Product / TRS

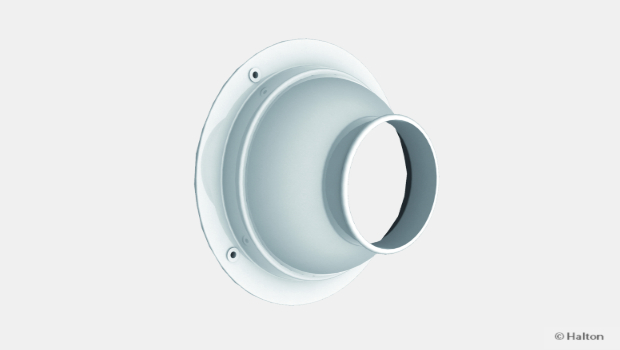

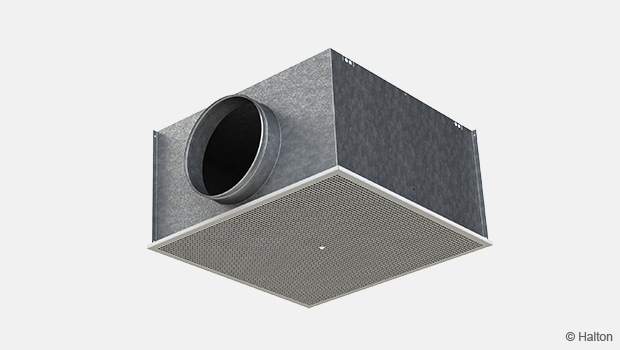

Halton TRS – Compact/conical diffuser

Ideal for high spaces.

- Specially designed for large enclosures

- Horisontal adjustable throw pattern with compact jet position

Link to Revit object (MagiCAD Cloud)

Overview

- Specially designed for large enclosures

- Horizontal adjustable throw pattern with compact jet position

- Alternative throw patterns are selected by rotating the cone module

- Long throw pattern with low velocity reduction

- Alternative wide and short shape throw pattern

- Circular duct connection

Quick selection

Fig.1. Halton TRS with compact jet, narrow

Fig.1. Halton TRS with compact jet, narrow

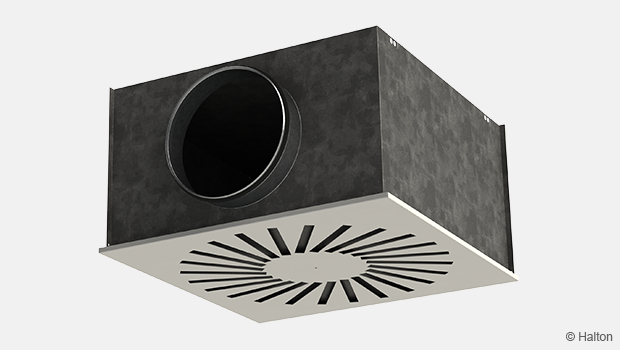

Fig.2. Halton TRS with compact jet, wide

Fig.2. Halton TRS with compact jet, wide

Dimensions

| NS | H | H1 Wide |

H1 Narrow |

H2 | ØD | ØD1 |

| 200 | 90 | 100 | 85 | 28 | 159 | 198 |

| 250 | 114 | 130 | 110 | 35 | 199 | 248 |

| 315 | 140 | 155 | 130 | 39 | 249 | 313 |

| 400 | 170 | 190 | 140 | 40 | 314 | 398 |

| 500 | 208 | 245 | 165 | 43 | 399 | 498 |

Weight

| NS | kg |

| 200 | 1.00 |

| 250 | 1.53 |

| 315 | 2.44 |

| 400 | 3.39 |

| 500 | 5.40 |

Material

| Part | Material | Note |

| Casing | Steel | – |

| Cone module | Steel | – |

| Finishing | Painted, White (RAL 9003/30% gloss) |

Special RAL colour available |

Accessories

| Accessory | Code | Description |

| Balancing plenum | TRI | For balancing, equalising the airflow and attenuating the duct noise (polyester fibre) |

| Balancing plenum | TRH | For balancing, equalising the airflow and attenuating the duct noise (mineral wool and polyester fibre) |

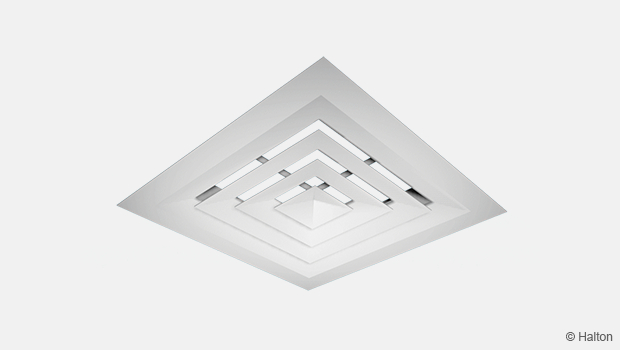

Function

Narrow jet Wide jet

Air is supplied to the space through the selectable cone module

The supply air pattern can be selected for wide or narrow jet by rotating the cone module.

