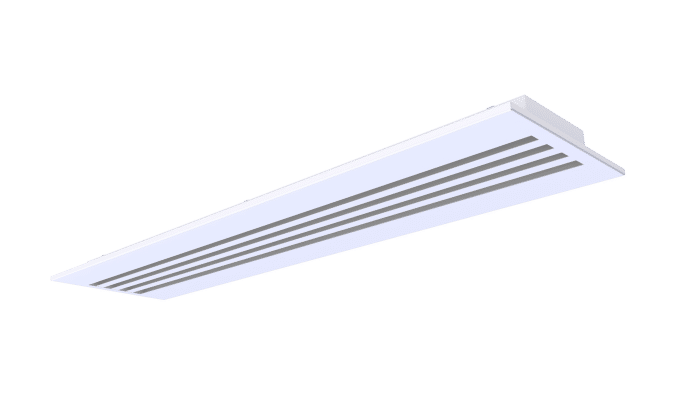

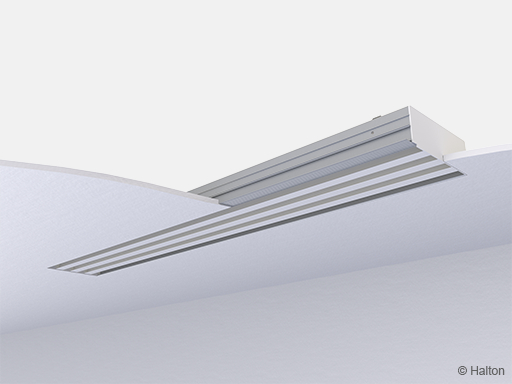

Product / SLL

Overview

- Horizontal or vertical plane jet air supply

- Suitable for supply, exhaust and exhaust with filter

- Special profile diffuser blade creates a Coanda effect which enables wide range of airflow rates

- Supply in one or two directions

- Ceiling or wall installation, suitable also for continuous “wall to wall” installations

- Adjustable throw pattern, flexibility of orientation with different configurations

