Product / THL

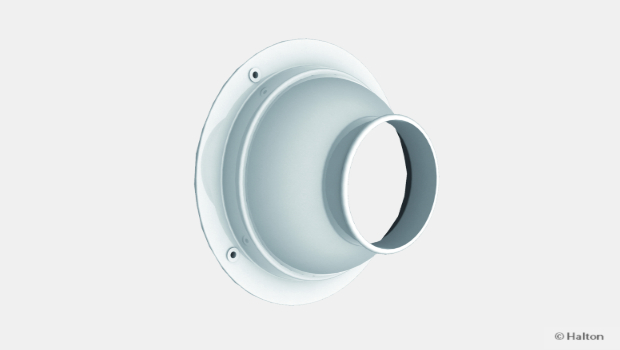

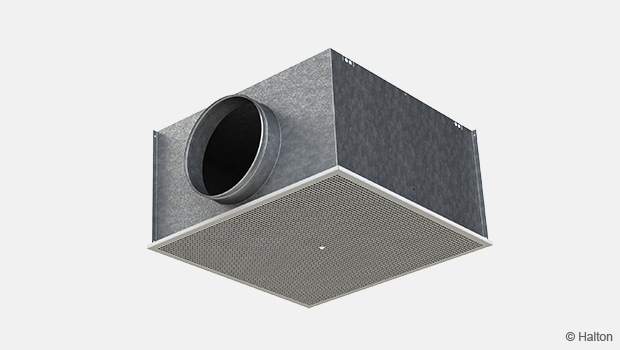

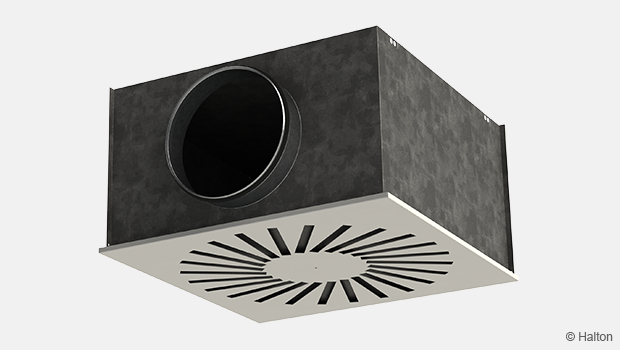

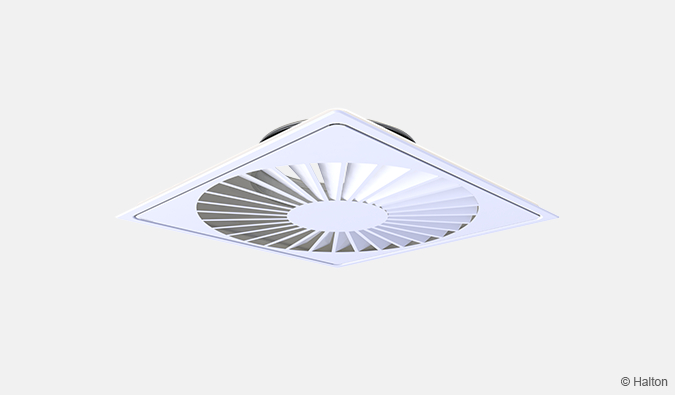

Halton THL – Conical diffuser

Circular conical diffuser for ceiling installation. Ideal for high spaces and easy to clean and maintain.

- Suitable for both heating and cooling applications

- Adjustable throw pattern (radial or compact jet)

Overview

- Horisontal or vertical air supply

- Suitable for both heating and cooling applications

- Adjustable throw pattern (radial or compact jet)

- Installation flush to the ceiling, or exposed (especially in high spaces)

- Circular duct connection with gasket

- Openable front disk enables cleaning of the diffuser and ductwork

Accessories

- Plenum options with measurement and adjustment functions

Quick selection

Fig.1. Halton THL with TRH plenum.

Fig.1. Halton THL with TRH plenum.

Dimensions

Halton THL, manual

| NS | ØW | H | H1 | H2 | ØD |

| 100 | 286 | 105 | 63 | 9 | 99 |

| 125 | 286 | 105 | 63 | 9 | 124 |

| 160 | 286 | 80 | 48 | 9 | 159 |

| 200 | 354 | 90 | 49 | 10 | 199 |

| 250 | 438 | 96 | 45 | 11 | 249 |

| 315 | 544 | 118 | 51 | 13 | 314 |

| 400 | 682 | 149 | 65 | 14 | 399 |

Halton THL with wax-bulb actuator

| NS | ØW | H | H1 | H2 | ØD |

| 250 | 438 | 96 | 45 | 11 | 249 |

| 315 | 544 | 118 | 51 | 13 | 314 |

| 400 | 682 | 149 | 65 | 14 | 399 |

Material

| Key | Part | Description | Note |

| 1 | Duct seal gasket | Rubber | – |

| 2 | Frame | Steel | Powder paint, white (RAL 9003). Special colours available on request. |

| 3 | Front disk | Steel | Powder paint, white (RAL 9003). Special colours available on request. |