The narrow compact jet is used for long air pattern in heating applications and the conical wide jet for shorter air pattern in cooling applications.

The angle for narrow air pattern can be adjusted.

Installation

| NS | ØD1 |

| 200 | 198 |

| 250 | 248 |

| 315 | 313 |

| 400 | 398 |

| 500 | 498 |

The diffuser is connected either directly to the duct by screwing or by riveting or alternatively to the Halton TRI balancing plenum.

The recommended minimum safety distance upstream of the diffuser is 3xD.

Installation with Halton TRI

The collar of Halton TRI plenum can be installed either internally in the plenum or externally onto the bottom of the plenum. The height of the unit for the external installation is presented in the table below. When the collar is installed internally, the total height H4 is reduced by 60 mm.

Note: The technical performance for the combination of supply air diffuser and plenum is presented separately for the two different installations.

| NS | TRI (ØD2-ØD) | H3 | H4 |

| 200 | TRI-160-200 | 130 | 249 |

| 250 | TRI-200-250 | 160 | 289 |

| 315 | TRI-250-315 | 220 | 339 |

| 400 | TRI-315-400 | 265 | 403 |

Adjustment

The Halton TRS itself has no means for airflow adjustment.

In order to enable airflow adjustment and measurement of airflow rate it is recommended that the diffuser be connected to the Halton TRI balancing plenum. The supply flow rate is determined by using the MSM measurement and adjustment module.

Pass the tubes and control spindle through the cone module of the diffuser.

Measure the differential pressure using a manometer. The flow rate is calculated using the formula below.

Adjust the airflow rate by rotating the control spindle until the desired setting is achieved. Lock the damper position with a screw.

Replace the tubes and spindle in the plenum.

The k-factor for installations with different safety distances

(D= duct diameter)

| TRI | > 8 x D | min 3 x D |

| 100 | 6.0 | 7.5 |

| 125 | 9.9 | 12.6 |

| 160 | 16.9 | 21.9 |

| 200 | 28.3 | 31.0 |

| 250 | 47.9 | 51.5 |

| 315 | 78.6 | – |

Servicing

Wipe the diffuser with a damp cloth.

Option with balancing plenum

Detach the diffuser from the plenum.

Remove the measurement and adjustment module by gently pulling out the shaft (NB. not the control spindle or measurement tubes!).

Wipe the parts with a damp cloth, instead of immersing in water.

Reassemble the measurement and adjustment module by pushing in the shaft back into place until the unit meets the stopper.

Reinstall the diffuser.

Specification

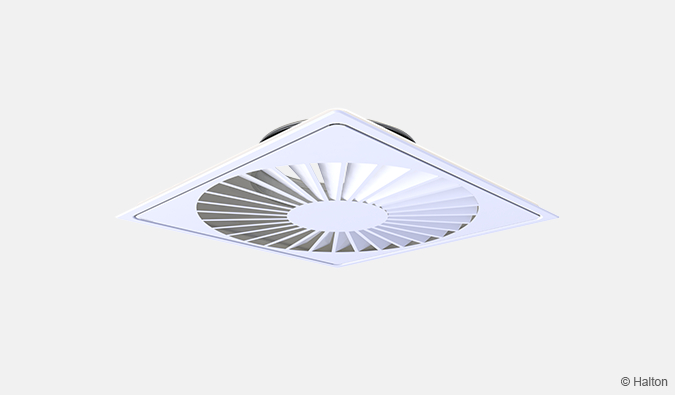

The diffuser is made of painted steel with a white (RAL 9003) colour.

The diffuser is made in two sections: an outer sleeve and an inner concentric cone.

The supply air pattern is selectable for wide or narrow jet by rotating the cone module.

The angle of narrow supply air pattern is adjustable.

Order code

TRS-D; CO-MO-ZT

D = Connection size

200, 250, 315, 400, 500

Other options and accessories

CO = Colour

SW White (RAL 9003)

X Special colour (RAL xxxx)

MO = Actuator type

NA Not assigned

M1 LM24A SR

ZT = Tailored product

N No

Y Yes (ETO)

Sub products

TRI Plenum

TRH Plenum

Code example

TRS-200, CO=SW, MO=NA, ZT=N

Downloads

"*" indicates required fields