- Detachable diffuser allows cleaning of the terminal unit and ductwork

Models

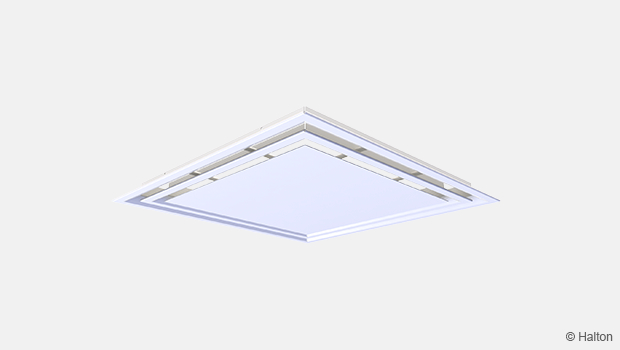

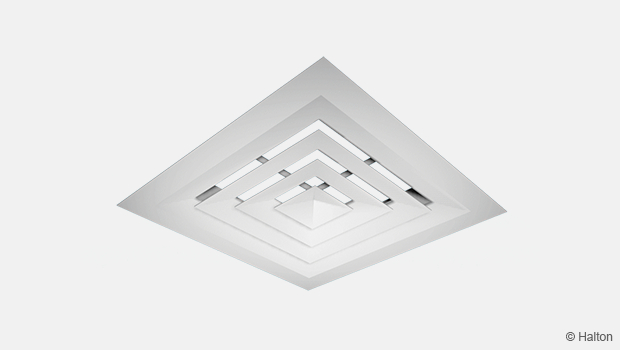

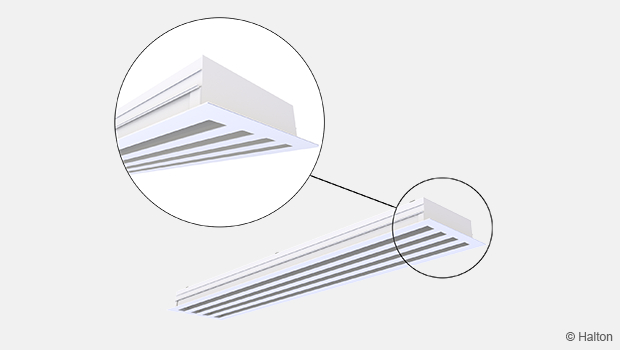

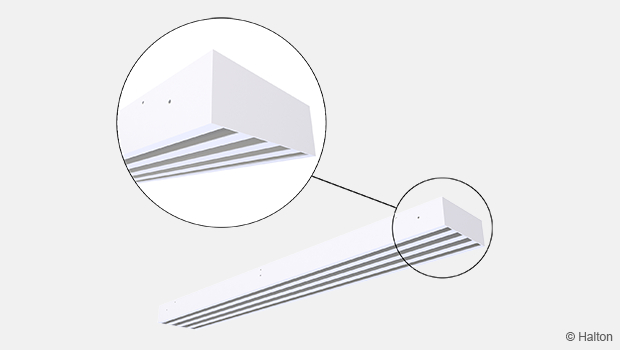

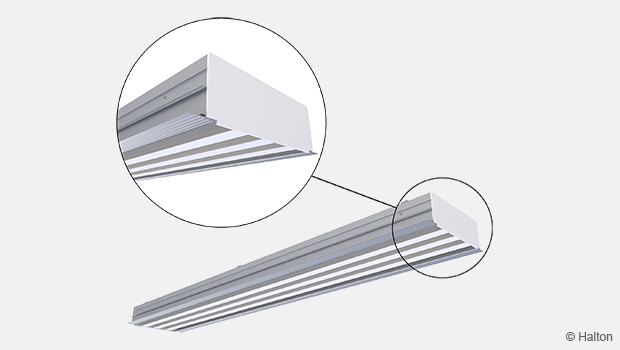

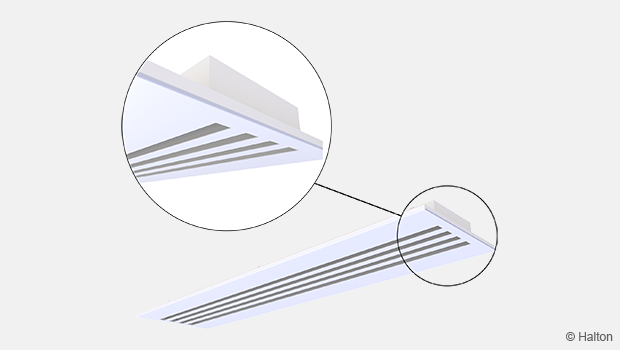

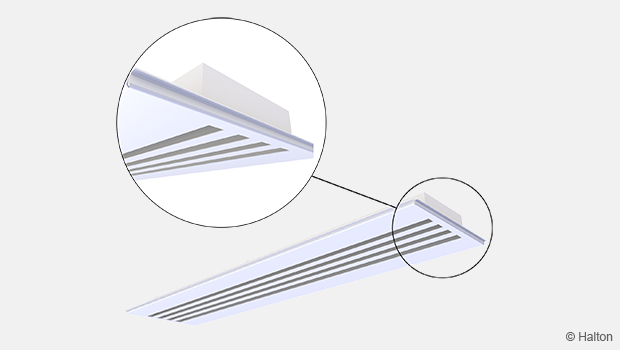

- Frame models: Standard, Cubus and Hidden

- Front plate options: T-Bar and Fineline

Accessories

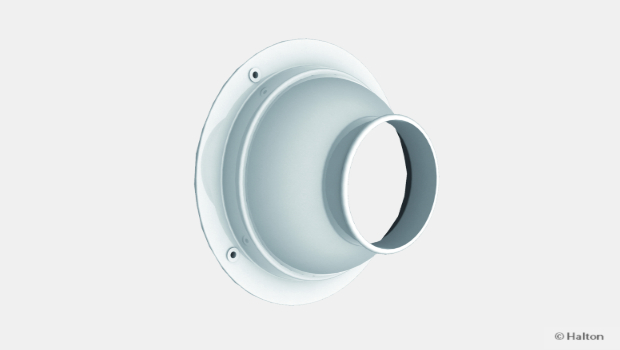

- Plenum with a circular duct connection(s) D160…250mm with rubber gasket

- Plenum options with measurement and adjustment functions

- Sound attenuation for plenum

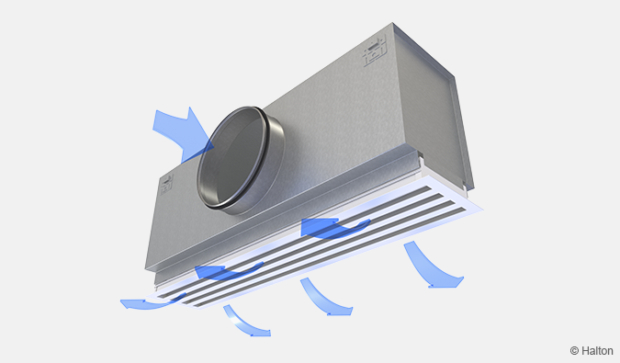

Operating principle

Supply air is supplied through the linear slots of the diffuser, either horizontally along the ceiling surface or vertically into the occupied zone.

For wall installation, the plane jet air is supplied horizontally or directed to the ceiling increasing the throw length.

For exhaust application, the diffuser is delivered without flow control vanes.

Features and options

| Accessory | Code | Description |

| Plenum | PLL | Plenum for duct connection (with or without attenuation material) |

| Plenum | PLD | Plenum for duct connection (without attenuation material) |

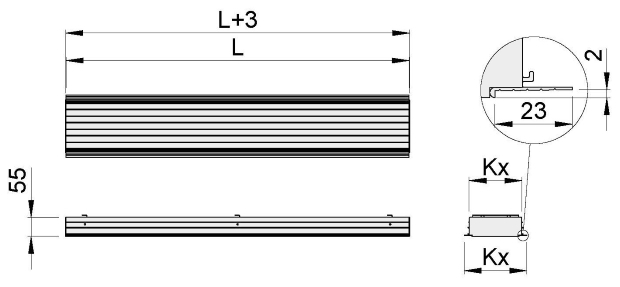

| End caps | N1 | Width = 23 mm (2 pcs) |

