Product / UTT

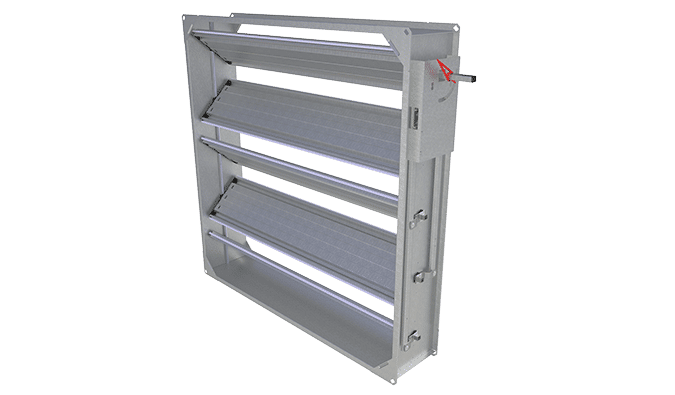

Halton UTT – Multi-blade airflow management damper (CAV)

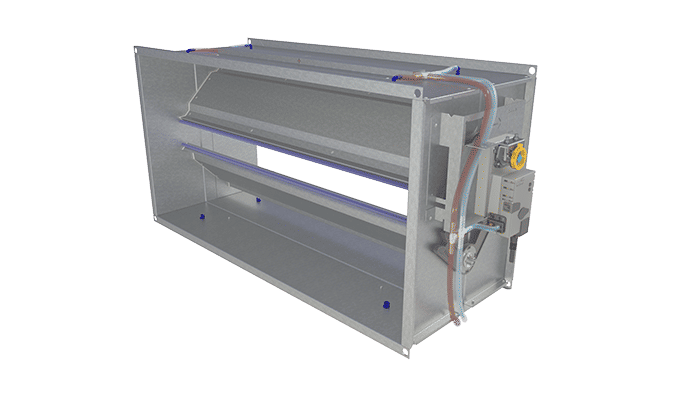

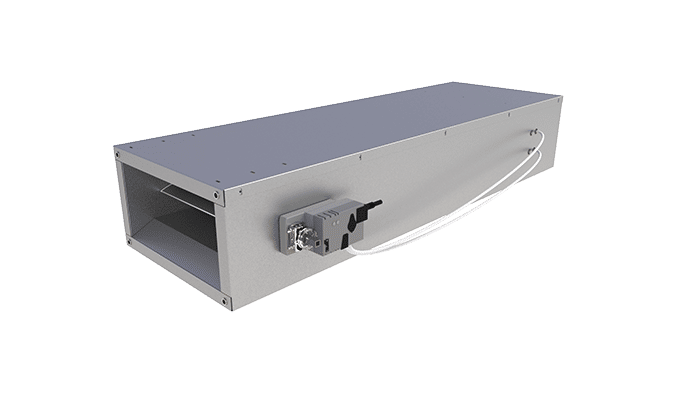

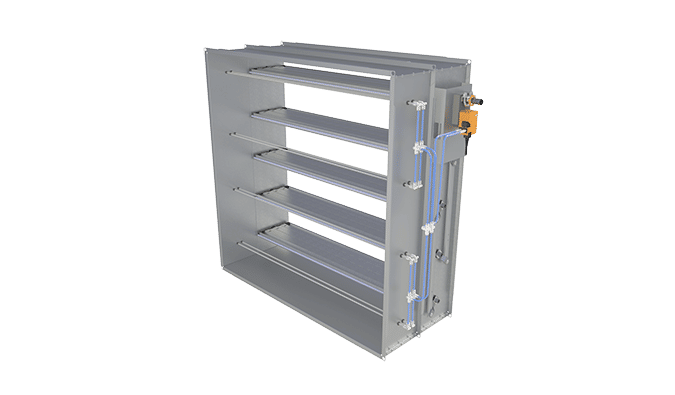

Rectangular tight shut-off and balancing damper available with various modular construction and sizes.

The shut-off class 3 according to EN 1751.

- Shut-off and balancing damper for outdoor air intake and exhaust air with opposed blade design

- Damper blades comprise thermal insulation

Overview

- Shut-off and balancing damper for outdoor air intake and exhaust air with opposed blade design

- Damper blades comprise thermal insulation

- Tightness in closed position fulfills EN 1751 class 3 requirements

- Temperature operation range up to +100°C, optionally up to +200°C

- Galvanised steel design

- Classification of casing leakage EN 1751 class B

Product models and accessories

- Model with stainless steel /acid-proof steel (AISI 316L) design.

