Product / PDI

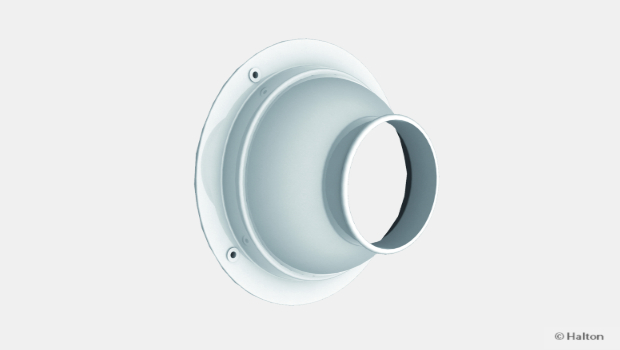

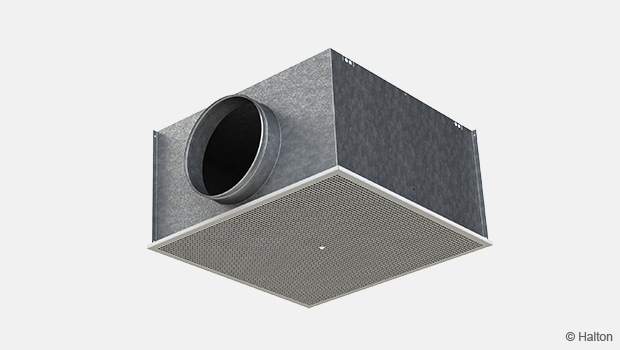

Halton Pop PDI – Plenum for diffusers

The Halton Pop PDI balancing plenum for diffusers is suitable for both supply and exhaust air.

By connecting diffusers to a balancing plenum in the distribution ductwork, their performance can be improved significantly. It also attenuates noise from the ductwork.

- Ensures proper function of ceiling diffusers

- Enables adjusting of the airflow with adjustment module for supply or exhaust air

The Halton Pop PDI is designed in accordance with the core values of Halton to meet the following requirements:

- Sustainable production with reduced waste and production close to markets

- Excellent performance in terms of airflow range and flexibility

- Comfortable indoor environmental conditions through silent operation

Overview

The Halton Pop PDI balancing plenum for diffusers is suitable for both supply and exhaust air. By connecting diffusers to a balancing plenum in the distribution ductwork, their performance can be improved significantly. It also attenuates noise from the ductwork.