| E1 | Width = 12.5 mm (2 pcs) | |

| O1 | Width = 23 mm (1 pc) | |

| O2 | Width = 12.5 mm (1 pc) | |

| O4 | Flat (Cubus) | |

| Installation brackets | – | For installation of the diffuser with a PLL or PLD plenum |

| Staff brackets | – | For installation of the diffuser without plenum |

Special end caps are available for modular ceilings. Please contact sales.

Note: When the Halton PLD is equipped with a filter, then rivets or screws must be used to fix the diffuser to the plenum.

Structure and materials

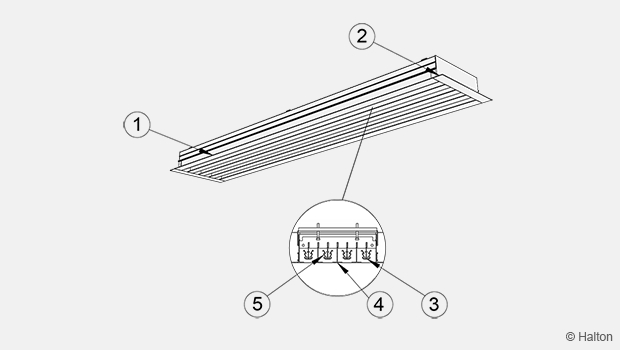

| No | Note | Material | Finishing | Note |

| 1 | Outer frame | Aluminium | Mill finished, Epoxy-painted: White (RAL 9003/30% gloss) |

Special colours available. Epoxy/polyester painted as option. |

| 2 | End caps | Aluminium | Mill finished, Epoxy-painted: White (RAL 9003/30% gloss) |

Special colours available. Epoxy/polyester painted as option. |

| 3 | Inner vanes | Aluminium | Mill finished, Epoxy-painted: White (RAL 9003/30% gloss) |

Special colours available. Epoxy/polyester painted as option. |

| 4 | T profiles | Aluminium | Mill finished, Epoxy-painted: White (RAL 9003/30% gloss) |

Special colours available. Epoxy/polyester painted as option. |

| 5 | Flow deflection vanes (for supply application) |

Aluminium | Mill finished | Special colours available. Epoxy/polyester painted as option. |