- Model with insulated casing

- Model with heat-proof design

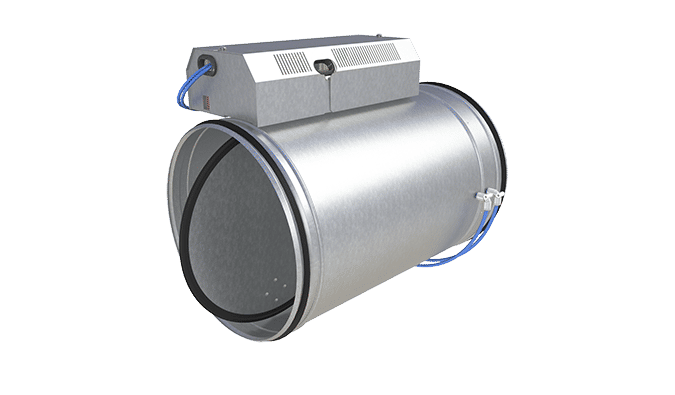

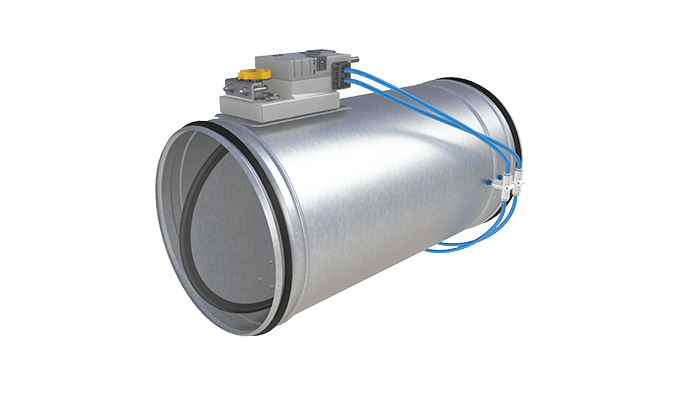

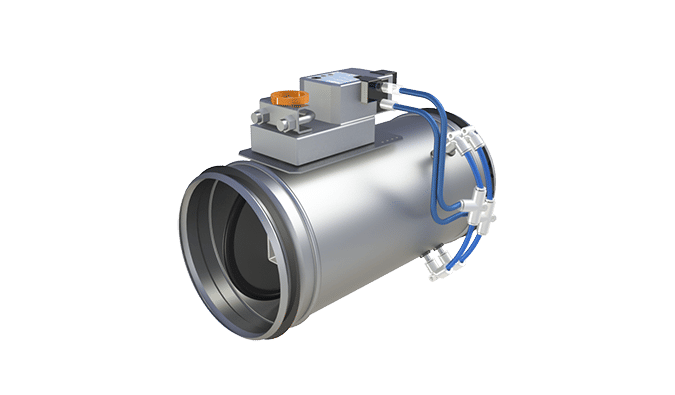

- Circular duct connections

- Several actuator options

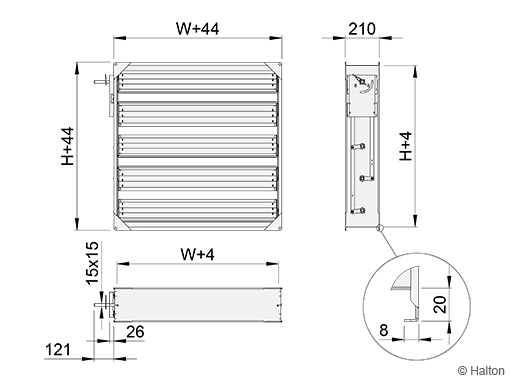

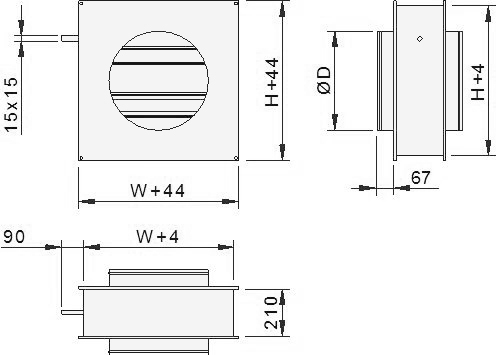

Dimensions and weight

Models with rectangular connections

| W | H |

| 100, 200, …, 2400 | 100, 200, …, 2400 |

Models with circular connections (D1 or D2)

| ØD | W x H |

| 100 | 150×150 |

| 125 | 150×150 |

| 160 | 200×200 |

| 200 | 200×200 |

| 250 | 250×250 |

| 315 | 300×300 |

| 400 | 400×400 |

| 500 | 500×500 |

| 630 | 600×600 |

| 710 | 800×800 |

| 800 | 800×800 |

| 1000 | 1000×1000 |

| 1250 | 1300×1300 |

Weight [kg]

