Product / PLD

Overview

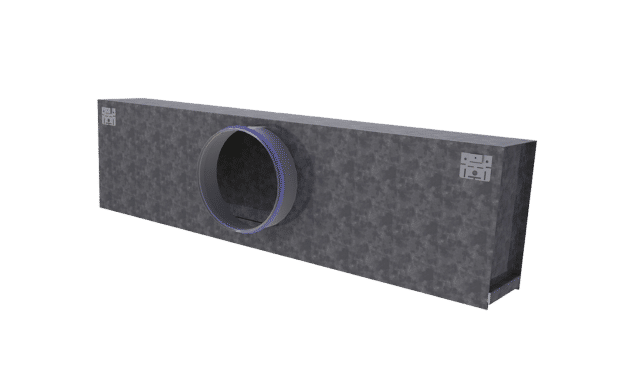

- Plenum for connecting Halton SLL and SLN linear slot diffuser supply/exhaust unit to ductwork

- Ensures proper function of the air diffuser

- Access for ductwork cleaning

Product models and accessories

A detachable airflow rate measurement and balancing module is available.

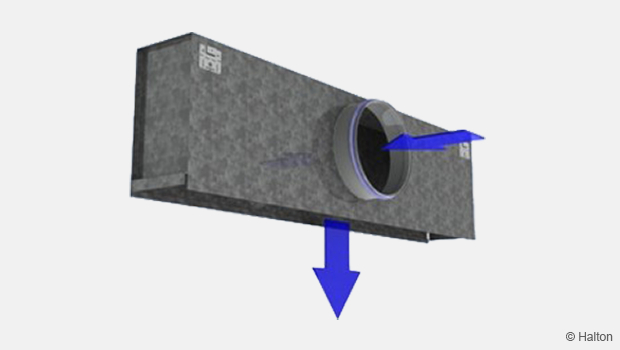

Operating principle

The duct pressure and air velocity are reduced inside the Halton PLD plenum box.

Air is supplied into the space through the diffuser, improving the air distribution quality.

When the Halton PLD is supplied equipped with a measurement and adjustment unit, the volume flow rate can be balanced.

Features and options

| Category | Feature (Order code) | Option (Order code) | Description |

| Sound attenuator | Sound attenuation material (IN) |

N | No attenuation material |

| 2W | 2 sides, Mineral wool | ||

| 5W | 5 sides, Mineral wool | ||

| 2P | 2 sides, Polyester fibre | ||

| 5P | 5 sides, Polyester fibre | ||

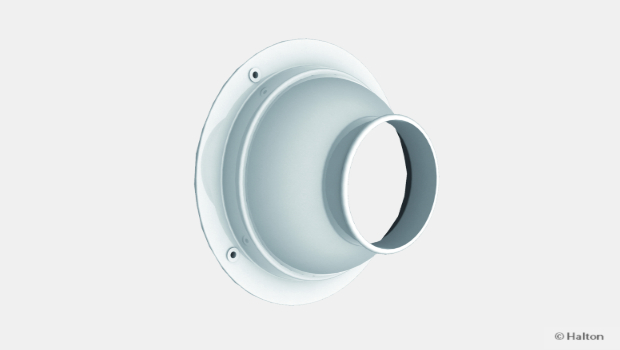

| MSM | Airflow measurement and adjustment unit (OM) |

N | No measurement or adjustment module |

| Y | MSM installed in each duct connection | ||

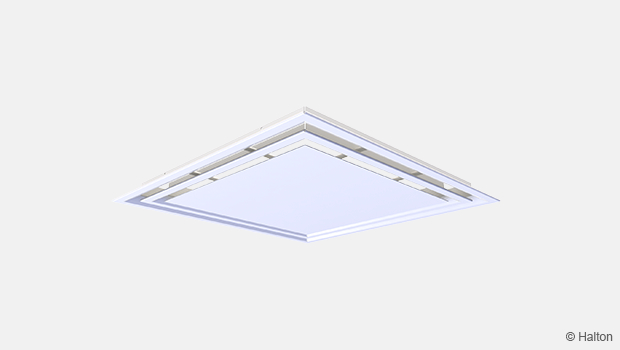

| Filter | Filter for exhaust (FO) | N | No filter : supply or exhaust application |