Application area

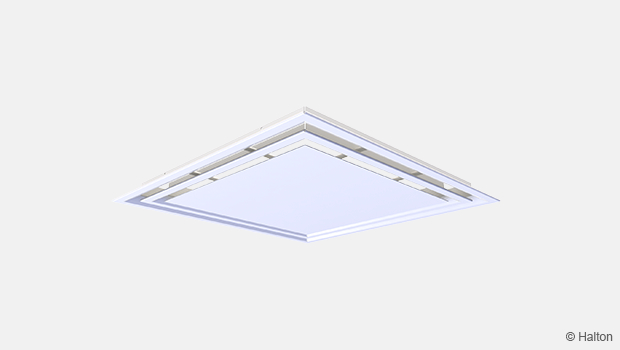

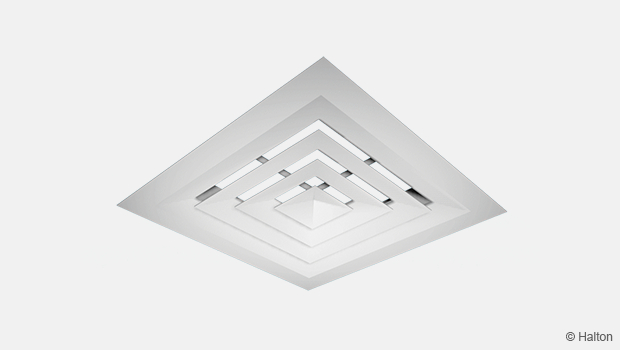

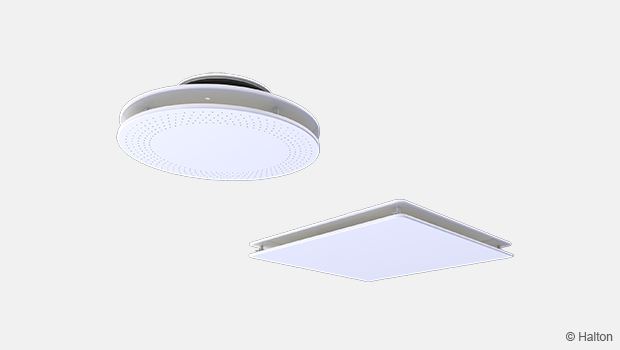

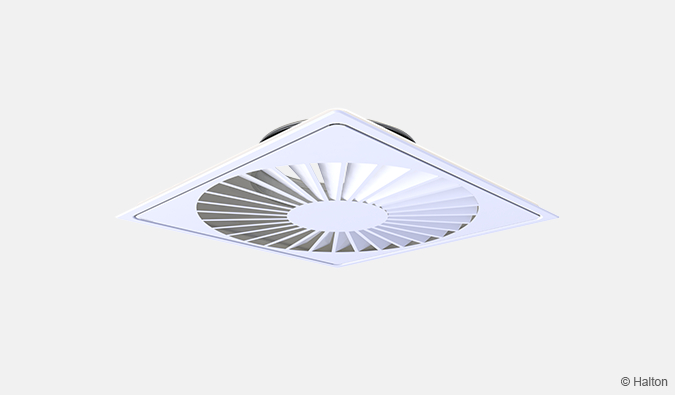

- To be used together with a ceiling diffuser, e.g. Halton Jaz JMC, Halton Jaz JSC, Halton Jaz JDA or Halton TRB.

Key features

- Ensures proper function of ceiling diffusers

- Allows adjusting the airflow with adjustment module for supply or exhaust air (MSM or MEM)

- Makes it easier to connect the diffuser to a ductwork

- Attenuates sound effectively

- Access for ductwork cleaning

Operating principal

Fig. 1. Operating principle of Halton Pop PDI

Halton Pop PDI balancing plenum can be used either supply or exhaust air unit. A range of diffusers can be connected to the distribution ductwork using the plenum, which improves their functional characteristics considerably.

It equalises the airflow by reducing the flow velocity and spreads the air evenly into the diffuser ensuring proper function. Also, the balancing plenum attenuates the duct noise.

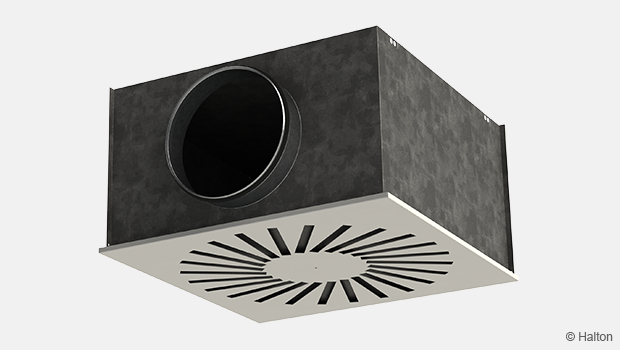

Structure and materials

| No. | Part | Description |

| 1 | Measurement and adjustment module (MSM or MEM) |

|

| 2 | Attenuation material |

|

| 3 | Duct seal gasket | Polymer |

| 4 | Duct connection spigot | Galvanised steel |

| 5 | Casing | Galvanised steel |

| 6 | Gasket | EPDM rubber |

| 7 | Diffuser connection spigot | Galvanised steel |

</span

Dimensions and weight

Fig.2. Dimensions of Halton Pop PDI plenum

| PDI | ØD [mm] |

ØD1 [mm] |

L [mm] |

W [mm] |

H [mm] |

L1 [mm] |

Weight [kg] |

| 100-100 | 99 | 102 | 308 | 282 | 172 | 168 | 2.7 |

| 100-125 | 99 | 127 | 308 | 282 | 172 | 168 | 2.7 |

| 125-125 | 124 | 127 | 308 | 282 | 172 | 168 | 2.8 |

| 125-160 | 124 | 162 | 308 | 282 | 172 | 168 | 2.7 |

| 160-160 | 159 | 162 | 458 | 358 | 239 | 280 | 5.0 |

| 160-200 | 159 | 202 | 458 | 358 | 239 | 280 | 4.9 |

| 200-200 | 199 | 202 | 458 | 358 | 239 | 280 | 5.2 |

| 200-250 | 199 | 252 | 458 | 358 | 239 | 280 | 4.9 |

| 250-250 | 249 | 252 | 520 | 480 | 359 | 280 | 8.2 |

| 250-315 | 249 | 317 | 520 | 480 | 359 | 280 | 8.0 |

| 315-315 | 314 | 402 | 520 | 480 | 359 | 280 | 8.2 |

| 315-400 | 314 | 317 | 520 | 480 | 359 | 280 | 8.0 |

Specification

Balancing plenum for ceiling diffusers, fulfilling the following requirements:

Structure

- Plenum has a removable adjustment module MSM for supply or MEM for exhaust.

- In supply application, it is possible to measure and adjust the airflow with the MSM module.

- Diffuser connection spigot can be turned outside or inside position to help installation work.