Weight presented without actuator. Basic actuator weight about 1 kg.

| H | W | |||||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | |

| 200 | 3 | 3 | 4 | 5 | 6 | 7 | 7 | 8 | 9 | 9 | 10 | 16 |

| 300 | 4 | 5 | 6 | 7 | 7 | 8 | 9 | 10 | 11 | 11 | 12 | 19 |

| 400 | 5 | 6 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 13 | 20 |

| 500 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 22 |

| 600 | 6 | 7 | 8 | 9 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 24 |

| 700 | 7 | 8 | 9 | 10 | 11 | 13 | 14 | 15 | 16 | 18 | 19 | 26 |

| 800 | 8 | 9 | 10 | 12 | 13 | 14 | 16 | 17 | 18 | 20 | 21 | 28 |

| 900 | 8 | 10 | 11 | 12 | 14 | 15 | 17 | 18 | 20 | 21 | 23 | 30 |

| 1000 | 9 | 11 | 12 | 14 | 15 | 17 | 18 | 20 | 22 | 23 | 25 | 32 |

| 1100 | 10 | 11 | 13 | 15 | 16 | 18 | 20 | 21 | 23 | 25 | 26 | 34 |

| 1200 | 11 | 12 | 14 | 16 | 18 | 19 | 21 | 23 | 25 | 27 | 28 | 36 |

| 1300 | 11 | 13 | 15 | 17 | 19 | 21 | 22 | 24 | 26 | 28 | 30 | 38 |

| 1400 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 40 |

| 1500 | 13 | 15 | 17 | 19 | 21 | 23 | 25 | 27 | 30 | 32 | 34 | 42 |

| 1600 | 14 | 16 | 18 | 20 | 22 | 25 | 27 | 29 | 31 | 34 | 36 | 44 |

| 1700 | 14 | 16 | 19 | 21 | 23 | 26 | 28 | 30 | 33 | 35 | 38 | 46 |

| 1800 | 15 | 17 | 20 | 22 | 25 | 27 | 30 | 32 | 35 | 37 | 40 | 48 |

| 1900 | 16 | 18 | 21 | 23 | 26 | 28 | 31 | 34 | 36 | 39 | 41 | 50 |

| 2000 | 16 | 19 | 22 | 25 | 27 | 30 | 33 | 35 | 38 | 41 | 43 | 52 |

| 2100 | 17 | 20 | 23 | 25 | 28 | 31 | 34 | 37, | 39 | 42 | 45 | 54 |

| 2200 | 18 | 21 | 24 | 27 | 30 | 33 | 36 | 38 | 41 | 44 | 47 | 56 |

| 2300 | 19 | 22 | 25 | 28 | 31 | 34 | 37 | 40 | 43 | 46 | 49 | 58 |

| 2400 | 20 | 23 | 26 | 29 | 32 | 35 | 38 | 42 | 45 | 49 | 51 | 60 |

| H | W | |||||||||||

| 1300 | 1400 | 1500 | 1600 | 1700 | 1800 | 1900 | 2000 | 2100 | 2200 | 2300 | 2400 | |

