Product / PTS

Overview

- Shut-off, adjustment, balancing or control damper

- Casing leakage classification: EN 1751, Class C

- Casing and damper blade made of galvanized steel

- Tightness classification of shut-off damper: EN 1751, Class 4 (PTS/A model)

Product models and accessories

- Shut-off, adjustment, balancing or control damper

- Adjustment, balancing or control damper

- Adjustment, balancing or control damper with perforated blade

- Several actuator options

Quick selection

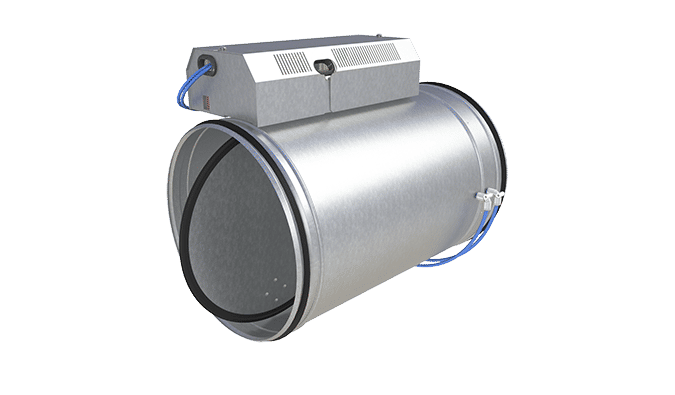

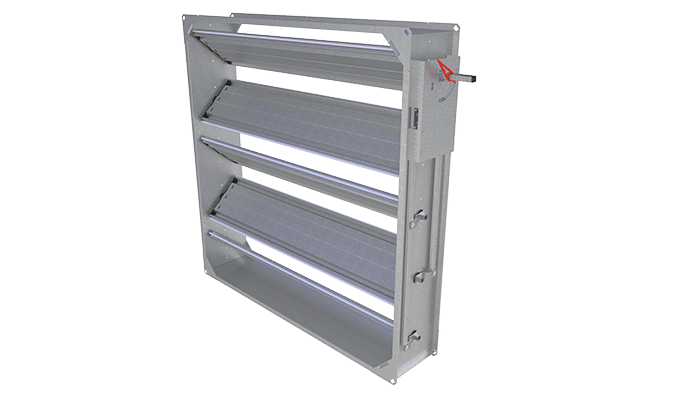

Fig.1. Halton PTS with blade gasket (A)

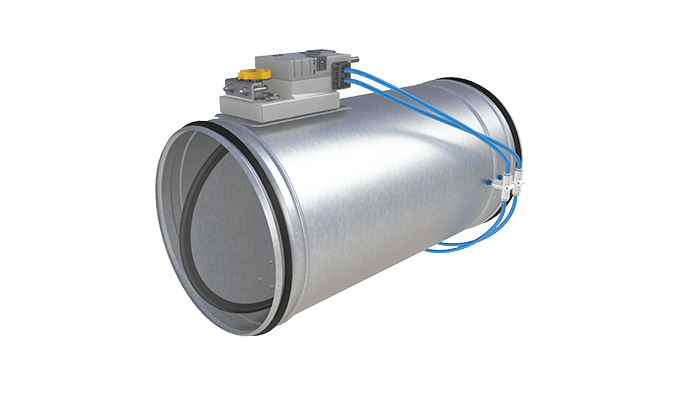

Fig.2. Halton PTS without blade gasket (B)

Fig.3. Halton PTS perforated blade (C)

Dimensions and weight

| NS [mm] |

L [mm] |

L1 [mm] |

L2 [mm] |

ØD [mm] |

| 100 | 145 | 70 | 36 | 99 |

| 125 | 145 | 70 | 36 | 124 |

| 160 | 145 | 70 | 36 | 159 |

| 200 | 145 | 70 | 36 | 199 |

| 250 | 145 | 70 | 36 | 249 |

| 315 | 145 | 70 | 36 | 314 |

| 400 | 245 | 175 | 35 | 399 |

| 500 | 245 | 175 | 35 | 499 |

Actuator platform, low (ML)

Actuator platform, high (MH)

Weight [kg]

| NS | PTS/A | PTS/B | PTS/C |

| 100 | 0.5 | 0.5 | 0.5 |

| 125 | 0.6 | 0.6 | 0.6 |

| 160 | 0.8 | 0.7 | 0.7 |

| 200 | 1.1 | 0.9 | 0.8 |

| 250 | 1.5 | 1.1 | 1.1 |

| 315 | 2.1 | 1.5 | 1.4 |

| 400 | 3.3 | 2.4 | |

| 500 | 4.9 | 3.6 |

Material

| No. | Part | Material | Note |

| 1 | Operating mechanism |

Galvanised steel | – |

| 2 | Actuator platform | Galvanised steel | – |

| 3 | Duct gaskets | 1C-polyurethane hybrid | – |

| 4 | Casing | Galvanised steel | – |

| 5 | Blade and shaft | Galvanised steel | – |

| 6 | Blade gasket | EPDM rubber | Used only in PTS/A model |

Product models

There are three different product models, for different purposes:

- Shut-off, adjustment, balancing or control damper, PTS/A. Tightness classification: EN 1751, Class 4

- Adjustment, balancing or control damper, PTS/B

- Adjustment, balancing or control damper with perforated blade, PTS/C

Minimum torque

| Model and size [mm] | 4 Nm | 10 Nm |

| PTS/A 100…250 | x | |

| PTS/A 315…500 | x | |

| PTS/B 100…500 | x | |

| PTS/C 100…500 | x |

Manual operation

Handle for manual operation with blade position locking.

Actuator options

Standard actuators:

| Code | Name | Manufac. | Torque Nm |

Power supply |

Control type |

Power consuption |

| B1 | LM24A | Belimo | 5 | 24 VAC/VDC | On-off, 2-wire | 3 VA/2 W |

| B2 | LM230A | Belimo | 5 | 230 VAC | On-off, 2-wire | 12 VA/1 W |

| B3 | LM24A-SR | Belimo | 5 | 24 VAC/VDC | Modulating 0…10 VDC |

4 VA/2 W |

| B4 | NM24A | Belimo | 10 | 24 VAC/VDC | On-off, 2-wire | 3.5 VA/2 W |

| B5 | NM230A | Belimo | 10 | 230 VAC | On-off, 2-wire | 18 VA/2 W |

| B6 | NM24A-SR | Belimo | 10 | 24 VAC | Modulating 0…10 VDC |

3 VA/1.5 W |

| B7 | LF24 | Belimo | 4 | 24 VAC | On-off, spring return | 7 VA/5 W |

| B8 | LF230 | Belimo | 4 | 230 VAC | On-off, spring return | 7 VA/5 W |

| X1 | GDB111.1E/KN | Siemens | 5 | 24 VAC | KNX bus | 1 VA/0.5 W |

| X2 | GLB111.1E/KN | Siemens | 10 | 24 VAC | KNX bus | 3 VA/2.5 W |

| X3 | GDB161.1E | Siemens | 5 | AC/DC 24 V | Modulating | 2.1 VA/1.2W |

| X4 | GLB161.1E | Siemens | 10 | AC/DC 24 V | Modulating | 2.5 VA/1.5W |

| X5 | GDB141.1E | Siemens | 5 | AC/DC 24 V | 2/3 position | 2.5 VA/1.1W |

| X6 | GLB141.1E | Siemens | 10 | AC/DC 24 V | 2/3 position | 2.0 VA/1.3W |

| V5 | LM24A-VST | Belimo | 5 | AC/DC 24 V | Control communicative PP | 2 VA/1 W |

| V6 | NM24A-VST | Belimo | 10 | AC/DC 24 V | Control communicative PP | 4 VA/2 W |

| M1 | BFN24 (Marine) | Belimo | 9/7 | AC/DC 24 V | On-off, spring return | 6 VA/4 W |

| M2 | BFN230 (Marine) | Belimo | 9/7 | 230 VAC | On-off, spring return | 9 VA/4.5 W |

| M3 | SM24A-MA-C7 (Marine) | Belimo | 20 | AC/DC 24 V | Modulating 4…20 mA |

6 VA/3.5 W |

| M4 | InMax-15-SF (Marine) | Schischek | 15/30 | 24…240 VAC/DC | On-off, spring return, 3-point | – |

If other actuator types are required, consult Halton in order to specify the type and manufacturer.

After sales installation of the actuator

Actuator installation on the site is possible with the help of an actuator bed and extension shaft. This enables installation of a universal actuator type. The actuator bed selected can be of standard type when the ductwork is not insulated or of high type if the ductwork is insulated.