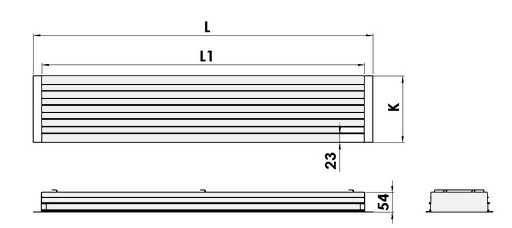

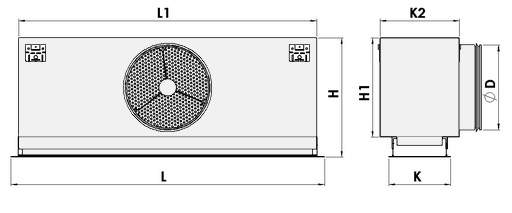

Dimensions

Halton SLL, model with standard frame (FT=S)

The maximum active length of one piece is 2000 mm. The minimum is 372 mm. Continuous diffusers with modular design are also available for installation lengths greater than 2000 mm.

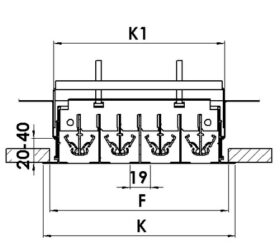

Halton SLL + Halton PLL

Halton SLL, model with standard frame (FT=S)

Standard dimensions of the Halton SLL + Halton PLL unit with standard end caps are presented in the table below.

The number of spigots shown in the table below is Halton’s recommendation. On request other amounts of spigots and sizes are available. Please contact your sales.