- Inlet duct diameter 100, 125, 160, 200, 250 or 315 mm.

- Diffuser connection diameter 100, 125, 160, 200, 250, 315 or 400 mm.

Materials

- Plenum manufactured from galvanised steel.

- Connection spigot manufactured from galvanised steel.

- Connection spigot equipped with fixed gasket.

- Attenuation material made of polyester fibre or mineral wool.

- No harmful materials are released from the attenuation material.

Packaging

- The product is packed on a wooden pallet.

Installation

Fig. 3. Installation of Halton Pop PDI from the top

Fig. 4. Installation of Halton Pop PDI from the sides

Halton Pop PDI plenum can be installed using two strips or with M8 drop rods (not included into delivery). There are three possible fixing points in the plenum, shown in Fig. 3. and 4.

The plenum is connected to the distribution ductwork with a spigot equipped with an integrated gasket.

The diffuser connection spigot is turnable, which allows to connect the diffuser in two different ways:

- Connection spigot positioned outwards (as in Fig. 4.)

- Connection spigot positioned inwards, which reduces the height of the diffuser-plenum combination.

The connection spigot is detached by loosening the bracket screws, after which it can be turned to another position.

Commissioning

Fig. 5. Adjustment of airflow

The supply airflow rate is determined by using the measurement and adjustment module MSM. In case of exhaust air, use of adjustment module MEM is recommended. It is not possible to measure exhaust airflow rate with adjustment module MEM.

Pass the tubes and control spindle through the diffuser and close the front panel (if applicable). Measure the differential pressure with a manometer. The flow rate is calculated using the formula below:

![]()

where

- qv Airflow rate [l/s] or [m3/h]

- ∆pm Measured pressure [Pa]

- k The k factor (see the table below)

Adjust the airflow rate by rotating the control spindle until the desired airflow rate (pressure difference) is achieved.

Set the tubes and spindle back into the plenum. Damper position can be locked with a knurled head screw of the adjuster.

| Duct connection (PDI) | k factor for MSM adjuster, opening > 0, [l/s] | |

| > 8D | Min. 3D | |

| 100 | 5.7 | 7.5 |

| 125 | 9.6 | 12.6 |

| 160 | 16.4 | 21.9 |

| 200 | 26.3 | 31.0 |

| 250 | 47.1 | 51.5 |

| 315 | 78.8 | – |

| Duct connection (PDI) | k factor for MSM adjuster, opening > 0, [m3/h] | |

| > 8D | Min. 3D | |

| 100 | 20.6 | 27.0 |

| 125 | 34.4 | 45.4 |

| 160 | 59.0 | 78.8 |

| 200 | 94.8 | 111.6 |

| 250 | 169.5 | 185.4 |

| 315 | 283.6 | – |

Maintenance

Open or detach the diffuser. Detach the measurement and adjustment module by pulling gently from the casing (not from the control spindle or measurement tubes). Wipe the parts with a damp cloth, instead of immersing in water.

The measurement and adjustment module is remounted by pushing the body until it meets the stopper.

The sound attenuation material within the plenum can also be removed, to enable cleaning of the inner side of the plenum. Close or replace the diffuser after cleaning.

Order code

PDI/M-D-E; AC-ZT

| Main options | |

| M = Model | |

| S | Supply (MSM adjuster) |

| E | Exhaust (MEM adjuster) |

| N | No adjustment module |

| D = Plenum duct connection size [mm] | 100, 125, 160, 200, 250, 315 |

| E = Diffuser connection size [mm] | 100, 125, 160, 200, 250, 315, 400 |

| Other options and accessories | |

| AT = Sound attenuation material | |

| P | Polyester fibre |

| W | Mineral wool |

| NA | Not assigned |

| ZT = Tailored product | |

| N | No |

| Y | Yes (ETO) |

Order code example

PDI/S-125-160; AT=P, ZT=N

Downloads

-

Halton Pop PDI – Plenum for diffusers

Data

en

-

Halton Pop PDI – Liitäntälaatikko hajottajille

Data

fi

-

Halton Pop PDI – Plénum pour diffuseurs

Data

fr

-

Halton Pop PDI – Anslutningslåda för spridare

Data

se

-

Halton Pop PDI – Fiche technique

Data

Français (fr) -

Halton Pop PDI – Technical description

Data

English (en) -

Halton Pop PDI – Tekninen kuvaus

Data

Suomi (fi) -

Halton Pop PDI – Teknisk beskrivning

Data

Svenska (sv) -

Halton Supply Air Diffusers brochure

Data

English (en) -

Halton tuloilmahajottajat – esite

Data

Suomi (fi) -

Halton Tilluftsspridare broschyr

Data

Swedish (sv)

"*" indicates required fields