Accessories

| Accessory | Code | Description |

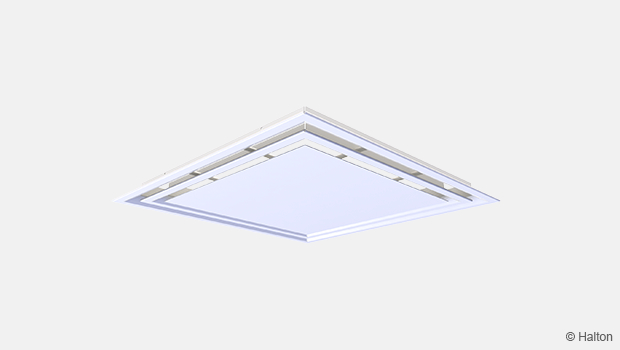

| Balancing plenum | TRI | For balancing, equalising the airflow and attenuating the duct noise (polyesterfibre) |

| Balancing plenum | TRH | For balancing, equalising the airflow and attenuating the duct noise (mineral wool and polyester fibre) |

Product models

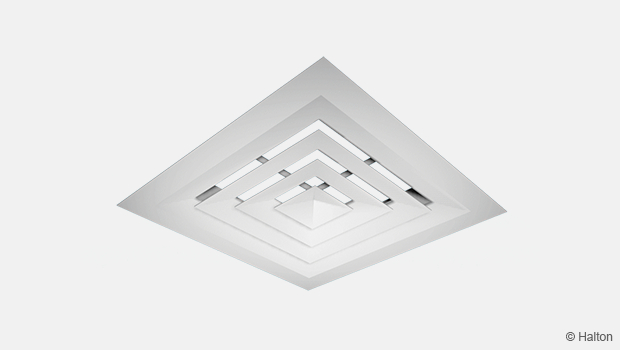

Halton THL, manually operated

Changing manually the front disk position the throw pattern can be adjusted from radial to compact.

Halton THL with wax-bulb actuator

Sizes 250, 315 and 400 can be equipped with a wax-bulb actuator, which work without any power supply. The front disk position changes according to the temperature of supply air. The temperature range of the wax-bulb actuator is about 20 °C to 27 °C.

The time taken to change from radial to compact jet (or the other way around) is 10 – 20 minutes.

When warm air is supplied the piston of the wax bulb actuator keeps moving until the THL supply air pattern is vertical. When cold air is supplied, the Halton THL supply air pattern is changed back to horizontal by means of a spring.

Function

Compact jet Radial jet

The Halton THL is a ceiling diffuser with an adjustable low pattern.

The horisontal radial jet is used mainly in cooling applications and the vertical compact jet with warm supply air in heating applications.

The supply air pattern can be adjusted by rotating the front disk into the desired position.

The recommended maximum temperature difference in cooling applications between supply and room air temperature is 10 °C.

Installation

Code description

1. Front disk

2. Frame

The diffuser is connected either directly to the duct by screwing or riveting or alternatively to the Halton TRI balancing plenum.

The minimum recommended safety distance upstream of the diffuser is 3xD.

Installation with Halton TRI

The collar of Halton TRI plenum can be installed either internally in the plenum or externally onto the bottom of the plenum.

The height of the unit for the external installation is presented in the table below.