| Active length | Number of slots | F | L | L1 | H | H1 | K | K1 | K2 | ØD |

| 572 | 1 | 54 | 618 | 572 | 255..275 | 200 | 67 | 47 | 117 | 1×160 |

| 872 | 1 | 54 | 918 | 872 | 255..275 | 200 | 67 | 47 | 117 | 1×160 |

| 1172 | 1 | 54 | 1218 | 1172 | 255..275 | 200 | 67 | 47 | 117 | 1×160 |

| 1472 | 1 | 54 | 1518 | 1472 | 255..275 | 200 | 67 | 47 | 117 | 2×160 |

| 1772 | 1 | 54 | 1818 | 1772 | 255..275 | 200 | 67 | 47 | 117 | 2×160 |

| 572 | 2 | 92 | 618 | 572 | 295..315 | 240 | 105 | 85 | 155 | 1×200 |

| 872 | 2 | 92 | 918 | 872 | 295..315 | 240 | 105 | 85 | 155 | 1×200 |

| 1172 | 2 | 92 | 1218 | 1172 | 295..315 | 240 | 105 | 85 | 155 | 1×200 |

| 1472 | 2 | 92 | 1518 | 1472 | 295..315 | 240 | 105 | 85 | 155 | 2×200 |

| 1772 | 2 | 92 | 1818 | 1772 | 295..315 | 240 | 105 | 85 | 155 | 2×200 |

| 572 | 3 | 130 | 618 | 572 | 295..315 | 240 | 143 | 123 | 193 | 1×200 |

| 872 | 3 | 130 | 918 | 872 | 295..315 | 240 | 143 | 123 | 193 | 1×200 |

| 1172 | 3 | 130 | 1218 | 1172 | 295..315 | 240 | 143 | 123 | 193 | 1×200 |

| 1472 | 3 | 130 | 1518 | 1472 | 295..315 | 240 | 143 | 123 | 193 | 2×200 |

| 1772 | 3 | 130 | 1818 | 1772 | 295..315 | 240 | 143 | 123 | 193 | 2×200 |

| 572 | 4 | 168 | 618 | 572 | 345..365 | 290 | 181 | 161 | 231 | 1×250 |

| 872 | 4 | 168 | 918 | 872 | 345..365 | 290 | 181 | 161 | 231 | 1×250 |

| 1172 | 4 | 168 | 1218 | 1172 | 345..365 | 290 | 181 | 161 | 231 | 1×250 |

| 1472 | 4 | 168 | 1518 | 1472 | 345..365 | 290 | 181 | 161 | 231 | 2×250 |

| 1772 | 4 | 168 | 1818 | 1772 | 345..365 | 290 | 181 | 161 | 231 | 2×250 |

| 572 | 5 | 206 | 618 | 572 | 345..365 | 290 | 219 | 199 | 269 | 1×250 |

| 872 | 5 | 206 | 918 | 872 | 345..365 | 290 | 219 | 199 | 269 | 1×250 |

| 1172 | 5 | 206 | 1218 | 1172 | 345..365 | 290 | 219 | 199 | 269 | 1×250 |

| 1472 | 5 | 206 | 1518 | 1472 | 345..365 | 290 | 219 | 199 | 269 | 2×250 |

| 1772 | 5 | 206 | 1818 | 1772 | 345..365 | 290 | 219 | 199 | 269 | 2×250 |

| 572 | 6 | 244 | 618 | 572 | 345..365 | 290 | 257 | 237 | 277 | 1×250 |

| 872 | 6 | 244 | 918 | 872 | 345..365 | 290 | 257 | 237 | 277 | 1×250 |

| 1172 | 6 | 244 | 1218 | 1172 | 345..365 | 290 | 257 | 237 | 277 | 1×250 |

| 1472 | 6 | 244 | 1518 | 1472 | 345..365 | 290 | 257 | 237 | 277 | 2×250 |

| 1772 | 6 | 244 | 1818 | 1772 | 345..365 | 290 | 257 | 237 | 277 | 2×250 |

Installation hole in the ceiling = F x (L1+10)

Frame type: Cubus (FT=C)

| Feature | Number of slots | K3 |

| Active length (L) |

1 | 40 |

| 2 | 78 | |

| 3 | 116 | |

| 4 | 154 | |

| 5 | 192 | |

| 6 | 230 |

Frame type: Hidden (FT=H)

| Feature | Number of slots | Kx |

| Active length (L) |

1 | 68 |

| 2 | 106 | |

| 3 | 144 | |

| 4 | 182 | |

| 5 | 220 | |

| 6 | 258 |

Front plate: T bar ceiling (FP=TC1, TC2)

| Front plate | L2 | Active length (L) | Number of slots | K4 |

| TC1 | 1195 | 572, 872 or 1150 | 1 | 39 |

| 2 | 77 | |||

| 3 | 115 | |||

| 4 | 153 | |||

| 5 | 191 | |||

| 6 | 229 | |||

| TC2 | 1345 | 572, 872, 1150, 1172, 1250 or 1300 | 1 | 39 |

| 2 | 77 | |||

| 3 | 115 | |||

| 4 | 153 | |||

| 5 | 191 | |||

| 6 | 229 |

Front plate: Fineline ceiling (FP=FC1, FC2)

| Front plate | L2 | Active length (L) | Number of slots | K4 |

| FC1 | 1183 | 572, 872 or 1150 | 1 | 39 |

| 2 | 77 | |||

| 3 | 115 | |||

| 4 | 153 | |||

| 5 | 191 | |||

| 6 | 229 | |||

| FC2 | 1333 | 572, 872, 1150, 1172, 1250 or 1300 | 1 | 39 |

| 2 | 77 | |||

| 3 | 115 | |||

| 4 | 153 | |||

| 5 | 191 | |||

| 6 | 229 |

Specification

Halton-brand ceiling diffuser, type Halton SLL, with one to six slots, suitable for variable air flow.

Function

- Excellent Coanda effect at a wide range of airflow rates.

- Each air pattern adjustment section comprises two flow deflection vanes.

- The supply air pattern is directional, controlled by adjusting the flow deflection vanes without altering the appearance of the diffuser.

Materials

- The linear slot diffuser has an extruded aluminum outer frame, flow deflection vanes, and T-profiles, and is polyester-painted white (RAL 9003), with other options available.

Structure

- The diffuser is connected to the ductwork using a plenum with mineral wool as sound attenuation material.

- The removable linear slot diffuser is mounted into the plenum with invisible screws.

- The plenum comprises an airflow measurement and adjustment module.

The linear diffuser is removable in order to provide access to the measurement and adjustment module in the plenum. - Flow deflection vanes and T-profiles are easily removable for access to the plenum.