| 200 | 17 | 17 | 18 | 21 | 21 | 22 | 23 | 25 | 26 | 27 | 27 | 28 |

| 300 | 20 | 20 | 21 | 24 | 25 | 26 | 26 | 29 | 30 | 31 | 32 | 32 |

| 400 | 21 | 22 | 23 | 26 | 27 | 27 | 28 | 31 | 32 | 33 | 34 | 35 |

| 500 | 23 | 24 | 25 | 28 | 29 | 30 | 31 | 34 | 35 | 36 | 37 | 38 |

| 600 | 25 | 26 | 27 | 31 | 32 | 33 | 34 | 37 | 38 | 39 | 40 | 41 |

| 700 | 27 | 28 | 29 | 33 | 34 | 35 | 36 | 40 | 41 | 42 | 43 | 44 |

| 800 | 29 | 31 | 32 | 35 | 37 | 38 | 39 | 43 | 44 | 45 | 47 | 48 |

| 900 | 31 | 33 | 34 | 38 | 39 | 40 | 42 | 45 | 47 | 48 | 50 | 51 |

| 1000 | 34 | 35 | 37 | 40 | 42 | 43 | 45 | 49 | 50 | 52 | 53 | 55 |

| 1100 | 35 | 37 | 39 | 42 | 44 | 46 | 47 | 51 | 53 | 54 | 56 | 58 |

| 1200 | 38 | 40 | 41 | 45 | 47 | 49 | 51 | 54 | 56 | 58 | 60 | 62 |

| 1300 | 40 | 41 | 43 | 47 | 49 | 51 | 53 | 57 | 59 | 61 | 63 | 65 |

| 1400 | 42 | 44 | 46 | 50 | 52 | 54 | 56 | 60 | 62 | 64 | 66 | 68 |

| 1500 | 44 | 46 | 48 | 52 | 54 | 56 | 59 | 63 | 65 | 67 | 69 | 71 |

| 1600 | 46 | 48 | 51 | 55 | 57 | 59 | 62 | 66 | 68 | 70 | 73 | 75 |

| 1700 | 48 | 50 | 53 | 57 | 59 | 62 | 64 | 69 | 71 | 73 | 76 | 78 |

| 1800 | 50 | 53 | 55 | 60 | 62 | 65 | 67 | 72 | 74 | 77 | 79 | 82 |

| 1900 | 52 | 55 | 57 | 62 | 65 | 67 | 70 | 74 | 77 | 79 | 82 | 85 |

| 2000 | 55 | 57 | 60 | 65 | 67 | 70 | 73 | 78 | 80 | 83 | 86 | 88 |

| 2100 | 56 | 59 | 62 | 67 | 70 | 72 | 75 | 80 | 83 | 86 | 89 | 91 |

| 2200 | 59 | 62 | 65 | 70 | 73 | 76 | 78 | 83 | 86 | 89 | 92 | 95 |

| 2300 | 61 | 64 | 67 | 72 | 75 | 78 | 81 | 86 | 89 | 92 | 95 | 98 |

| 2400 | 63 | 66 | 69 | 75 | 78 | 81 | 84 | 89 | 92 | 95 | 99 | 102 |

| ØD | UTT/D1 | UTT/D2 | ØD | UTT/D1 | UTT/D2 |

| 160 | 4 | 4 | 500 | 12 | 15 |

| 200 | 4 | 5 | 630 | 17 | 21 |

| 250 | 5 | 6 | 800 | 24 | 30 |

| 315 | 7 | 9 | 1000 | 33 | 43 |

| 400 | 9 | 11 | 1250 | 52 | 67 |

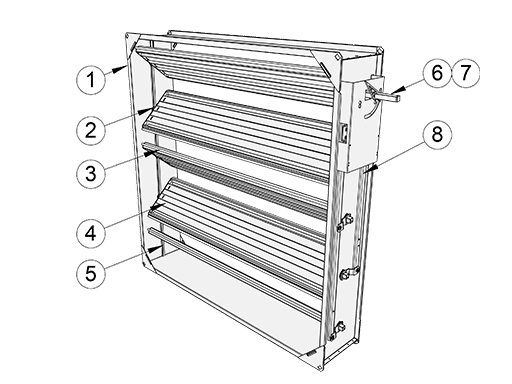

Structure and Materials

| No. | Part | Material | Note |

| 1 | Casing | Galvanised steel | Acid proof steel (AISI 316L) also available |

| 2 | Blade bearings | Alloy of polyamide and molybdenum suphide (plastic BM=ST). | Also available: |

| Stainless steel (AISI 304) (BM=SS) | |||

| Acid proof steel (AISI 316) (BM=AS) | |||

| Bronze JN5 (BM=BR) | |||

| 3 | Blade gaskets | Silicone | Heat-proof model: LTE silicone |

| 4 | Blades | Galvanised steel | (sandwich design). Acid proof steel (AISI 316L) also available |

| 5 | Gasket inside the casing | Silicone | Only tight UTT and UTX dampers. Gasket fixed in an aluminium profile |

| 6 | Rectangular drive shaft (15x15mm) | Galvanised steel | In conjunction with standard plastic bearings (BM=ST) |

| Acid proof steel (AISI 316) also available (BM=ST) | |||

| 7 | Round drive shaft (ø15mm) | Acid proof steel | In conjunction with AISI 316 or bronze bearings (BM=AS/SS/BR) |

| 8 | Lever mechanism | Galvanised steel | Acid proof steel (AISI 316L) also available |

Shaft types and dimensions

Depending on the choice of bearing material, the damper will be equipped with a round or square axle.

On Halton UTT/R dampers with standard bearings (BE=ST) , the damper will be equipped with a square 15×15 mm galvanised steel axle.