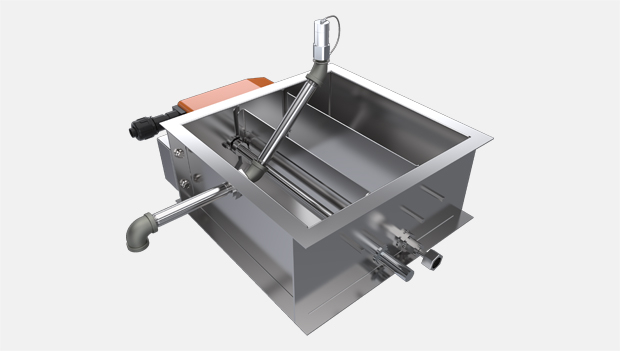

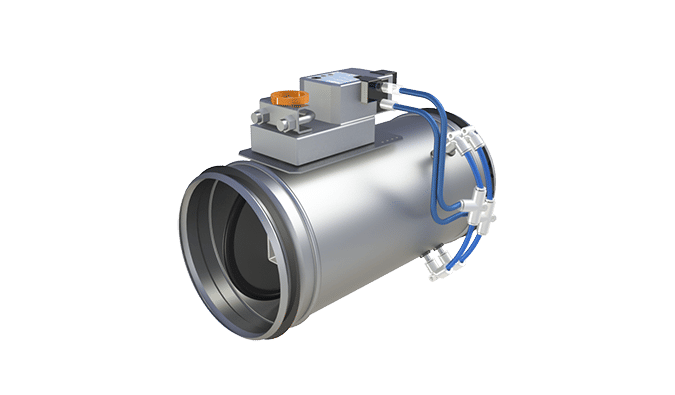

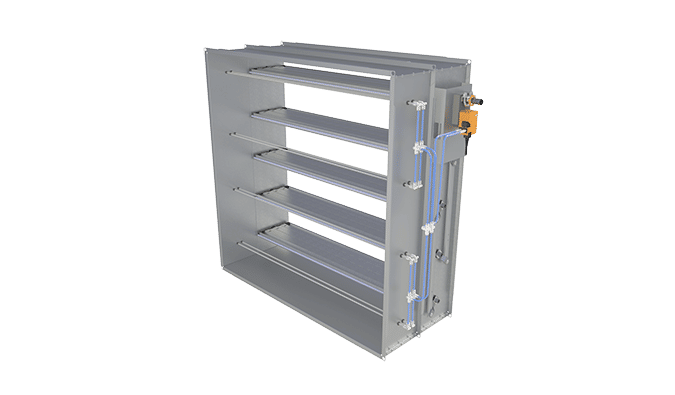

Fig.1. Halton PTS/A with actuator (B4 = NM24A)

Fig.2. Actuator with installation kit low (IL) and high (IH)

Function

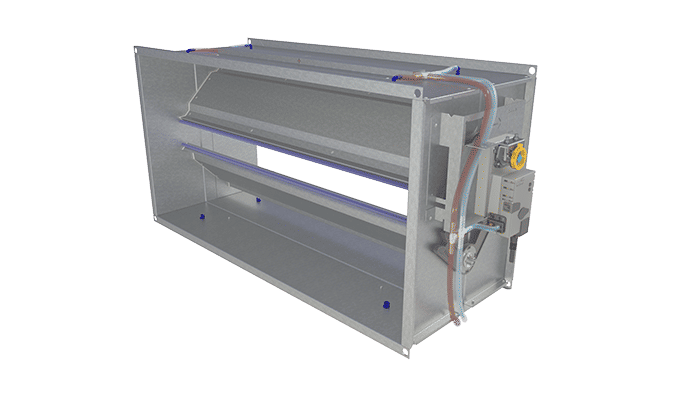

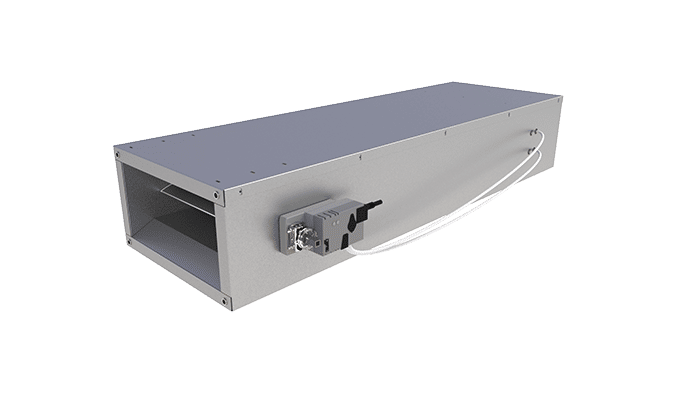

The Halton PTS unit can operate as a shut-off, control or adjustment damper depending on the product model. This damper is available for circular standard duct sizes 100 mm to 500 mm. Damper position is visually indicated below the operating mechanism.

The Halton PTS/A is a shut-off damper of leakage class 4 according to the EN 1751 standard. It includes rubber gaskets to ensure low leakage flow when the damper is in closed position. The PTS/A is available with a handle for manual operation or with an electric actuator for on-off control or for modulating control using a 0…10 VDC control signal.

