Product / KSK

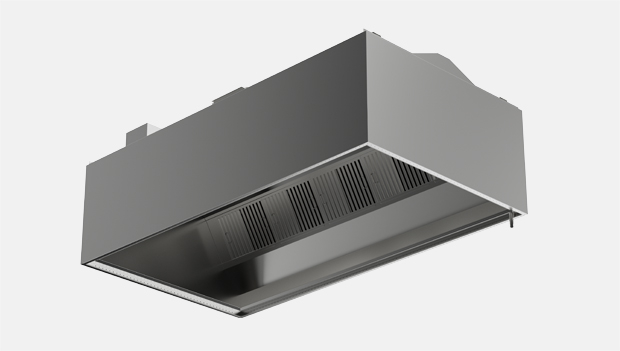

KSK – Capture Jet Type I Exhaust Hood for Industrial, Cook-Chill & Island Applications

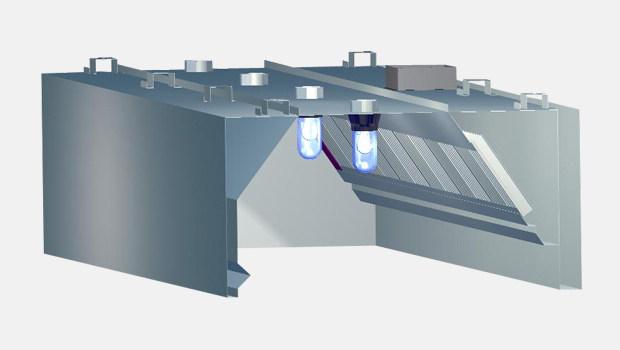

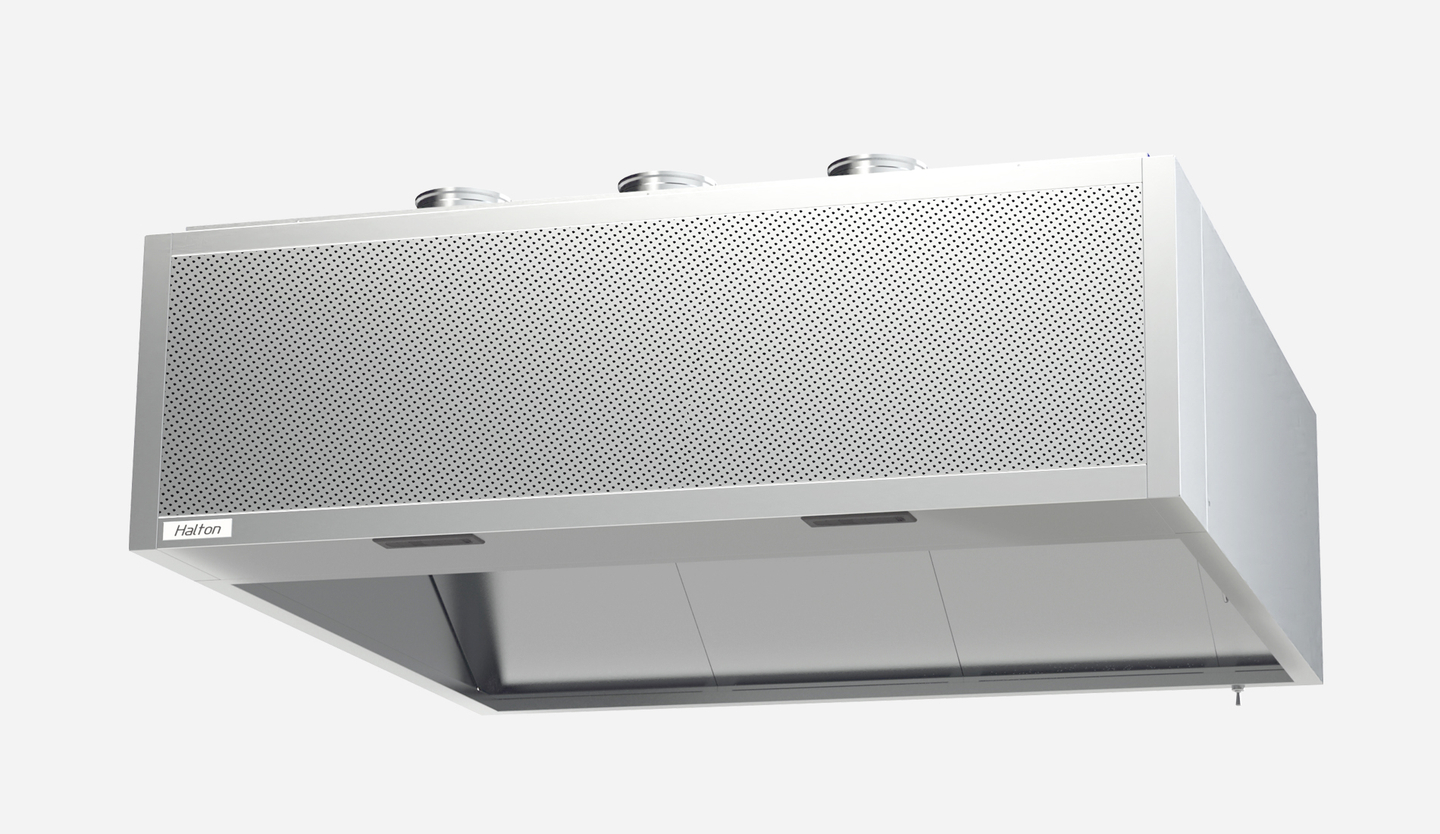

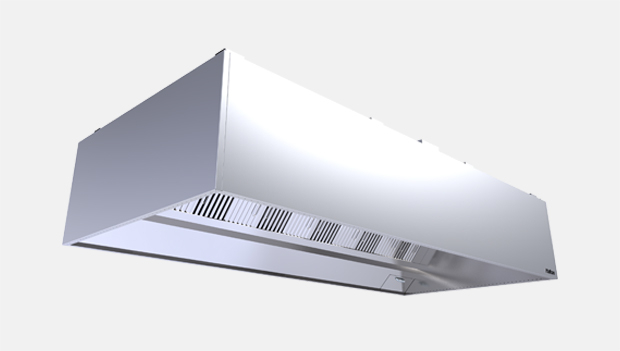

The Halton KSK Capture Jet Hood is a Type I exhaust hood designed for continuous-duty kitchens, from industrial cooking to cook-chill production, and for island lineups with challenging capture conditions. Featuring Halton Capture Jet™ technology, it effectively contains grease-laden vapors, smoke, steam, and heat while lowering exhaust airflow requirements, improving energy efficiency and operator comfort.

Why These Kitchens Demand More from a Hood

Production kitchens are not “single duty.” Loads shift station-to-station and moment-to-moment, and many operations run continuously. In these environments, ventilation performance can be impacted by:

- Mixed processes occurring side-by-side (grease-heavy and moisture-heavy operations in one line)

- Batch events that create plume surges (dumping, boiling, rapid cycling)

- High traffic and open exposure are common in island layouts, increasing the risk of cross drafts

Halton’s KSK is designed for these realities, helping maintain predictable capture and containment where conventional solutions can struggle.