On heatproof design Halton UTT/R dampers, and on all dampers with AISI316/304 or bronze JN5 bearings (BM=AS, BM=SS or BM=BR) a round Ø15mm AISI 316 stainless steel axle will be used.

Accessories

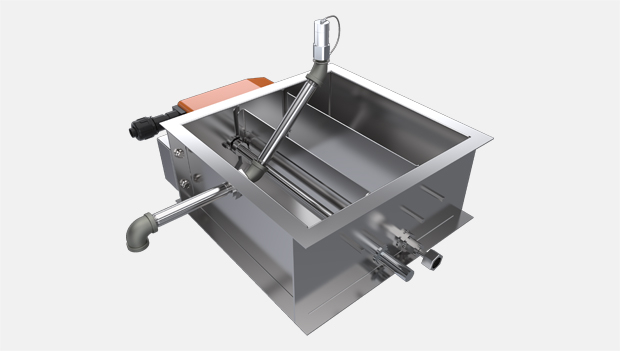

The product models MD=I and MD=J have a double sheet casing with mineral wool insulation. The insulation thickness is 20 mm.

The Halton UTT damper is available equipped with either manual adjustment or actuator operation.

The adjustment and control arrangement options are:

| Adjustment and control options | Code | Note |

| Manual handle adjustment | MO = MA | |

| Manual extension bar adjustment | AC = BA | Handle extension arrangement |

| Actuator operation | MO= | See tables below |

The damper actuator is selected from the list below according to the

operating voltage, control arrangement and the required torque of the damper.

The torque of the selected actuator can be higher than the required torque of the damper.

Standard actuator options

NM-models

Torque, damper size … 10 Nm (A<1.2 m2)

Manual override operation,mechanical position limit

| Actuator type | Code MO | Control arrangement | Operating voltage | Power consumption |

| NM24A | C1 | On-off, 3-point | AC/DC 24 V | 3,5 VA |

| NM230A | C2 | On-off, 3-point | AC 230 V | 5,5 VA |

| NM24A-SR | C3 | Control modulating DC 2…10 V, Position feedback 2…10 V | AC 24 V | 4 VA |

BFN-models

Torque, damper size … 9 Nm (A<1.2 m2)

Spring return, manual operation, position limit

| Actuator type | Code MO | Control arrangement | Operating voltage | Power consumption |

| BFN24-HL | M1 | On-off, 2 auxiliary switches | AC/DC 24 V | 6 VA |

| BFN230-HL | M2 | On-off, 2 auxiliary switches | AC 230 V | 10 VA |

BF-models

Torque, damper size …18 Nm / 12 Nm (A<2.5 m2)

Spring return, manual operation, position limit

| Actuator type | Code MO | Control arrangement | Operating voltage | Power consumption |

| BF24 | E1 | On-off, 2 auxiliary switches | AC/DC 24 V | 10 VA |

| BF230 | E3 | On-off, 2 auxiliary switches | AC 230 V | 12,5 VA |

| BF120 | E7 | On-off, 2 auxiliary switches | AC 120 V | 12,5 VA |

SF-models

Torque, damper size … 20 Nm (A<4 m2)

Spring return, manual operation, position limit

| Actuator type | Code MO | Control arrangement | Operating voltage | Power consumption |

| SF24A | A6 | On-off | AC/DC 24 V | 7,5 VA |

| SF24A-S2 | A7 | On-off, 2 auxiliary switches | AC/DC 24 V | 7,5 VA |

| SFA | A8 | On-off | AC 24…240V / DC 24….125 V | 18 VA |

| SFA-S2 | A9 | On-off, 2 auxiliary switches | AC 24…240V / DC 24….125 V | 18 VA |

| SF24A-SR | A0 | Control modulating DC 2…10 V, Position feedback 2…10 V | AC/DC 24 V | 7 VA |

| SF24A-MP | A11 | Control modulating, communicative 2…10 V, Position feedback 2…10 V variable | AC/DC 24 V | 11 VA |

SM-models

Torque, damper size … 20 Nm (A<3.3 m2)

Manual override operation, mechanical position limit

| Actuator type | Code MO | Control arrangement | Operating voltage | Power consumption |

| SM24A | A1 | On-off, 3-point | AC/DC 24 V | 4 VA |

| SM24A-S | A2 | On-off, 3-point, 1 auxiliary switch | AC/DC 24 V | 4 VA |

| SM230A | A3 | On-off, 3-point | AC 230 V | 6 VA |

| SM230A-S | A4 | On-off, 3-point, 1 auxiliary switch | AC 230 V | 6 VA |

| SM24A-SR | A5 | Control signal DC 0…10 V, Position feedback 2…10V | AC/DC 24 V | 4 VA |

| SM24A-MA | M3 | Control modulating 4…20 mA, Position feedback 2…10 V | AC/DC 24 V | 6 VA |