The Halton PTS/B can be used for airflow control or adjustment of airflow rates in the ductwork. It includes a steel blade without gasket. The PTS/B is available with a handle for manual operation or with an electric actuator for on-off control or for modulating control using a 0…10 VDC control signal.

The Halton PTS/C is an airflow adjustment damper. The damper blade is a perforated blade that is acoustically and operationally designed for balancing of airflow rates.

The electric actuator is normally installed in the factory on the actuator platform with screws. On-site actuator installation is possible with the help of an actuator installation kit. The actuator installation kit, available as an accessory, includes an actuator platform and extension shaft for universal actuator fixing. The actuator platform and actuator can be installed easily using standard hand tools.

Halton PTS/A

Halton PTS/B

Halton PTS/C

Installation

Fasten the damper to the ductwork with, e.g., rivets. Ensure that the rivets do not prevent the operation of the damper. The position of each rivet must be at least 10 mm from the duct end.

External duct gaskets ensure an airtight joint when the damper has been mechanically fastened to the duct with rivets or screws.

The electric actuator (where applicable) is to be connected to the power supply and control signal wires according to the wiring diagram. Examples of connections for the standard actuators are shown in a separate diagram.

The electric actuator can also be installed, when necessary, in an on-site procedure with the help of an actuator platform and universal shaft fitting, available as an accessory:

Remove the operating mechanism (1) by opening the locking screw.

Assemble the actuator platform in the location of the operation mechanism (2) and ensure its stability mechanically by bending the legs of the actuator platform with a hand tool.

The universal actuator fitting enables connection of most actuator types to the shaft (3) (4).

Wire connections are to be performed according to the instruction for the actuator installed.

Electric wire connections

Belimo

Specification

The casing and circular (perforated) blade of the shut-off / adjustment / control damper shall be made of galvanised steel.

The shut-off damper shall meet EN 1751, Class 4 tightness requirements.

External rubber gaskets on the spigot shall provide an airtight connection to circular ductwork.

Order code

PTS-S-D; MA-MO-AC-ZT

S = Model

A Damper with blade gasket

B Damper without blade gasket

C Damper with perforated blade

D = Duct connection size [mm]

100, 125, 160, 200, 250, 315, 400, 500

Other options and accessories

MA = Material

CS Steel

MO = Actuator type

MA Manual handle

B1 LM24A, 24 VAC/VDC (on-off), 5 Nm

B2 LM230A, 230 VAC (on-off), 5 Nm

B3 LM24A-SR, 24 VAC/VDC (modulating), 5 Nm

B4 NM24A, 24 VAC/VDC (on-off), 10 Nm

B5 NM230A, 230 VAC (on-off), 10 Nm

B6 NM24A-SR, 24 VAC/VDC (modulating), 10 Nm

B7 LF24, 24 VAC/VDC (on-off, spring return), 4 Nm

B8 LF230, 230 VAC (on-off, spring return), 4 Nm

X1 GDB111.1E/KN (KNX bus), 5 Nm

X2 GLB111.1E/KN (KNX bus), 10 Nm

X3 GDB161.1E AC/DC 24 V, (modulating), 5 Nm

X4 GLB161.1E AC/DC 24 V, (modulating), 10 Nm

X5 GDB141.1E AC/DC 24 V, (2/3 position), 5 Nm

X6 GLB141.1E AC/DC 24 V, (2/3 position), 10 Nm

V5 LM24A-VST, (DC 0/2…10 V), 5 Nm

V6 NM24A-VST, (DC 0/2…10 V), 10Nm

M1 BFN24 (Marine)

M2 BFN230 (Marine)

M3 SM24A-MA-C7 (Marine)

M4 InMax-15-SF (Marine)

NA Not assigned

AC = Accessories

BA Bar adjustment

ML Actuator platform, low

MH Actuator platform, high

IL Installation kit for actuator, low

IH Installation kit for actuator, high

IJ Actuator platform (for LF actuator)

WB Connector (Marine/Wieland Blue1, MAC)

WM Connector (Marine/Wieland Blue2, MAC)

ZT = Tailored product

N No

Y Yes (ETO)

Order code example

PTS-A-160; MA=CS, MO=B1, AC=ML, ZT=N

Downloads

-

Halton PTS – Airflow management damper (single-blade)

Data

en

-

Halton PTS – Ilmavirran säätöpelti (yksiläppäinen)

Data

fi

-

Halton PTS – Registre de réglage étanche

Data

fr

-

Halton PTS – Drosselklappe

Data

de

-

Halton PTS – Spjäll (enbladig)

Data

se

-

浩盾PTS-C圆形单叶调节阀

Data

cn

-

Halton PTS – Fiche technique

Data

fr_FR

"*" indicates required fields