Product models

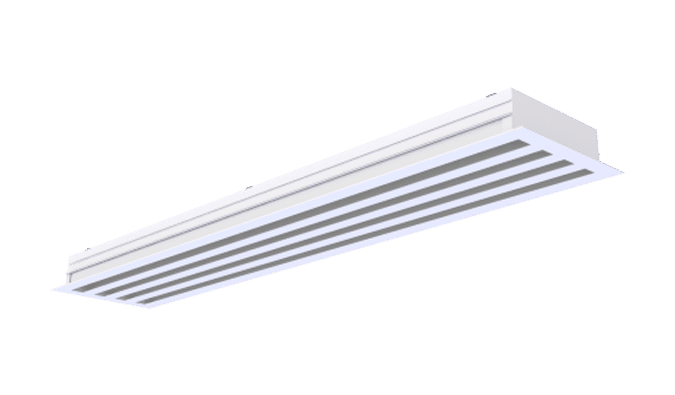

Frame model: Standard (FT=S)

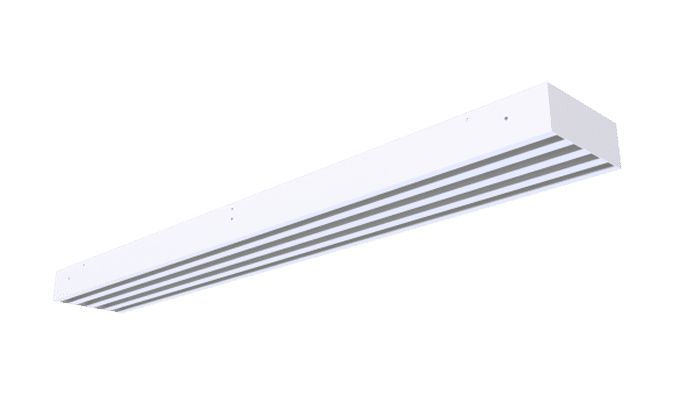

Frame model: Cubus (FT=C)

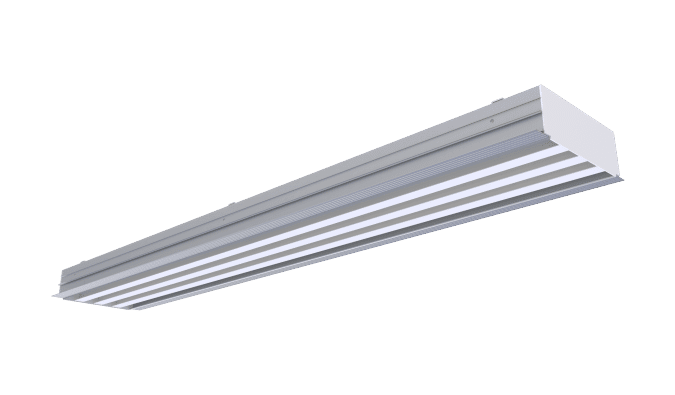

Frame model: Hidden (FT=H)

Front plate: T bar ceiling (FP=TC1 or TC2)

Front plate: Fineline ceiling (FP=FC1 or FC2)

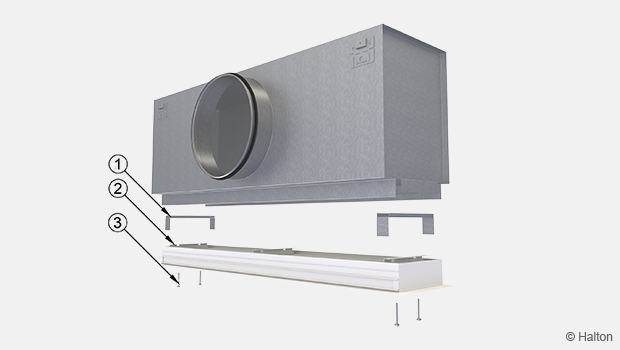

Installation

| No. | Part |

| 1 | Mounting bracket |

| 2 | Transversal bar |

| 3 | Screw |

The Halton SLL linear slot diffuser is connected directly to the Halton PLL or Halton PLD plenum.

The plenum is installed into the suspended ceiling with M8 drop rods (not included in the delivery) and connected to the ductwork.

- Remove the T-profiles of the Halton SLL by pulling them gently, in order to access the transversal bars located behind the profiles.

- Fit the installation brackets into the grooves of the plenum and secure with the screws supplied with the unit.

- Put screws into the holes of the transversal bars. Screw on until the diffuser is flush to the ceiling.

- Replace the T-profiles.

The unit can be installed without plenum using the staff brackets. Those pieces are available as accessory (2 by slad or by linear meter).

Note: When the Halton PLD is equipped with a filter, then rivets or screws must be used to fix the diffuser to the plenum.

String course mounting

The maximum length is 2000 mm. When the length exceeds 2000 mm, it is necessary to place several pieces side by side. Some alignment guides are provided to make the the mounting easier.