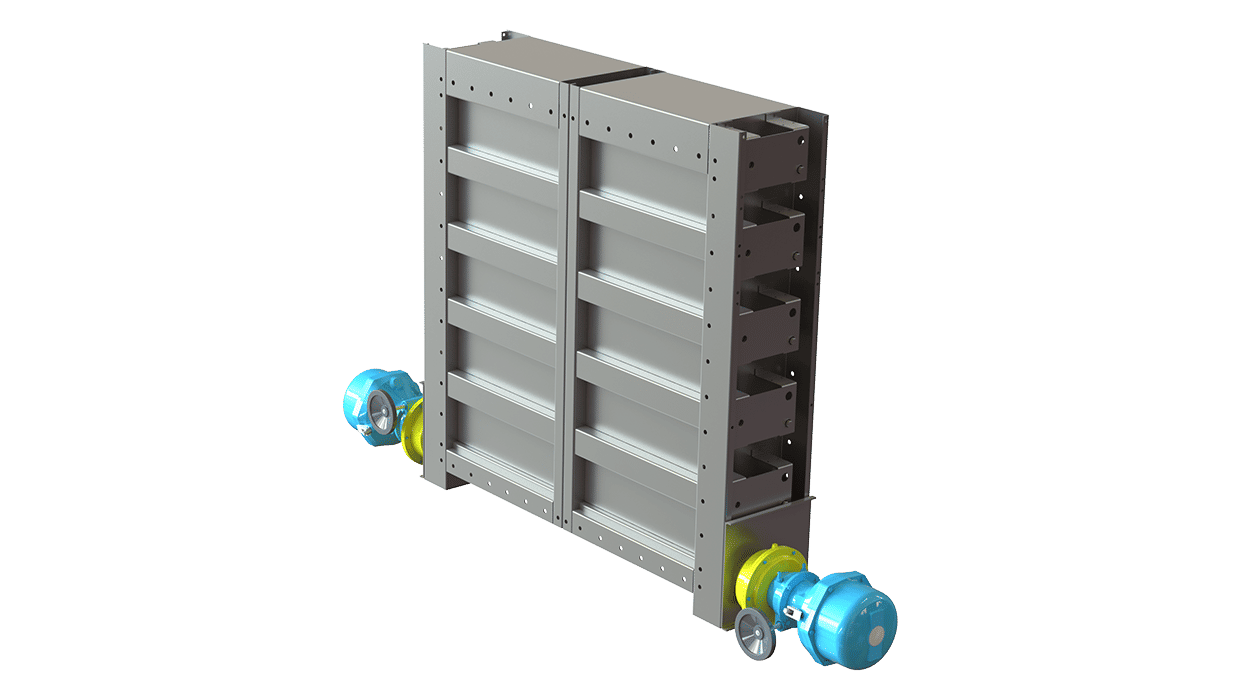

GM-models Torque, damper size …40 Nm (A<6 m2)

Manual override operation

| Actuator type | Code MO | Control arrangement | Operating voltage | Power consumption |

| GM24A | G1 | On-off, 3-point | AC/DC 24 V | 6 VA |

| GM230A | G2 | On-off, 3-point | AC 230 V | 9 VA |

Special actuators

| Actuator type | Code MO | Control arrangement | Operating voltage | Power consumption |

| InMax-15-SF | M4 | On-off, Spring return, 2 auxiliary switches | VAC/DC 24…240 V | – |

| NFA-S2 (10Nm) Halogen free cable |

M5 | On-off, Spring return, 2 auxiliary switches | AC 24…240 V/DC 24…125 V | 9,5 VA |