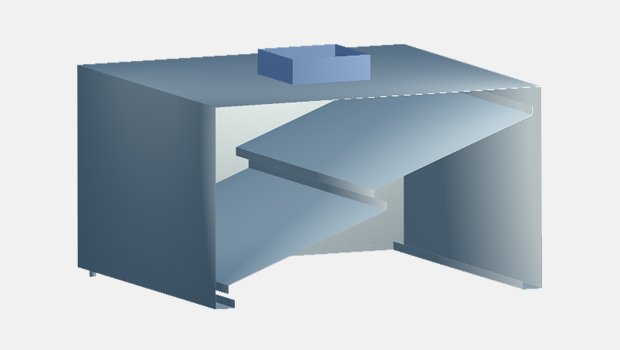

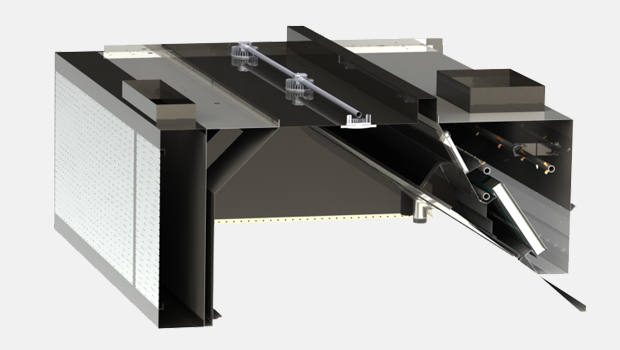

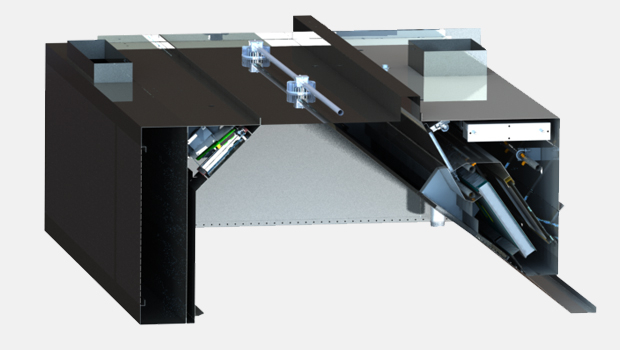

How It Works

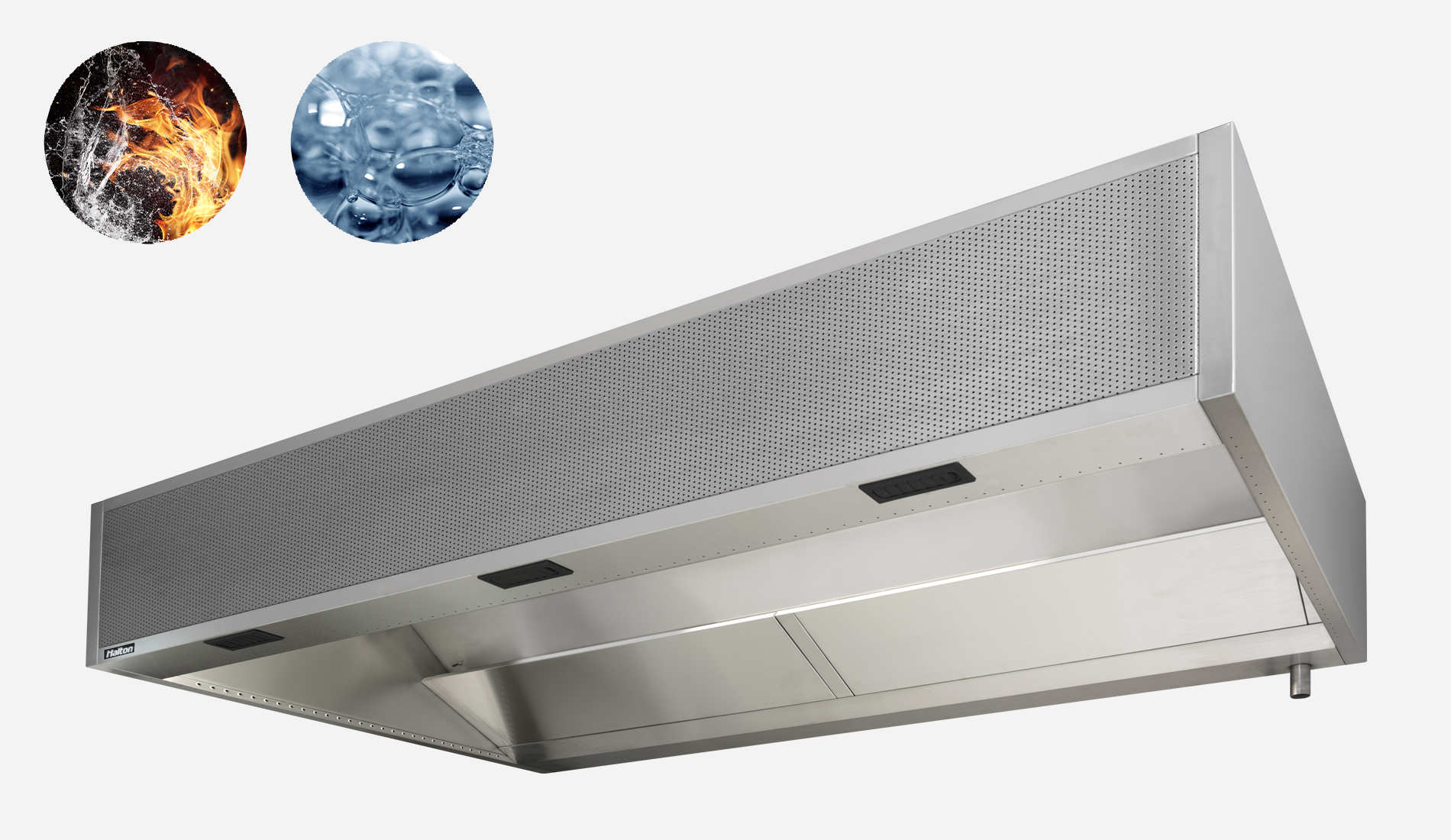

Halton’s KSK is designed to capture and remove grease-laden vapors, smoke, and heat generated by high-intensity cooking across industrial and cook-chill production lines. It supports mixed-duty operations, including equipment that releases significant moisture/steam, helping maintain capture performance in layouts and operating conditions that can challenge standard hoods. With Capture Jet™ technology, a controlled air stream is introduced along the exposed perimeter to stabilize the capture zone and improve containment of steam, heat, and effluent, which can reduce the exhaust airflow required to maintain performance, especially valuable in high-humidity, high-temperature industrial and cook-chill environments.

