Creating the optimal environment for the sterilisation department

The sterilisation room plays a crucial role in the organization of a hospital, both in terms of the safety of professionals and patients and for the work of personnel.

The typical challenges

The main challenge of sterilisation department spaces is effectively separating the contaminated and clean areas while ensuring a perfect workflow for proper instrument decontamination and protection from recontamination. Additionally, the autoclaves and washing machines produce a lot of steam and heat, so the ventilation system should be able to control and take care of humidity and heat loads.

Do you have a challenge that requires a solution?

Contact us. Let’s see whether we have a ready-made solution for you or can create one together.

Why choose Halton?

Halton Vita Steri is a solution dedicated specifically to sterilisation departments. The solution provides pressure control between clean and unclean areas, protecting the medical equipment sterilisation process. Reliable controllers and sensors ensure the correct pressure cascade to prevent recontamination.

Reliable and hygienic components

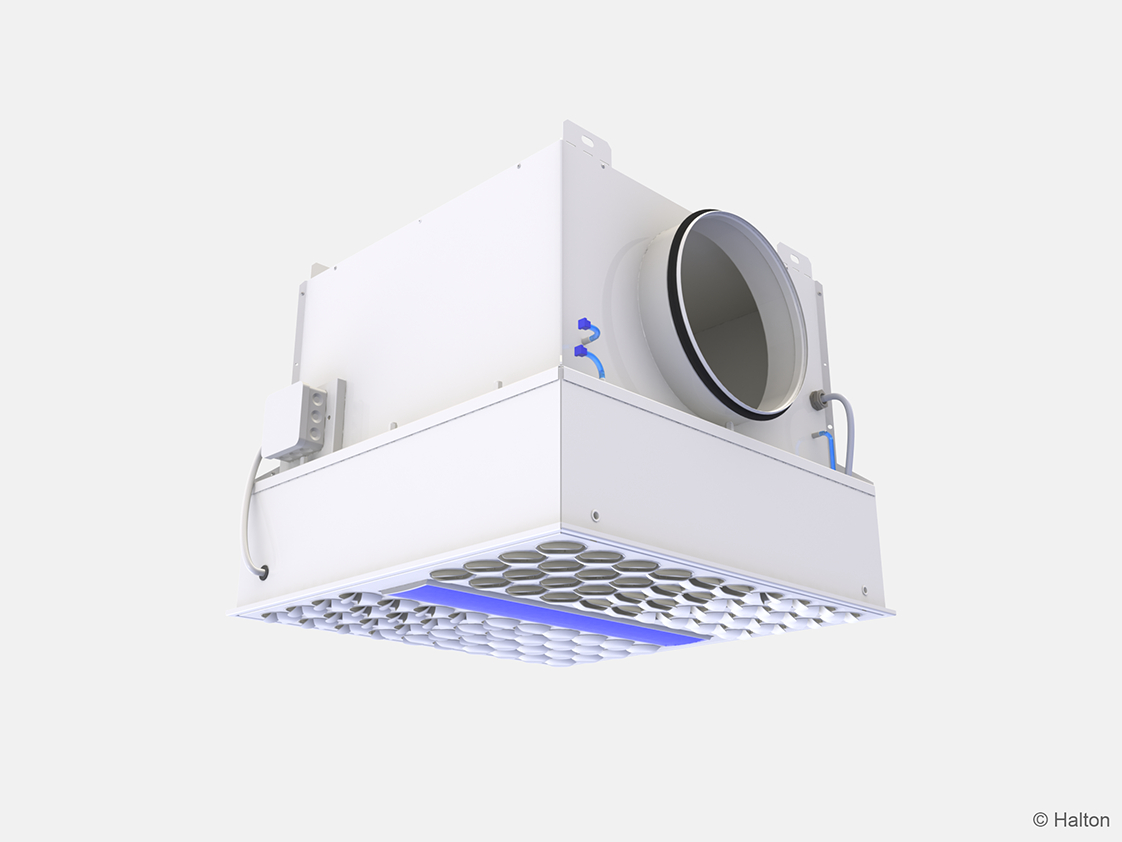

Reliable and hygienic diffusers with HEPA filters in clean and sterile areas ensure a high level of cleanliness of supply air. Thanks to adjustable nozzles, Halton can adjust the airflow pattern to the conditions and layout of each room.

Halton Vita HEPA diffusers are covered in antibacterial paint and are easy to clean, validate and maintain.

To take care of local humidity and heat loads in the space Halton Vita Steri solution includes the extraction canopy manufactured according to USPHS guidelines to capture and remove steam and heat produced in an autoclave and washing machine.

Disinfection blue light

The version of the solution featuring the additional blue light in the diffusers can disinfect the spaces during non-working hours, making the workplace even safer.

Halton delivery includes:

- Design support of the system

- HEPA diffusers

- Extraction canopy

- Room panel

- Supervisory panel

- Room pressure control

- Airflow control

- Pressure sensor

- Commissioning

User friendly touch panels and monitoring system

Thanks to the user-friendly touch panels the users can monitor and control the conditions easily. The supervisory panel gives an overview of the conditions of each room.

Halton Vita Steri solution includes a monitoring system that takes care of follow-up, logging and reporting of operational conditions.

Information can be reviewed remotely from Halton Connect, a cloud-based system that allows 24/7 access to Halton’s solutions.

ECO mode

When the work is done and staff are leaving the space, the system switches to ECO mode, which maintains the pressure and environmental conditions while simultaneously saving energy.

The airflow goes to ECO mode but the pressure control continues controlling as set. The normal mode can be controlled using time control, occupancy sensor or occupancy button.

Contact us!

Our team looks forward to hearing from you. Please give us a call, send us an e-mail, or fill in the form. We’ll be in touch with you shortly.

For inquiries, requests for quotations or ask our specialist. We are here for you.

[contacts]

Contact form

"*" indicates required fields

Operating room solution

Hygienic and comfortable environments for patients, doctors, and nurses

Read more

Patient Room solution

Halton’s Vita Patient Room HVAC Solutions are engineered to provide precision airflow, optimal comfort, and reliable infection control in today’s healthcare environments.

Read more

Isolation room solution

Safe, controlled and comfortable environments for patients and hospital professionals. Flexible solution where you can choose the isolation ventilation solution according to your need.

Read more

Gas and smoke extraction solution

Halton Vita Extract provides a healthy working environment by removing hazardous gases and smoke directly from the source.

Read more

Sterilisation room solution

Safe, controlled and comfortable environments for sterilisation departments.

Read more

Decontamination solution

High-capacity unit can decontaminate large spaces efficiently due to high airflow, well-designed air distribution and concentration surveillance

Read more

Mobile ventilation solution for small operations

Halton Vita Cell Patient upgrades the hygiene of your operations by providing ultra-clean air to the most critical area, the wound area.

Read more

Medical Instrument table ventilation

Halton Vita Cell Instrument delivers air through a laminasor, guaranteeing a stable, horizontal, low-turbulence, and directed airflow over the medical instrument table.

Read more

Mobile clean air ventilation for a room

Halton Vita Cell Room Solution is designed for medical operations and other medical environments to provide temporarily upgraded room hygiene.

Read more

Cafeteria kitchen ventilation

At a smaller scale as the central kitchens, the cafeterias (canteens) for hospitals face the same challenge. Halton's ventilation solutions directly contribute reducing the part of the energy and maintenance in the meal cost with the highest hygiene level.

Read more

Central kitchen ventilation

Health and education sectors are one of the biggest catering segment with ever-increasing quality demands and financial constraints. Halton's ventilation solutions contribute achieving this challenge.

Read more

Free download

Free download