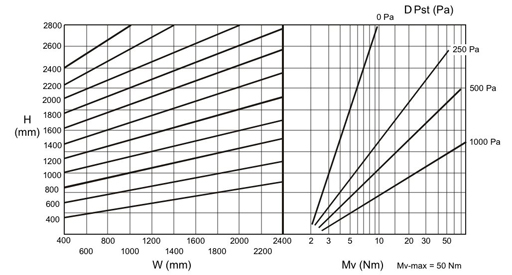

Required torque for Halton UTT-damper actuator

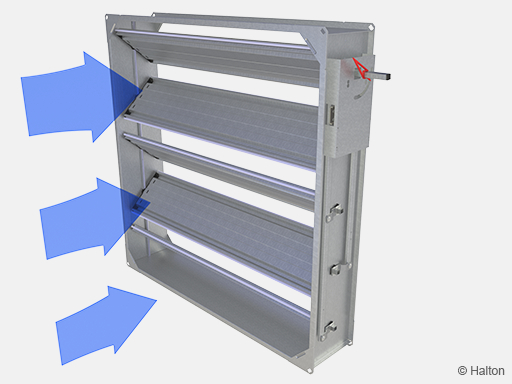

Operating principle

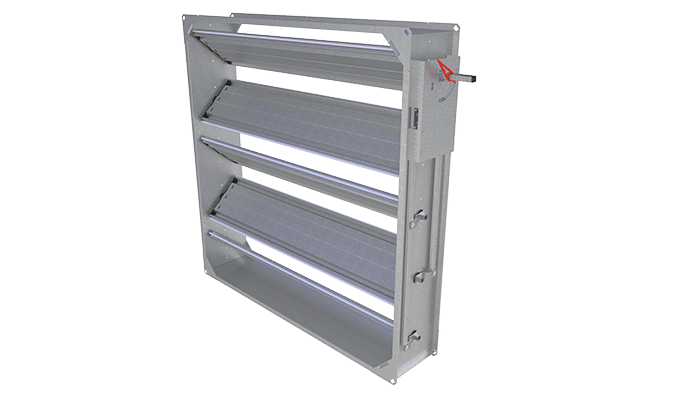

The Halton UTT dampers are used to shut off or control airflow in ductwork where tightness, thermal insulation and reliability are important.

In the closed position the Halton UTT damper leakage class is 3 in accordance with the EN1751 standard.

In the open position the blades are turned in the direction of flow and do not cause significant pressure losses.

Damper sizes conform with the international standards EN 1505, EN1506 and ISO 1707 for rectangular and circular ducts.

The maximum operation temperature of a standard damper is +100°C (for optional models +200°C).

Heat transmission of the damper is 6 W/(m 2 K).

Installation

Install the damper in the ductwork with the blades in horisontal or vertical position.

Fasten the damper in the ductwork using slip joints (SF=NA).

Optional models enable fastening the damper to duct flange by using bolts (SF=R2).

Drill holes in the damper flange if necessary (options SF=L1 / SF=L2).

Use a seal between the flanges in order to tighten the seam.

Fasten the models with circular connections by riveting or screwing.

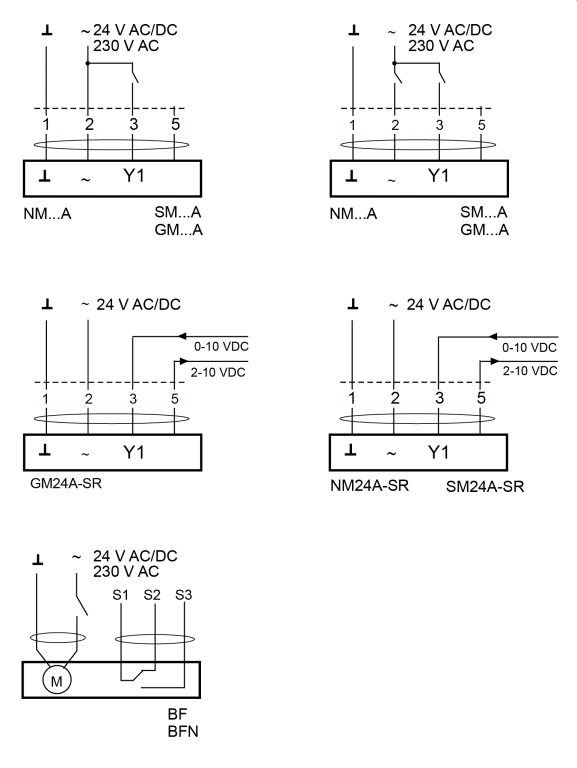

Wiring:

Specification

Function

Heat transmission of the damper does not exceed 6 W/(m2K).

The damper is suitable for either manual adjustment or actuator operation.

Materials

The casing and blades are made from galvanised steel or stainless steel (EN 1.4404/AISI 316L).

The blade gaskets are made of silicon (or EPDM- rubber).

The drive shaft socket is made of galvanised steel with self-lubricating slide bearings.

The bearing is made from an alloy of polyamide and molybdenum sulphide (or stainless steel AISI 316 or stainless steel AISI 304 or bronze).

Standards

The damper is installed into rectangular ducts in compliance with EN 1751, or in circular ducts D=100 …1250mm in accordance with EN 1751.

The damper meets the tightness requirements of EN 1751 class 3.

