Product / CID01

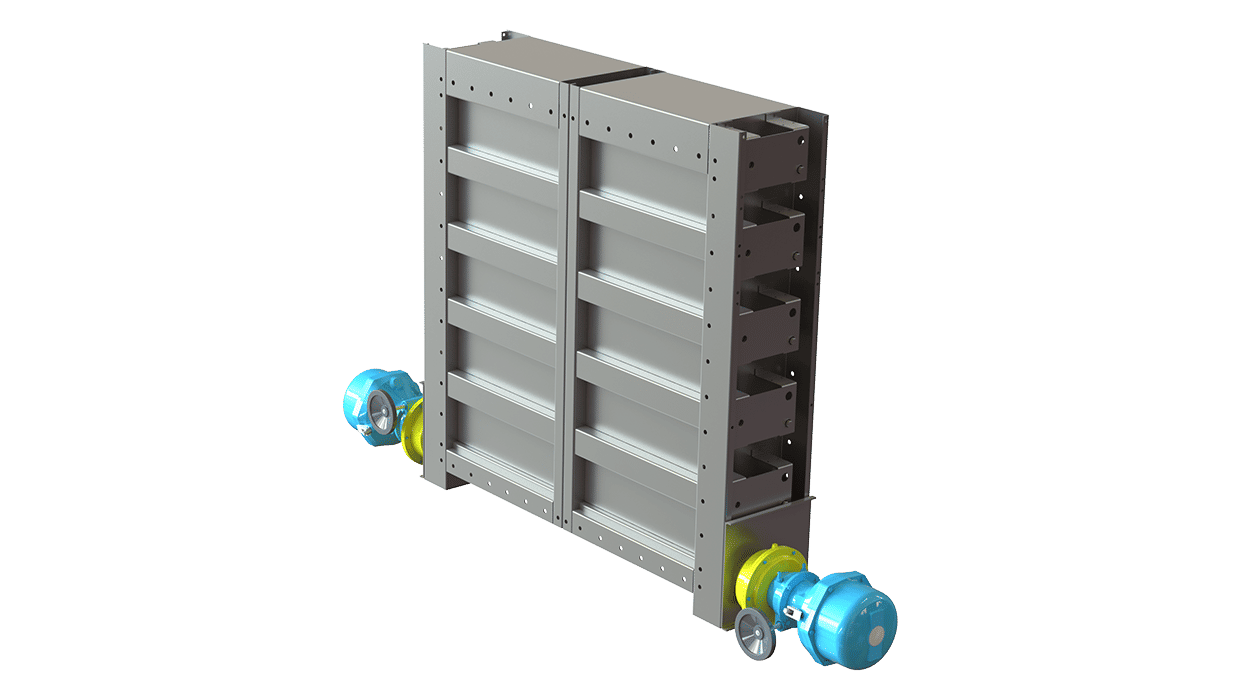

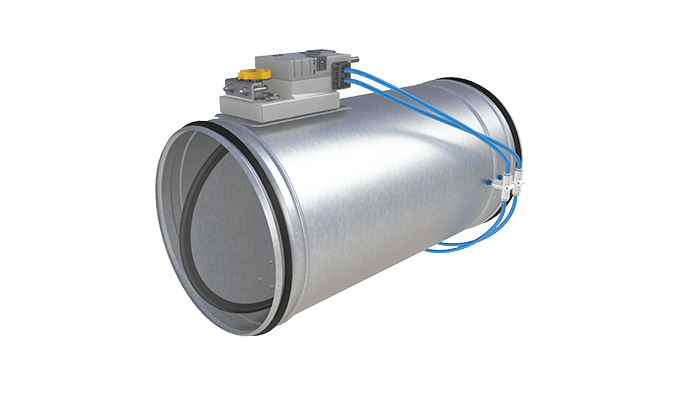

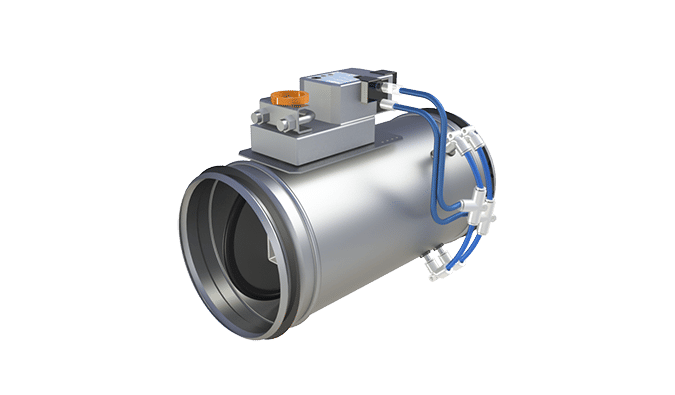

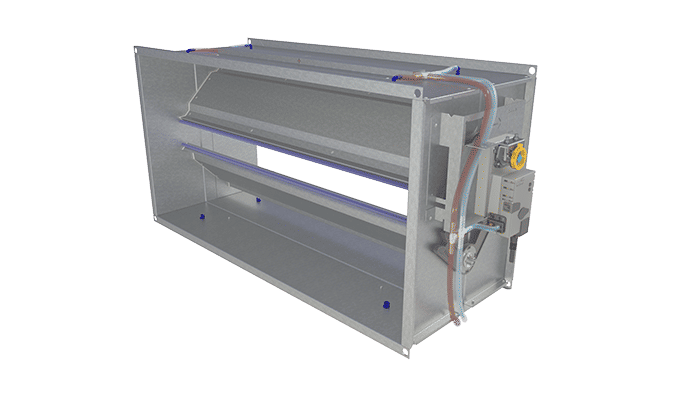

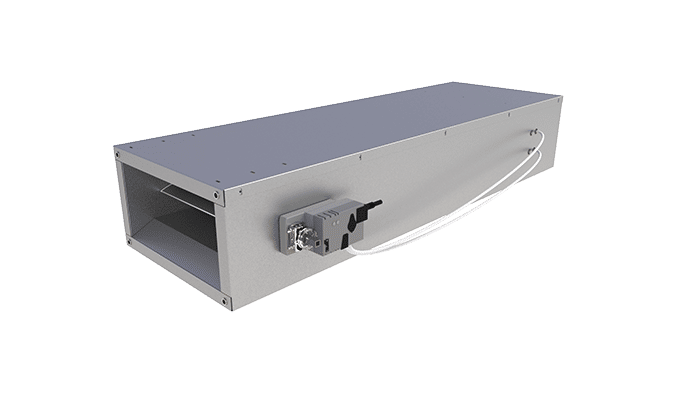

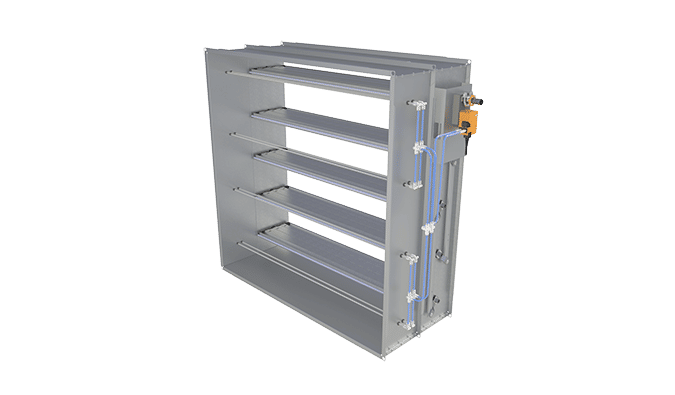

CID-01 – Zero leakage isolation damper

The type CID-01 Isolation Damper has been specifically designed to meet the tightest shut- off requirements of the industrial and nuclear markets, where isolation of ducting for filter replacement or duct inspection is required, without shutting down complete systems.