| Y | Filter : exhaust with filter (need a SLL/O) | ||

| Spigot | Spigot type (SG) | G | Spigot with gasket |

| W | Spigot without gasket |

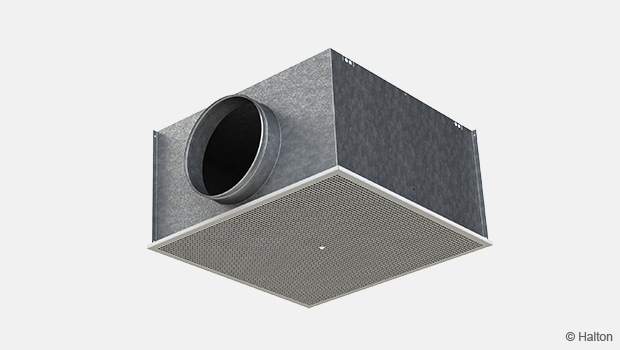

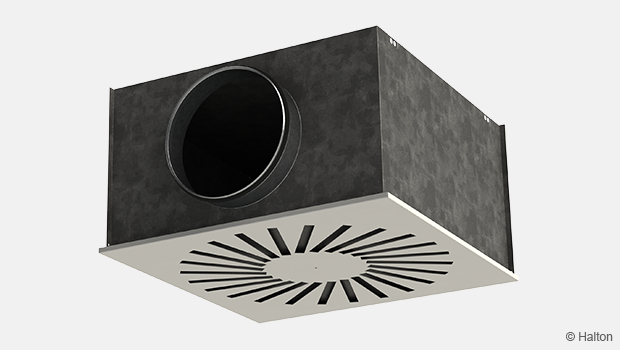

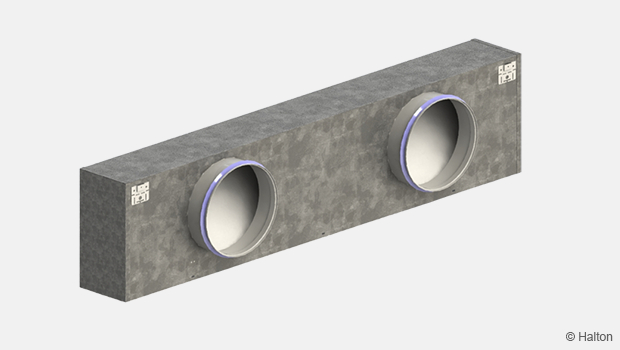

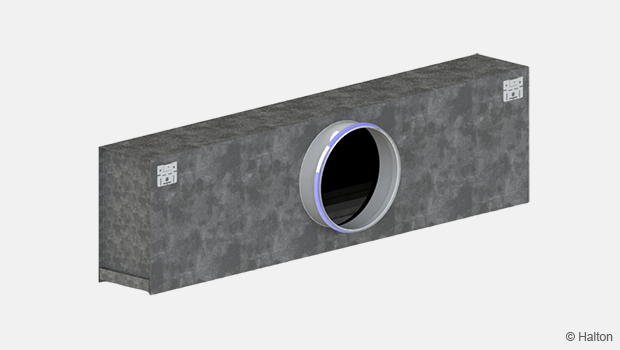

Halton PLD with filter (FO=Y)

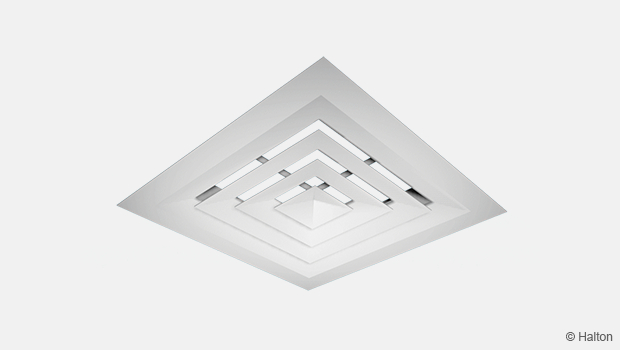

Halton PLD without filter (FO=N)