KSK Performance Highlights

- Up to 30%-40% exhaust airflow reduction vs. conventional hoods

- Built to manage continuous high‑moisture and high steam production, helping reduce condensation buildup and eliminate dripping onto work surfaces.

- Engineered to excel in challenging island configurations, maintaining stable capture even in environments with cross‑drafts and exposed airflow conditions

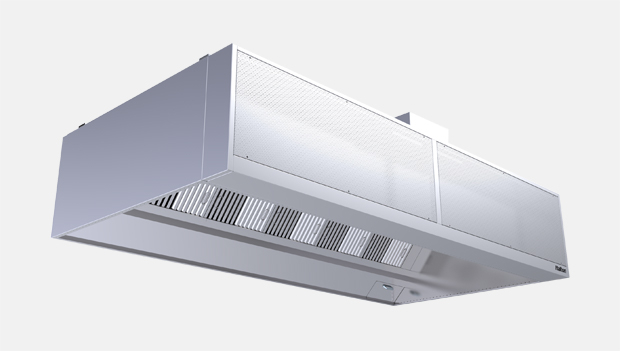

- High‑efficiency KSA multi‑cyclone filters, up to 95% removal at 10 microns per ASTM F2519

- Integrated T.A.B. ports for accurate testing, balancing, and commissioning

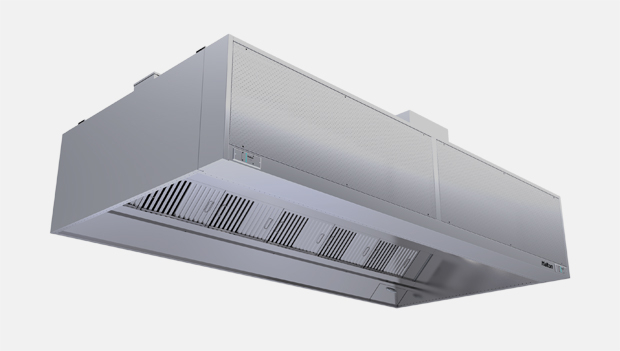

- Optional suspended hoist rail support for cook‑chill or industrial cooking workflows