Overview

- The Safety Function of the Isolation Damper when actuated is to close and control pressure system balancing or recirculation of air. This function may be used in both high or low demand mode applications

- Each damper is tested to ensure there is zero leakage through the blades and casing

- Has been assessed by Sira Certification Service with reference to the CASS methodologies and found to meet the requirements of IEC 61508-2:2010

- Damper has achieved a SIL 2 rating

Specification

The type CID-01 Isolation Damper has been specifically designed to meet the tight shut- off requirements of the industrial and nuclear markets, where isolation of ducting for filter replacement or duct inspection is required, without shutting down complete systems. These versatile dampers can be automatically or manually operated and can be supplied with pre-drilled flanges to ease installation.

The dampers may be installed vertically or horizontally with the air flow in one direction.

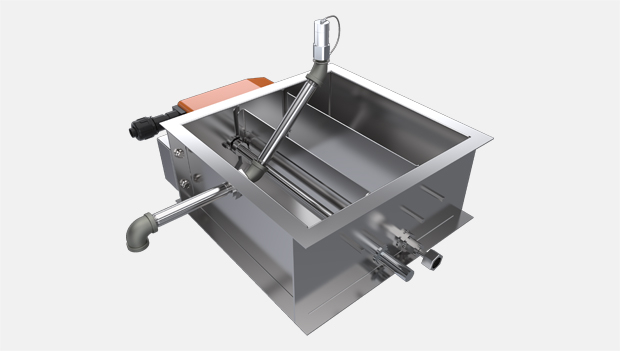

Each complete damper assembly is subjected to a works pressure test of 10,000 Pa for one hour. The upstream end of the damper is sealed during the test and the pressurizing source removed. After one hour the pressure is checked to ensure that it has not dropped taking into consideration any changes in air temperature.

Dimensions

Casing

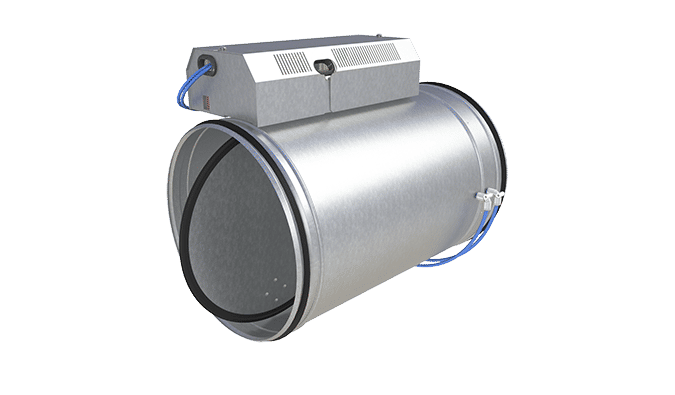

The damper casing is formed from 3.0 mm thick sheet steel into a rigid channel section to ensure proper alignment of blades and shafts. Where circular dampers are required, additional spigot adaptors are used which increase the damper insertion length from 350 to 450 mm.

