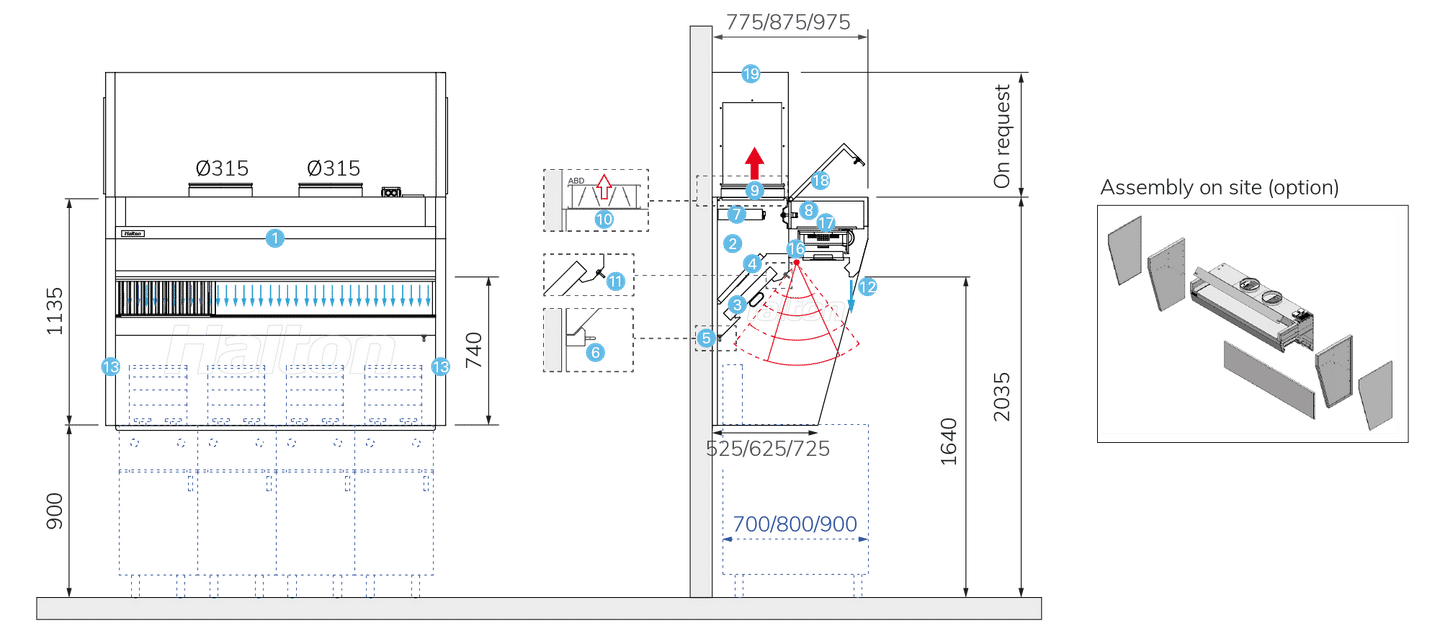

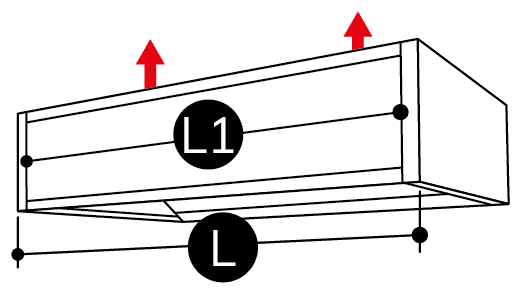

Construction and Dimensions

- Exhaust plenum construted from stainless steel AISI 304 (1 mm thick) and galvanized steel (plenum’s top)

- KSA aerosol separator.

- MFA filters as second filtration stage.

- Condensates drain.

- Collection tray as an option.

- UV-C lamps cassette mounted on runners for an easy removal.

- UV access hatch for a quick access to the UV lamps for cleaning.

- Exhaust connection(s) and sliding damper(s).

- When the kitchen is equipped with M.A.R.V.E.L. airflow and energy optimization technology (MRV), the sliding damper is replaced by ABD automated balancing damper.

- T.A.B.™ (Testing And Balancing) pressure port(s) for quick airflow calculation during ductwork balancing operations.

- Front Capture Jet™ nozzles.