| THL | ØW | TRI | ØD | ØD1 | W1 | L | L1 | H | H1 min | H2 max |

| 100 | 286 | 100-100 | 99 | 102 | 282 | 308 | 154 | 152 | 100 | 135 |

| 125 | 286 | 100-125 | 99 | 127 | 282 | 308 | 154 | 152 | 100 | 135 |

| 125 | 286 | 125-125 | 124 | 127 | 432 | 458 | 229 | 182 | 100 | 135 |

| 160 | 286 | 100-160 | 99 | 162 | 282 | 308 | 154 | 152 | 90 | 105 |

| 160 | 286 | 125-160 | 124 | 162 | 432 | 458 | 229 | 182 | 90 | 105 |

| 160 | 286 | 160-160 | 159 | 162 | 432 | 458 | 229 | 222 | 90 | 105 |

| 200 | 354 | 125-200 | 124 | 202 | 432 | 458 | 229 | 182 | 98 | 114 |

| 200 | 354 | 160-200 | 159 | 202 | 432 | 458 | 229 | 222 | 98 | 114 |

| 200 | 354 | 200-200 | 199 | 202 | 592 | 618 | 309 | 272 | 98 | 114 |

| 250 | 438 | 160-250 | 159 | 252 | 432 | 458 | 229 | 272 | 107 | 119 |

| 250 | 438 | 200-250 | 199 | 252 | 592 | 618 | 309 | 272 | 107 | 119 |

| 250 | 438 | 250-250 | 249 | 252 | 592 | 618 | 309 | 336 | 107 | 119 |

| 315 | 544 | 200-315 | 199 | 317 | 592 | 618 | 309 | 336 | 121 | 139 |

| 315 | 544 | 250-315 | 249 | 317 | 592 | 618 | 309 | 336 | 121 | 139 |

| 315 | 544 | 315-315 | 314 | 317 | 592 | 618 | 309 | 336 | 121 | 139 |

| 400 | 682 | 200-400 | 199 | 402 | 592 | 618 | 309 | 382 | 137 | 169 |

| 400 | 682 | 250-400 | 249 | 402 | 592 | 618 | 309 | 382 | 137 | 169 |

Installation with Halton TRH

| THL | ØW | TRH | ØD | ØD1 | W1 | L | L1 | H | H1 min. | H2 max. |

| 100 | 286 | 100-100 | 99 | 102 | 281 | 281 | 141 | 152 | 89 | 124 |

| 125 | 286 | 100-125 | 99 | 127 | 281 | 281 | 141 | 152 | 89 | 124 |

| 125 | 286 | 125-125 | 124 | 127 | 431 | 431 | 216 | 180 | 89 | 124 |

| 160 | 286 | 100-160 | 99 | 162 | 281 | 281 | 141 | 152 | 79 | 94 |

| 160 | 286 | 125-160 | 124 | 162 | 431 | 431 | 216 | 180 | 79 | 94 |

| 160 | 286 | 160-160 | 159 | 162 | 431 | 431 | 216 | 212 | 79 | 94 |

| 200 | 354 | 125-200 | 124 | 202 | 431 | 431 | 216 | 180 | 87 | 103 |

| 200 | 354 | 160-200 | 159 | 202 | 431 | 431 | 216 | 212 | 87 | 103 |

| 200 | 354 | 200-200 | 199 | 202 | 400 | 550 | 355 | 245 | 87 | 103 |

| 250 | 438 | 160-250 | 159 | 252 | 431 | 431 | 216 | 212 | 96 | 108 |

| 250 | 438 | 200-250 | 199 | 252 | 400 | 550 | 355 | 245 | 96 | 108 |

| 250 | 438 | 250-250 | 249 | 252 | 450 | 600 | 378 | 295 | 96 | 108 |

| 315 | 544 | 200-315 | 199 | 317 | 400 | 550 | 355 | 245 | 110 | 128 |

| 315 | 544 | 250-315 | 249 | 317 | 450 | 600 | 378 | 295 | 110 | 128 |

| 315 | 544 | 315-315 | 314 | 317 | 500 | 650 | 398 | 360 | 110 | 128 |

| 400 | 682 | 250-400 | 249 | 402 | 450 | 600 | 378 | 295 | 126 | 158 |

| 400 | 682 | 315-400 | 314 | 402 | 500 | 650 | 398 | 360 | 126 | 158 |

Adjustment

The Halton THL itself has no means for airflow adjustment.

In order to enable airflow adjustment and measurement of airflow rate it is recommended that the diffuser be connected to the Halton TRH or TRI balancing plenum. The supply airflow rate is determined by using the measurement and adjustment module MSM.

Detach the front disk or the whole diffuser and pass the tubes and control spindle through the side slot of the diffuser.

Replace the front disk or diffuser.

Measure the differential pressure using a manometer. The airflow rate is calculated using the formula below.

Adjust the airflow rate by rotating the control spindle until the desired setting is achieved.

Lock the damper position with a screw.

Replace the tubes and spindle into the plenum.

The k-factor for installations with different safety distances (D= duct diameter)

| TRI | > 8 x D | min 3 x D |

| 100 | 6.0 | 7.5 |

| 125 | 9.9 | 12.6 |

| 160 | 16.9 | 21.9 |

| 200 | 28.3 | 31.0 |

| 250 | 47.9 | 51.5 |

| 315 | 78.6 | – |

The technical performance has been defined for radial and compact jet with the fixed cone module openings. The adjustment positions used are detailed in the table below.

| THL (R) | THL (C) | |

| Size | Radial jet | Compact jet |

| 100 | 8 | -4 |

| 125 | 10 | -4 |

| 160 | 12 | 0 |

| 200 | 15 | 0 |

| 250 | 19 | 0 |

| 315 | 24 | 0 |

| 400 | 30 | 0 |

Servicing

Measure the distance between the front disk and the upper frame in order to enable recovery of the same technical properties after cleaning.

Detach the front disk of the diffuser and clean the parts by wiping with a damp cloth.

Reinstall the front panel.

Specification

The ceiling diffuser has a steel casing with an adjustable front disk and a spigot with integral gasket for connection to the circular duct.

The diffuser is polyester or painted white (RAL 9003) colour.

The throw pattern of the diffuser is adjustable in radial or compact jet.

Order code

THL/D-A, CO-MO-ZT

| Main options | |

| D = Diffuser duct connection size [mm] | 100, 125, 160, 200, 250, 315,4 00 |

| Other options and accessories | |

| CO = Colour | |

| SW | Signal white (RAL 9003) |

| X | Special colour (RAL xxxx) |

| MO = Actuator | |

| NA | Not assigned |

| M1 | Wax-bulb actuator |

| ZT = Taylored product | |

| N | No |

| Y | Yes (ETO) |

| Sub products and accessories (ordered separately) | |

| Halton Pop PDI | Balancing plenum |

Order code example

THL-200; CO=SW, MO=NA, ZT=N

Downloads

"*" indicates required fields