Installation of Hidden model (FT = H)

The linear slot diffuser with a hidden frame incorporates the same internal components as a standard slotted diffuser, ensuring identical technical performance. The distinction lies in its specially designed aluminium frame and end caps, featuring a tapered-edge profile that allows the frame to be seamlessly integrated into the ceiling. Once installed, the frame can be plastered over to achieve a fully concealed/hidden appearance.

The removable end caps clip onto the diffuser for easy on‑site access, and the alignment strip is included as standard. The diffuser can also be connected to a conventional plenum box. As the internal assembly matches the standard model, all airflow and acoustic characteristics remain unchanged.

Commissioning

The air pattern can be changed through 180° by adjusting the flow deflection vanes with a screwdriver. Each deflection vane section can be individually adjusted without removing the T-profiles providing flexibility in the supply air pattern orientation.

Diffusers are delivered unadjusted with the flow deflection vanes in the open position.

To aid in adjusting and measuring the airflow rate, it is recommended that the diffuser is connected to a plenum equipped with an MSM.

The supply airflow is determined by measuring the pressure difference with a measurement module.

Measure the differential pressure with a manometer. The airflow rate is calculated according to the following formula:

| ∆pm | Measured pressure [Pa] |

| k | k-factor given as a function of mounting and diameter |

| qv | Airflow rate [l/s] |

The k-factor for installations with different safety distances (distance of other items from the MSM):

| NS | Safety distance | |

| > 6D | min 3D | |

| 160 | 19 | 22 |

| 200 | 49 | 32 |

| 250 | 51 | 51 |

Adjust the airflow rate by rotating the control spindle until the desired setting is achieved.

Lock the damper in position with a screw.

Replace the tubes and spindle in the plenum, and return the linear diffuser to its position.

Maintenance

- Remove the T-profiles.

- Remove the linear diffuser by unscrewing the screws of the transversal bars.

- Clean the parts by wiping with a damp cloth.

- Push the linear diffuser back into place by screwing the transversal bars to the installation brackets.

Option:

With balancing plenum Halton PLD + MSM/MEM or Halton PLL + MSM/MEM

Remove the measurement and adjustment module by gently pulling the shaft (not the control spindle or measurement tubes!).

Wipe the parts with a damp cloth, instead of immersing them in water.

Reassemble the measurement and adjustment module by pushing the shaft back into place until the module meets the stopper.

Push the linear diffuser back into place by screwing the transversal bars to the installation brackets.

Order code

SLL-S-N-L; FP-FT-SE-ST-FI-ID-CO-ZT

| Main options | |

| S = Model | |

| S | Supply |

| E | Exhaust |

| O | Opening front |

| N= Number of slots | 1, 2, 3, 4, 5, 6 |

| L = Active length [mm] | 372, +1, .., 49972 |

| Other options and accessories | |

| FP = Front plate option | |

| NA | Not assigned |

| TC1 | T bar ceiling (1200×300) |

| FC1 | Fineline ceiling (1200×300) |

| TC2 | T bar ceiling (1350×300) |

| FC2 | Fineline ceiling (1350×300) |

| FT = Frame type | |

| S | Standard |

| C | Cubus |

| H | Hidden |

| NA | Not assigned |

| SE = End caps | |

| Y | Yes |

| N | No |

| ST = Type of end caps | |

| N1 | 23.0 mm (2 pcs) |

| E1 | 12.5 mm (2 pcs) |

| O1 | 23.0 mm (1 pc) |

| O2 | 12.5 mm (1 pc) |

| O4 | Flat (Cubus) |

| NA | Not assigned |

| FI = Finishing | |

| PN | Painted |

| MF | Mill finished |

| ID = Diffuser assembled with plenum | |

| N | No |

| Y | Yes |

| CO = Colour | |

| SW | Signal white (RAL 9003) |

| X | Special colour (RAL xxx) |

| N | No painting |

| ZT = Tailored product | |

| N | No |

| Y | Yes (ETO) |

| Sub products | |

| PLL | Plenum |

| PLD | Plenum |

Order code example

SLL-S-4-5200; FP=NA, FT=S, SE=Y, ST=N1, FI=PN, ID=N, CO=SW, ZT=N

Downloads

"*" indicates required fields