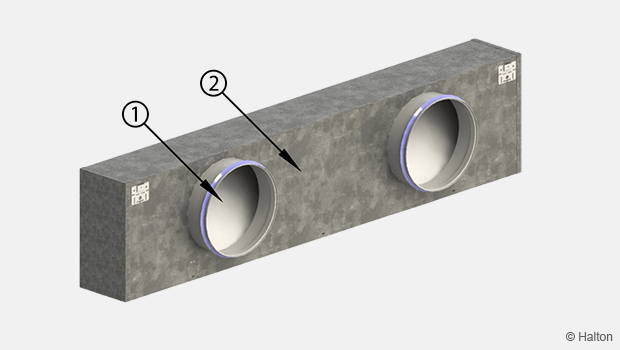

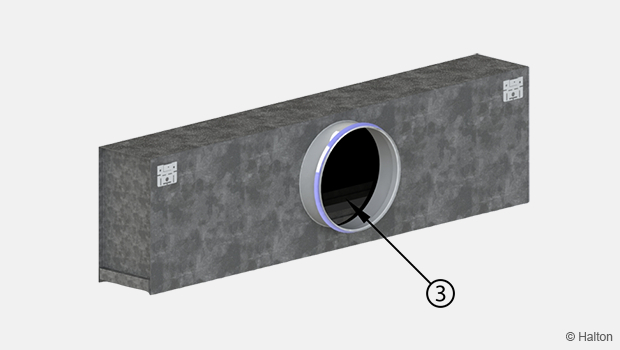

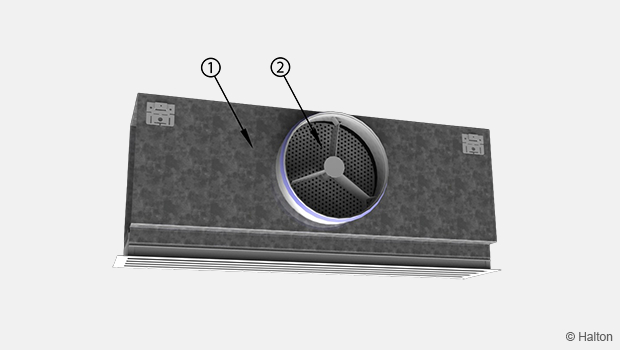

Structure and materials

| No. | Part | Material | Note |

| 1 | Filter | Polyester fiber | Option when FO = Yes |

| 2 | Plenum box / spigot | Galvanised steel | Spigot equipped with rubber gasket |

| 3 | Sound attenuation material | Mineral wool or polyester fibre | The mineral wool is fixed with nails |

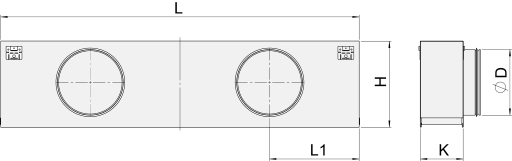

Dimensions

Halton PLD, without filter – dimensions

| Slots | PH | K | ØD | |

| PH = S | PH = R | |||

| 1 | 235 | D+75 | 47 | 125, 160 |

| 2 | 275 | 85 | 125, 160, 200 | |

| 3 | 325 | 123 | 125, 160, 200 | |

| 4 | 325 | 161 | 125, 160, 200, 250 | |

| 5 | 325 | 199 | 125, 160, 200, 250 | |

| 6 | 325 | 237 | 125, 160, 200, 250 | |

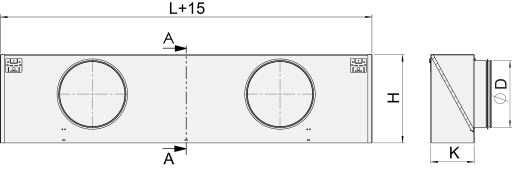

Halton PLD, with filter – dimensions

| Slots | PH | K | ØD | |

| PH = S | PH = R | |||

| 3 | 325 | D+75 | 121 | 125, 160, 200 |

| 4 | 325 | 139 | 125, 160, 200, 250 | |

| 5 | 325 | 197 | 125, 160, 200, 250 | |

| 6 | 325 | 235 | 125, 160, 200, 250 | |

Standard dimensions for linear slot diffusers

| Diffuser active length [mm] | 572 | 872 | 1172 | 1472 | 1772 |

| L (mm) | 571 | 871 | 1171 | 1471 | 1771 |

| L1 (mm) | 286 | 436 | 586 | 368 | 443 |

| Duct connections (pcs) | 1 | 1 | 1 | 2 | 2 |

In addition to standard linear slot diffuser sizes, other sizes can be ordered. The maximum length is 2000 mm.