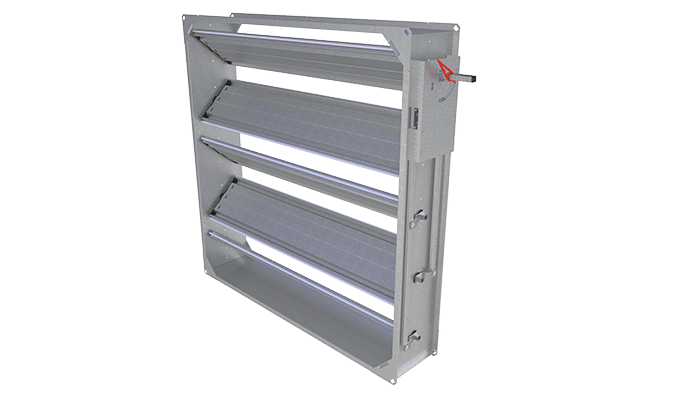

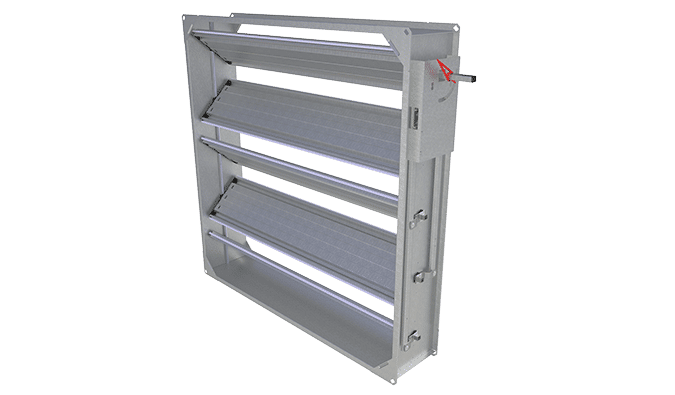

Blades

The blades are a formed single skin of 3.0 mm sheet steel fitted with a closed cell pad that seals against a frame within the damper casing to provide 100% isolation.

Shafts

Continuous shafts Ø 19.05 mm with welded pivoted- blade support at each end.

Linkage

Parallel action linkage consisting of drive levers and bosses connected by flat bar link bars, driven through stainless steel pins. All linkage is contained within the depth of the casing.

Bearings

Phosphor bronze self-lubricated plain ‘Oilite’ bushes fitted into bearing bosses welded to the outside of the casing.

Shaft seals

Lipseal type fitted into each bearing boss.

CID-01 General Drawings

Material and Finishing

| Part | Material | Finishing |

| Case | Steel | Painted or Galvanised |

| Case | Stainless Steel – 1.4307 (304L) Stainless Steel – 1.4404 (316L) |

– |

| Blades | Steel | Galvanised |

| Blades | Stainless Steel – 1.4307 (304L) Stainless Steel – 1.4404 (316L) |

– |

| Shafts | Stainless Steel – 1.4307 (304L) Stainless Steel – 1.4404 (316L) |

– |

| Bearings | Phosphor bronze self-lubricated plain ‘Oilite’ | – |

Product Models and Accessories

- Damper can be supplied with either; Pneumatic Actuator, Electric Actuator, Manual Handwheel

- Earth continuity bosses can be supplied upon request

- Lifting lugs are provided to allow safe lifting of the damper

- Solenoid Valves

- Remote Indication of damper blade position using microswitches

- Local Indication of damper blade position

Other variations to suit clients’ specific requirements are also available. Please contact sales staff for further details

Operation Principle

The Safety Function of the Isolation Damper when actuated is to close and control pressure system balancing or recirculation of air. The damper blades are fitted with a closed cell pad that seals against a frame within the damper casing to provide 100% isolation, allowing for work to be carried out within the duct network or stopping the spread of contaminates. Please note the damper is not bi-directional and air flow must be as shown in the general drawings above.

Weights

Please note the below table gives bare shaft damper weights only at the given square dimensions. Weights for specific sizes are issued on the quotation document.

| Damper size (mm) | Est. weight | ||

| Width/Dia. | Height | Depth | |

| 150 | 150 | 450 | 51 kg |

| 200 | 200 | 350 | 40 kg |

| 250 | 250 | 350 | 43 kg |

| 300 | 300 | 350 | 47 kg |

| 350 | 350 | 350 | 76 kg |

| 400 | 400 | 350 | 80 kg |

| 450 | 450 | 350 | 85 kg |

| 500 | 500 | 350 | 90 kg |

| 550 | 550 | 350 | 95 kg |

| 600 | 600 | 350 | 127 kg |

| 650 | 650 | 350 | 132 kg |

| 700 | 700 | 350 | 138 kg |

| 750 | 750 | 350 | 144 kg |

| 800 | 800 | 350 | 150 kg |

| 850 | 850 | 350 | 185 kg |

| 900 | 900 | 350 | 192 kg |

| 950 | 950 | 350 | 199 kg |

| 1000 | 1000 | 350 | 206 kg |

Installation

Dampers can be duct mounted, floor mounted, roof mounted, or bulkhead mounted depending upon the application.

Downloads

Request for Quotation

"*" indicates required fields