The casing of the damper meets the tightness requirements of EN 1751 class B.

Order code

UTT-S-W-H-D; CT-SF-MA-MD-BM-MO-AC-ZT

| Main options | |

| S = Type of duct connections | |

| R | Rectangular connections |

| C | Circular connections |

| W = Width [mm] | 100, +50, …, 2400 |

| H = Height [mm] | 100, +50, …, 2400 |

| D = Connection size for circular model [mm] | 100, 125, 160, 200, 250, 315, 400, 500, 630, 710, 800, 1000, 1250 |

| Other options and accessories | |

| CT = Type of circular connection | |

| D1 | 1 circular connection |

| D2 | 2 circular connections |

| SF = Flange option | |

| NA | Slip joints |

| L1 | Slip joints + flange connection |

| L2 | Flange connection, both sides |

| R2 | Flange connection, both sides with holes |

| P1 | Flange P30 |

| P2 | Flange P30 with FDL drilling |

| P3 | Flange connection with FDL drilling (Marine) |

| MA = Material | |

| CS | Steel |

| AS | Stainless steel (EN 1.4404/AISI 316L) |

| MD = Model | |

| N | Standard |

| H | Heat-proof |

| I | Insulated |

| J | Heat-proof and insulated |

| BM = Bearing material | |

| ST | Plastic |

| AS | Stainless steel (AISI 316) |

| SS | Stainless steel (AISI 304) |

| BR | Bronze (JN5) |

| MO = Actuator | |

| NA | Not assigned |

| MA | Manual handle |

| E1 | BF24 (no fuse), 24V, 18 Nm |

| E3 | BF230 (no fuse), 230V, 18 Nm |

| E7 | BF120 (no fuse), 120V, 18 Nm |

| M1 | BFN24-HL (no fuse), 24V, 9 Nm / 7 Nm |

| M2 | BFN230-HL (no fuse), 230V, 9 Nm / 7 Nm |

| P0 | Pneumatic, Rot.AT101 |

| A1 | SM24A (on-off), 24V, 20 Nm |

| A2 | SM24A-S (on-off), 24V, 20 Nm |

| A3 | SM230A (on-off), 230V, 20 Nm |

| A4 | SM230A-S (on-off), 230V, 20 Nm |

| A5 | SM24A-SR (modulating), 24V, 20 Nm |

| A6 | SF24A (on-off), 24V, 20 Nm |

| A7 | SF24A-S2 (on-off), 24V, 20 Nm |

| A8 | SFA (on-off), AC 24-240V/DC 24-125V, 20 Nm |

| A9 | SFA-S2 (on-off), AC 24-240V/DC 24-125V, 20 Nm |

| A0 | SF24A-SR (modulating), 24V, 20 Nm |

| A11 | SF24A-MP (modulating), 24V, 20 Nm |

| C1 | NM24A (on-off), 24V, 10 Nm |

| C2 | NM230A (on-off), 230V, 10 Nm |

| C3 | NM24A-SR (modulating), 24V, 10 Nm |

| M3 | SM24A-MA (modulating), 24V, 20 Nm |

| G1 | GM24A (on-off), 24V, 40 Nm |

| G2 | GM230A (on-off), 230V, 40 Nm |

| M4 | InMax-15-SF, VAC/DC 24…240 V, 15 Nm |

| M5 | NFA-S2, AC 24-240V/DC 24-125V, 10 Nm |

| K1 | FIC actuator |

| AC = Accessories | |

| BA | Bar adjustment |

| S4 | S2A Auxiliary switch |

| L1 | Limit switch, 1 pc (IP65) |

| L2 | Limit switch, 2 pcs (IP65) |

| AR | Position indication arrow |

| WH | Connector (Marine/Wieland) |

| WB | Connector (Marine/Wieland Blue1, MAC) |

| TG | Tag |

| ZT = Tailored product | |

| N | No |

| Y | Yes (ETO) |

Order code example

UTT-R-100-100-250; CT= D1, SF=NA, MA=CS, MD=N, BM=ST, MO=MA, AC=BA, ZT=N

Downloads

-

Halton UTT – Multi-blade airflow management damper (CAV)

Data

en

-

Halton UTT – Monisäleinen ilmavirran säätöpelti (CAV)

Data

fi

-

Halton UTT – Registre de réglage étanche à lames opposées (CAV)

Data

fr

-

Halton UTT – Luft- und wärmedichte Jalousieklappe

Data

de

-

Halton UTT – Jalusispjäll (CAV)

Data

se

-

Halton UTT – Fiche technique

Data

fr_FR

"*" indicates required fields