- Double skin sides.

- Integrated Capture Jet™ fan.

- Capture Jet™ fan air inlet.

- Halton Thermal Imaging sensor (used for the optional M.A.R.V.E.L., UV on Demand or FireWatch technologies).

- Halton Skyline LED culinary LED light fitting integrated on a flush-mounted access hatch.

- Maintenance access hatch.

- [Option] stainless steel cover board with access hatches.

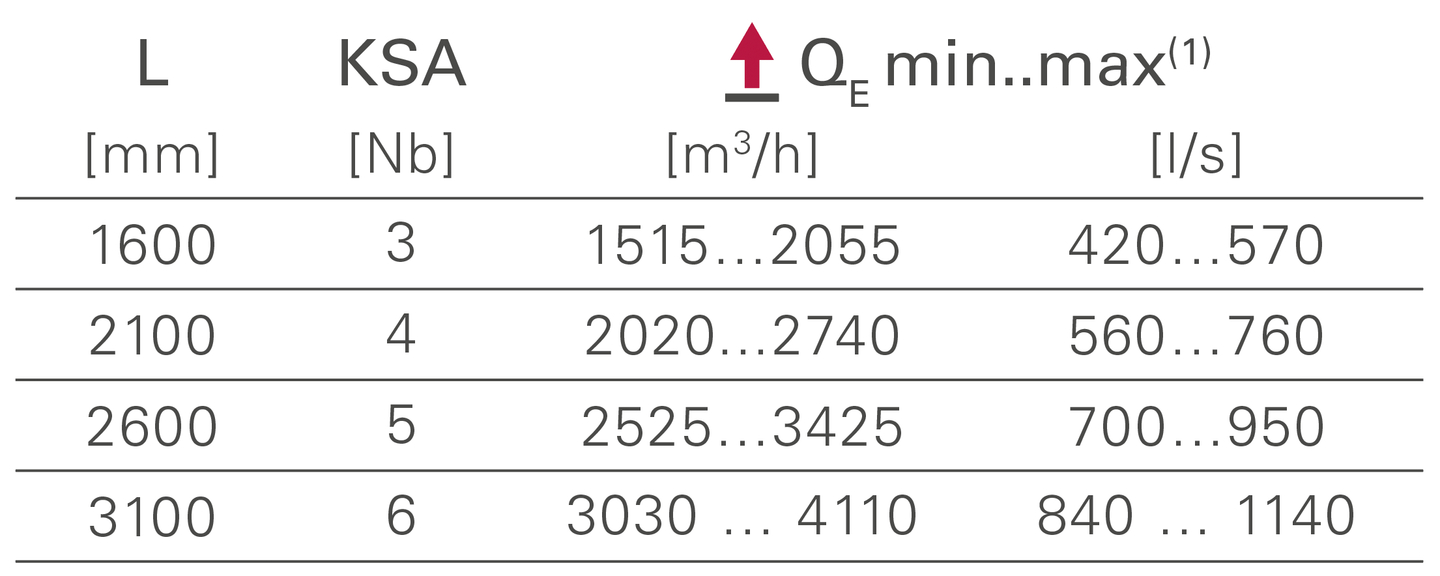

Admissible and Calculated Airflows

Admissible airflows

Calculated airflows

The calculated exhaust airflow rates are determined with a EN 16282-1 based calculation method. It relies on the evaluation of the convective flows’ volume (air mixed with heat, steam, grease, smoke and other pollutants) generated by the cooking appliances, depending on their type, on the energy they use and their installation conditions (central, on a wall, in an angle).

The air volume required to remove the convective loads is then calculated depending on:

- The hood or ventilated ceiling installation height;

- The makeup-air strategy (mixing or displacement);

- The hood or ventilated ceiling capture efficiency according to ASTM 1704-12 standard.

USR hood reduces the exhaust airflow rates(1) by up to 48% compared to traditional hoods.

(1) This scale is indicative and based on wall mounted hoods, opened on 3 sides, equipped with a same cooking bloc, whatever it is. The variation in exhaust airflow reduction for a given hood type is due to the makeup-air type (mixing or displacement). Other parameters do impact the final airflow rates. Our sales teams are at your disposal to provide you with a calculation note, depending on your kitchen configuration.

Downloads

Request for Quotation

"*" indicates required fields