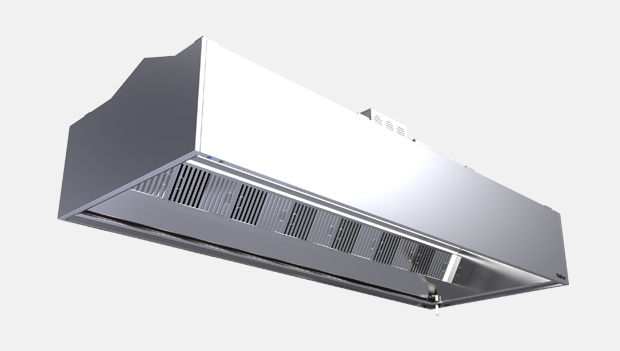

- Stainless steel welded construction with LED or Halton HCL Culinary Light options

- Optional M.A.R.V.E.L. Demand Controlled Kitchen Ventilation for real‑time airflow optimization

Ideal Applications

- Industrial cooking lines and high-output production kitchens

- Cook-chill production and batch process environments

- Mixed-duty lines combining multiple cooking methods and equipment types

- Island cooking suites with challenging airflow dynamics

- Institutional and central production kitchens where hygiene and safety are critical

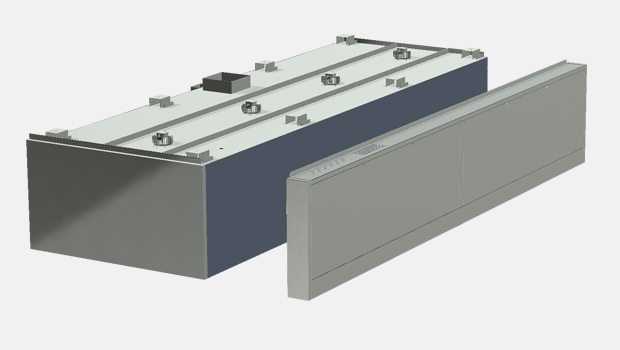

Options & Accessories

- Closure panels (for canopies below ceiling level)

- Backsplash

- Side skirts

- Hoist rail accommodation available

- KFR filter removal tool

- Lighting options:

- Standard LED

- Dimmable LED

- Halton HCL Culinary Lights

- MEP master electrical panels

- Face or remote‑mounted switch panels

- Factory pre‑piped fire protection

- Hood‑mounted fire cabinet

- Finishes: powder coating; custom stainless steel textures/finishes

- Controls:

- M.A.R.V.E.L. Demand Controlled Kitchen Ventilation

Recommended Combinations

Build Your Complete System

- Energy efficiency / Demand Control Kitchen Ventilation: M.A.R.V.E.L.

- Pollution control / location flexibility: PolluStop

- Fire protection: Factory pre‑installed FSS Fire Suppression System

FAQ's

When should I specify KSK instead of a standard Type I canopy hood?

Specify KSK when the operation is continuous-duty, the line is mixed-process, or the layout includes island conditions where capture and containment can be harder to maintain.

Is KSK suitable for cook-chill production kitchens?

Yes. KSK is engineered for demanding production environments where loads vary and processes shift throughout the day.

Why are island cooking lines more challenging to ventilate?

Island suites are more exposed to cross drafts, traffic movement, and open pathways, which can disrupt capture if the hood and air strategy aren’t aligned.

What equipment is KSK commonly specified over?

KSK is often used over kettles, tilting skillets/braising pans, and mixed-duty cooking lines where process conditions create variable plume behavior.

What information do you need to support selection and coordination?

Equipment list, duty profile, wall vs island layout, ceiling height, makeup air approach, code requirements, and any site constraints (odor, adjacency, hours, etc.).

Downloads

Contact Us

Talk to an Expert About Your Line Layout

If you’re designing an industrial or cook-chill kitchen or coordinating a complex island suite, Halton can support layout review and documentation.

Our team looks forward to hearing from you. Please fill in the form. We’ll be in touch with you shortly.

"*" indicates required fields