However, continuous plenums with modular design are also available for installation lengths greater than 2000 mm.

Specification

Function

- The plenum reduces duct pressure and air velocity in order to supply air throughout the entire face area of the linear diffuser and improve the air distribution quality.

Structure

- The plenum comprises an airflow measurement and adjustment module.

- The diffuser is detachable in order to provide access to the measurement and adjustment module in the plenum.

Materials

- The plenum is made of galvanised steel.

Installation

| No. | Part |

| 1 | Plenum |

| 2 | Measurement and adjustment module |

- The plenum is installed into the suspended ceiling with M8 drop rods (not supplied in the delivery).

- Connect the plenum to the ductwork with a spigot equipped with an integrated rubber gasket.

- When equipped with a measurement and adjustment module, the recommended safety distance upstream of the device is at least 3D, in order to ensure a reliable airflow rate measurement.

The unit s control spindle must not be excessively bent.

Note : When Halton PLD is equipped with a filter, then rivets or screws must be used to fix the diffuser to the plenum

Commissioning

In order to enable airflow adjustment and measurement of airflow rate, it is recommended that you connect the diffuser to the plenum equipped with the MSM module.

The supply flow rate is determined by using the measurement and adjustment module MSM.

Detach the linear slot diffuser and pass the tubes and control spindle through the diffuser.

Replace the diffuser / exhaust unit.

Measure the differential pressure using a manometer. The flow rate is calculated using the formula below:

| ∆pm | Measured pressure [Pa] |

| k | k factor given as a function of mounting and diameter |

| qv | Airflow rate [l/s] |

The k-factor for installations with different safety distances

(D= duct diameter)

| Duct connection (PLD) | k-factor of MSM adjuster, opening > 0 [l/s] | |

| > 6D | min 3D | |

| 160 | 19 | 22 |

| 200 | 28 | 32 |

| 250 | 49 | 51 |

Adjust the airflow rate by rotating the control spindle until the desired setting is achieved.

Lock the damer position with a screw.

Replace the tubes and spindle into the plenum and replace the diffuser.p

Maintenance

Remove the measurement and adjustment module by gently pulling the shaft (not the control spindle).

Wipe the parts with a damp cloth, instead of immersing in water.

Reassemble the measurement and adjustment module by pushing the shaft back into place until the module meets the stopper.

Order code

PLD-S-L-D-N; FO-PH-IN-SG-OM-ID-ZT

| Main options | |

| S = Number of slots | 1, 2, 3, 4, 5, 6 |

| L = Length [mm] | 372,+1,..,49972 |

| D = Duct connection size [mm] | 120, 160, 200, 250 |

| N = Number of duct connections | 1, 2, …+1, … 322 |

| Other options and accessories | |

| FO = Filter option | |

| N | No |

| Y | Yes |

| PH = Plenum height | |

| S | Standard |

| M | Reduced (d + 75 mm) |

| In = Sound attenuation material | |

| N | No |

| 2W | 2 sides, mineral wool |

| 5W | 5 sides, mineral wool |

| 2P | 2 sides, polyester fibre |

| 5P | 5 sides, polyester fibre |

| SG = Spigot type | |

| G | With gasket (standard) |

| W | Without gasket |

| OM = Measurement/adjustment module (MSM) | |

| N | No |

| Y | Yes |

| ID = Diffuser assembled with plenum | |

| N | No |

| Y | Yes |

| ZT = Tailored product | |

| N | No |

| Y | Yes (ETO) |

Order code example

PLD-4-1972-250-2; FO=N, PH=S, IN=2W, OM=N, ID-N, ZT=N

Downloads

"*" indicates required fields